Composite Machining Tools

1/13

1/13

1/11

1/11

1/15

1/15

1/17

1/17

About composite machining tools

Where to Find Composite Machining Tools Suppliers?

China remains a dominant force in the production of composite machining tools, with key manufacturing clusters located in Fujian, Shandong, Guangdong, and Shaanxi provinces. These regions host specialized industrial ecosystems that integrate precision engineering, material science, and advanced CNC processing capabilities. Xiamen and Dongguan serve as hubs for high-precision custom machining services, while Jinan and Xi’an have developed expertise in cutting tool design and carbide-based tooling solutions for composite materials such as carbon fiber, aluminum composites, and laminates.

The concentration of technical suppliers within these zones enables vertically integrated production cycles—from raw material sourcing to final tool assembly—reducing lead times by up to 25% compared to decentralized manufacturing models. Suppliers benefit from proximity to metallurgical facilities, logistics networks, and skilled labor pools, allowing them to maintain competitive pricing and scalability. Buyers can expect standard order fulfillment within 15–30 days, depending on customization complexity, with production costs typically 20–35% lower than equivalent Western manufacturers due to optimized supply chains and energy-efficient processing methods.

How to Choose Composite Machining Tools Suppliers?

Selecting reliable suppliers requires rigorous evaluation across three core dimensions:

Technical Expertise and Material Compatibility

Verify that suppliers possess documented experience in machining advanced composite materials, including PCD (polycrystalline diamond) tooling for abrasive substrates. Confirm compatibility with target materials—such as CFRP (carbon fiber reinforced plastic), GFRP, or aluminum composite panels (ACP)—through technical specifications and application case studies. Suppliers should demonstrate proficiency in managing delamination, heat buildup, and tool wear during high-speed operations.

Production Infrastructure and Quality Assurance

Assess operational scale and process control through the following indicators:

- Minimum facility size exceeding 2,000m² for sustained output capacity

- In-house R&D or engineering teams supporting tool geometry optimization

- On-site CNC grinding, coating, and inspection equipment for quality consistency

Prioritize suppliers with verified quality management systems. While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates above 80% and repeat order ratios exceeding 30% indicate stable internal processes.

Customization and Transaction Reliability

Evaluate flexibility in handling OEM/ODM requests, including custom coatings, geometries, shank sizes, and packaging. Confirm digital drawing submission protocols and turnaround times for prototypes. Use response time (≤3 hours preferred) and reorder rate as proxies for customer service reliability. For risk mitigation, initiate small trial orders before scaling procurement.

What Are the Best Composite Machining Tools Suppliers?

| Company Name | Location | Verified Supplier Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Xiamen Yistar Precision Manufacturing Co., Ltd. | Fujian, CN | Multispecialty Supplier | CNC turning-milling composite parts, robotic arm accessories, 4-/5-axis components | US $970,000+ | 97% | ≤3h | 39% | 1 piece |

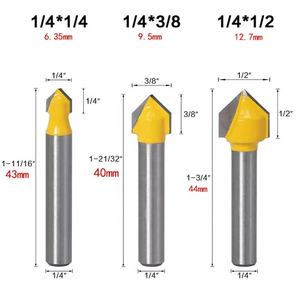

| Jinan Joseph Tool Manufacturing Co., Ltd. | Shandong, CN | Custom Manufacturer | Router bits for ACP, V-grooving tools, aluminum composite machining cutters | US $10,000+ | 100% | ≤1h | 16% | 10 units |

| Guangdong Tianyu Mechanical Equipment Co., Ltd. | Guangdong, CN | Not Specified | PCD diamond endmills, carbide milling cutters, drill bits, tool holders | US $60,000+ | 55% | ≤1h | 57% | 1 piece/box |

| Xi'an Huishan Shiyi Industry And Trade Co., Ltd. | Shaanxi, CN | Not Specified | Diamond router bits, solid carbide end mills, burr-style milling tools | US $30,000+ | 81% | ≤2h | 33% | 3–10 pieces |

| Dongguan Dayi Hardware Products Co., Ltd. | Guangdong, CN | Not Specified | CNC machining services, stainless steel components, sheet metal fabrication | US $2,000+ | 83% | ≤5h | 20% | 1 piece |

Performance Analysis

Xiamen Yistar stands out for high-volume export capability and strong after-sales performance, supported by a 97% on-time delivery rate and extensive customization options across materials, labeling, and technical drawings. Jinan Joseph excels in responsiveness (≤1h) and perfect delivery adherence, though its lower reorder rate suggests potential gaps in long-term client retention. Guangdong Tianyu demonstrates strong technical focus on PCD tooling with the highest reorder rate (57%), indicating customer satisfaction despite moderate delivery reliability (55%). Xi’an Huishan offers balanced performance with robust technical offerings and consistent fulfillment. Dongguan Dayi provides low-MOQ flexibility ideal for prototyping but operates at a smaller revenue scale. Buyers seeking high-precision, scalable supply should prioritize suppliers with proven track records in diamond-coated tooling and composite-specific cutting dynamics.

FAQs

What certifications should composite machining tool suppliers have?

While explicit ISO or CE certifications are not always disclosed, prioritize suppliers who reference standardized quality controls, provide technical drawings, and support product testing. Third-party verification via transaction platforms can substitute for formal audits in early engagements.

What is the typical MOQ for composite machining tools?

MOQs vary by supplier and tool type. Entry-level providers like Dongguan Dayi accept single-piece orders, ideal for sampling. Specialized tool manufacturers such as Jinan Joseph require minimum batches of 10 units, reflecting economies of scale in tool production.

How long does it take to receive samples?

Sample lead times range from 7–15 days for standard tools. Custom geometries or PCD-tipped cutters may require 20–25 days, including grinding and coating cycles. Air shipping adds 5–10 days internationally.

Can suppliers customize tool geometry and coatings?

Yes, most suppliers listed offer full customization—including flute design, helix angles, coatings (e.g., TiAlN, diamond), and shank configurations—based on technical drawings or application requirements. Turnaround for design validation is typically 48–72 hours.

Are there cost advantages in bulk ordering?

Bulk procurement yields significant unit cost reductions, especially for carbide and PCD tools. Suppliers like Jinan Joseph and Xi’an Huishan offer tiered pricing, with per-unit costs decreasing by 15–30% at volumes above 100 units. Negotiate bundled shipping and extended payment terms for larger contracts.