Components Of Distribution Transformer

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

TW

TW

CN

CN

About components of distribution transformer

Where to Find Suppliers for Components of Distribution Transformers?

China remains a central hub for manufacturing components of distribution transformers, with key production clusters in Henan, Shandong, and Anhui provinces. These regions host vertically integrated supply chains specializing in magnetic cores, windings, insulation systems, and structural enclosures. Luoyang in Henan Province is recognized for advanced coil winding and core stacking technologies, while Shandong's Zibo and Jinan areas leverage proximity to steel and copper processing facilities, reducing material lead times by up to 25%. Anhui’s Hefei region focuses on precision electrical components, particularly toroidal and gapped transformer cores used in oil-immersed and dry-type units.

The industrial ecosystems support rapid prototyping and scalable production, enabling suppliers to fulfill both bulk orders and customized configurations. Most manufacturers operate within 50km of component vendors, testing labs, and logistics hubs, ensuring efficient coordination across the production cycle. Buyers benefit from competitive pricing—driven by localized sourcing of silicon steel, copper wire, and insulating materials—as well as lead times averaging 30–45 days for standard configurations. Custom-built units may require 60–75 days depending on technical complexity.

How to Choose Suppliers for Components of Distribution Transformers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Material Compliance

Confirm supplier capability to meet IEC 60076 and IEEE C57.12.00 standards for load loss, no-load loss, impedance, and thermal performance. Key materials—including grain-oriented silicon steel (CRGO), high-purity copper windings, and temperature-resistant insulation (e.g., Nomex, epoxy resin)—must be traceable and compliant with RoHS and REACH regulations where applicable. Request test reports for dielectric strength, short-circuit withstand, and partial discharge levels.

Production Capacity Verification

Assess infrastructure through documented benchmarks:

- Minimum factory area of 3,000m² for dedicated transformer assembly lines

- In-house capabilities for core cutting, coil winding, vacuum pressure impregnation (VPI), and tank fabrication

- Use of automated winding machines and gap-cutting equipment for consistent core performance

Cross-reference online revenue indicators and order fulfillment history with on-time delivery rates (target ≥95%) to validate operational stability.

Quality Assurance & Transaction Security

Prioritize suppliers with ISO 9001-certified quality management systems. For export markets, verify CE or KEMA certification if required. Utilize secure payment mechanisms that align with delivery milestones. Conduct pre-shipment inspections to validate winding resistance, turns ratio, and insulation integrity. Sample testing should include no-load current measurement and temperature rise tests under rated conditions.

What Are the Leading Suppliers for Components of Distribution Transformers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Key Materials Handled |

|---|---|---|---|---|---|---|---|

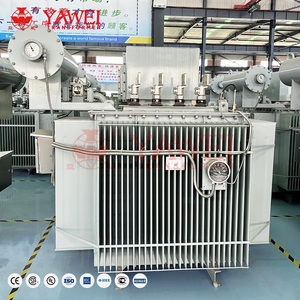

| Luoyang Xinghe Special Type Transformer Co., Ltd. | Transformers, MV&HV Switchgear, Power Distribution Equipment | HV/LV configuration, core material, winding type, labeling, oil-immersed design | 100% | ≤4h | <15% | US $640,000+ | Silicon steel, copper, insulating oil, enclosure materials |

| Shandong Beidian Electric Co., Ltd. | Distribution Transformers (50–3150kVA), Oil-Immersed Units | Voltage rating, phase count, efficiency level, packaging | 100% | ≤1h | - | - | CRGO steel, copper/aluminum windings, radiators, bushings |

| Wuxi Weibang Transformer Manufacture Co., Ltd. | Transformer Cores (Toroidal, Gapped, R-Core), Magnetic Components | Core geometry, lamination thickness, gap size, coating | 100% | ≤3h | 30% | US $60,000+ | Silicon steel tape, ferrite, copper wire |

| Hefei Qixing Electric Appliance Co., Ltd. | Medium/High-Voltage Transformers, Custom Voltage Units | Voltage input/output, outdoor rating, core design | 100% | ≤3h | - | - | Iron cores, copper coils, insulation materials |

| Ningbo Pengyuejia Electrical Appliance Co., Ltd. | High-Frequency Transformers, Electronic Power Transformers | Frequency range, power rating, PCB mounting type | 66% | ≤5h | 100% | US $3,000+ | Ferrite cores, enameled copper wire, bobbins |

Performance Analysis

Luoyang Xinghe and Shandong Beidian demonstrate strong engineering control with full-unit manufacturing and customization depth, supported by 100% on-time delivery records. Wuxi Weibang specializes in high-precision magnetic cores, offering critical subcomponents essential for low-loss transformer designs. Hefei Qixing provides responsive service and tailored voltage solutions, ideal for niche applications. Ningbo Pengyuejia, while exhibiting lower on-time performance, shows a 100% reorder rate, indicating customer satisfaction in electronic transformer segments. Suppliers with documented customization parameters—such as phase count, load loss, and winding material—offer greater flexibility for grid-specific deployments.

FAQs

What certifications should transformer component suppliers have?

Essential certifications include ISO 9001 for quality management. For international compliance, look for IEC 60076 series validation, CE marking (for EU), or KEMA test reports. Environmental standards like RoHS apply to insulating materials and coatings.

What are typical MOQs and pricing ranges?

MOQs vary: core components start at 100–500 pieces ($0.39–$50/unit), while complete distribution transformers often require 1 unit minimum, priced between $950 and $16,220 based on kVA rating, cooling type, and efficiency class.

Can suppliers provide custom design and labeling?

Yes, leading manufacturers offer full OEM/ODM services, including custom nameplates, HV/LV configurations, energy efficiency grading (e.g., Level 2), and client-specific packaging and labeling.

How to verify material quality before procurement?

Request material test certificates (MTCs) for core steel (e.g., B-H curve data) and copper conductivity. Conduct third-party lab checks on sample windings for purity and insulation dielectric strength. On-site audits should include raw material storage and traceability systems.

What logistics options are available for global shipping?

Most suppliers support FOB, CIF, and DDP terms. Complete transformers are typically shipped via sea freight due to weight and volume. Air freight is viable for urgent core or coil component deliveries. Ensure proper crating and moisture protection for long-distance transport.