Components Of Distribution Board

Top sponsor listing

Top sponsor listing

1/24

1/24

1/4

1/4

1/20

1/20

CN

CN

1/27

1/27

1/29

1/29

1/39

1/39

About components of distribution board

Where to Find Components of Distribution Board Suppliers?

Global sourcing for components of distribution boards is heavily concentrated in China, where specialized manufacturing clusters in Fujian, Zhejiang, and Shanghai offer competitive advantages in production scale, supply chain integration, and technical adaptability. Fujian and Shanghai host advanced automation-focused facilities, while Yuyao (Zhejiang) and surrounding regions form a dense ecosystem for electrical component manufacturing, supplying over 70% of low-voltage power distribution hardware exported globally.

These industrial zones benefit from vertically integrated production networks—encompassing die-casting, sheet metal fabrication, busbar processing, and final assembly—within compact geographic radii. This localization reduces component lead times by 25–40% compared to offshore alternatives and enables rapid prototyping for customized enclosures, branding, and circuit configurations. Buyers gain access to suppliers capable of delivering small batches (as low as 1 piece) or high-volume orders with consistent quality control, supported by mature logistics infrastructure for air and sea freight consolidation.

How to Choose Components of Distribution Board Suppliers?

Selecting reliable suppliers requires rigorous evaluation across three core dimensions:

Technical and Functional Compliance

Verify adherence to international standards such as IEC 61439 (low-voltage switchgear), CE marking, and RoHS compliance for material safety. For critical applications, confirm compatibility with ATS (Automatic Transfer Switch), VFD (Variable Frequency Drive), and PLC-based control systems. Request detailed schematics, single-line diagrams, and enclosure IP ratings (e.g., IP55 for outdoor use) to ensure design alignment.

Production and Customization Capacity

Assess supplier capabilities through the following benchmarks:

- In-house engineering teams supporting customization of busbar layout, metering (voltmeter/ammeter integration), branding, and enclosure dimensions

- Minimum monthly output capacity exceeding 5,000 units for standard MCB panels or fuse boxes

- Advanced processing techniques including CNC punching, laser cutting, and powder coating for durable finishes

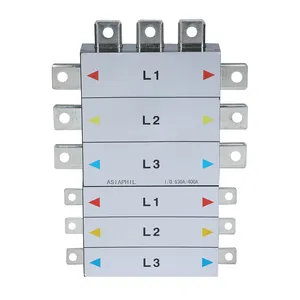

Cross-reference customization claims with actual product listings showing configurable parameters such as phase count (single/three-phase), current rating (up to 400A), and modular slot arrangements.

Transaction Reliability and Quality Assurance

Prioritize suppliers demonstrating proven performance metrics:

- On-time delivery rate ≥97%

- Response time under 4 hours for inquiry resolution

- Reorder rate above 25% indicating customer retention

Utilize documented transaction histories and verified revenue tiers (e.g., $180,000+ annual online sales) as proxies for operational stability. Conduct factory audits via video walkthroughs to validate equipment calibration, testing procedures (dielectric strength, thermal rise), and inventory management practices.

What Are the Best Components of Distribution Board Suppliers?

| Company Name | Main Products | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Fujian Guozhiyun Information Technology Co., Ltd. | Power Distribution Equipment, UPS, Enclosures | Enclosure design, transformer capacity, automation drawings, labeling, graphic layouts | $250,000+ | 100% | ≤1h | 66% | 1 pc | Varies |

| YUEQING BARFUSE ELECTRIC CO., LTD | MCB Panels, Busbars, Fuses, Push Buttons | Limited; standard configurations only | $3,000+ | 100% | ≤10h | 25% | 1–20 pcs | $4.33–42.31 |

| Shanghai WINYAN Automation Systems Co., Ltd. | Distribution Cabinets, PLC-Controlled Systems | Full OEM/ODM support, PLC programming, VFD integration | Not specified | 100% | ≤2h | - | 5 pcs | $50–3,000+ |

| Ningbo Haishu Efon Communication Equipment Limited | Fiber Optic Distribution Boxes, Plastic Enclosures | Branding, hole patterns, color options | $180,000+ | 100% | ≤2h | 23% | 20 pcs | $8.80–$22.00 |

| Dongguan Hsk Rc Technology Co., Ltd. | Mini Power Distribution Boards (PDBs) for Drones | Basic voltage/output variations | $60,000+ | 97% | ≤4h | 29% | 10–50 pcs | $0.50–$10.00 |

Performance Analysis

Fujian Guozhiyun stands out with the highest reorder rate (66%) and fastest response time (≤1 hour), combined with extensive customization capabilities across materials, labeling, and system automation—ideal for buyers requiring tailored power distribution solutions. Shanghai WINYAN specializes in industrial-grade PLC-integrated cabinets, targeting automation projects with budgets starting at $1,000 per unit. YUEQING BARFUSE offers cost-effective standard components like MCB pans and busbars, suitable for bulk procurement at entry-level pricing. Ningbo Efon serves telecom infrastructure needs with fiber-optic-compatible enclosures, while Dongguan Hsk caters to niche electronics markets such as drone PDBs. Suppliers with 100% on-time delivery records dominate the sector, reflecting mature logistics planning and order tracking systems.

FAQs

How to verify components of distribution board supplier reliability?

Cross-check declared certifications (CE, ISO) with official databases or request copies of test reports from accredited labs. Evaluate supplier credibility through verifiable transaction volume, customer reviews focused on post-delivery support, and consistency in product specifications across multiple listings.

What is the typical lead time for custom distribution board components?

Standard products ship within 7–15 days. Custom designs involving new enclosures, wiring diagrams, or branding require 20–35 days, depending on complexity. Prototypes for validation can be produced within 10–14 days upon approval of technical drawings.

Do suppliers support OEM/ODM for distribution board components?

Yes, leading manufacturers offer full OEM/ODM services including logo printing, custom packaging, schematic design, and material selection. Minimum order quantities vary: 5–50 units for complex assemblies, lower for standardized parts.

What are common materials used in distribution board components?

Enclosures are typically made from cold-rolled steel (SECC), stainless steel, or polycarbonate (for outdoor/weatherproof models). Internal components use copper or aluminum busbars, thermoplastic housings for MCBs, and insulating barriers meeting UL94 V-0 flame ratings.

Are samples available before placing bulk orders?

Most suppliers provide samples at reduced cost, often refundable against future orders. Sample pricing ranges from 30% to 100% of unit cost, with shipping fees applicable. Expect 5–10 days for dispatch after payment confirmation.