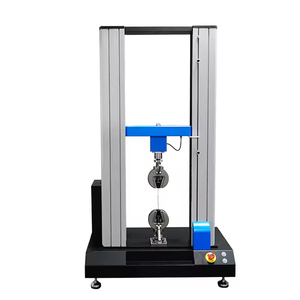

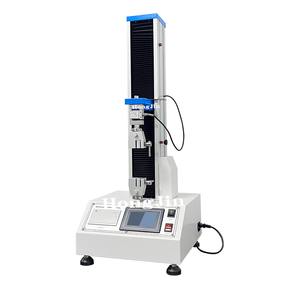

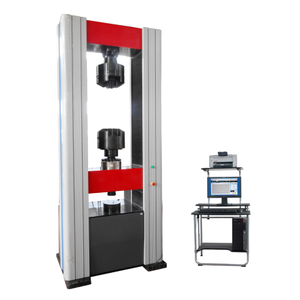

Computerized Tensile Testing Machine

Top sponsor listing

Top sponsor listing

1/27

1/27

1/14

1/14

1/14

1/14

1/11

1/11

1/8

1/8

1/40

1/40

About computerized tensile testing machine

Where to Find Computerized Tensile Testing Machine Suppliers?

China remains the global hub for computerized tensile testing machine manufacturing, with key production clusters concentrated in Shandong and Guangdong provinces. Jinan, the capital of Shandong, has emerged as a center for precision testing instrumentation, hosting specialized manufacturers with vertically integrated R&D and assembly capabilities. This region benefits from proximity to metallurgical and automotive industries, enabling rapid prototyping and application-specific customization.

Guangdong-based suppliers, particularly in Dongguan and Foshan, leverage advanced automation supply chains and export-oriented infrastructure to serve international laboratories and quality control facilities. These industrial ecosystems support high-volume production with streamlined component sourcing—particularly servo motors, load cells, and digital controllers—reducing lead times by up to 25% compared to non-specialized regions. Buyers gain access to flexible MOQs (as low as 1 set), competitive pricing models, and scalable output capacity, with many suppliers capable of fulfilling 50+ unit orders within 4–6 weeks.

How to Choose Computerized Tensile Testing Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Integration

Confirm that machines comply with international standards such as ISO 7500-1 (metallic materials – verification of static uniaxial testing machines) and ASTM E4 (standard practices for force verification). For regulated sectors (aerospace, medical devices), demand CE marking and documentation of software validation for computerized control systems. Verify compatibility with test types: tensile, compression, flexural, peel, and cyclic loading under variable temperature conditions.

Production Capability Assessment

Evaluate core manufacturing competencies through these indicators:

- Minimum factory area of 2,000m² indicating established operations

- In-house engineering teams supporting custom programming (e.g., stress-strain curve analysis, data export formats)

- Integrated calibration labs using traceable weights and certified sensors

Cross-reference online revenue data and on-time delivery performance (>98% recommended) to assess reliability and order fulfillment consistency.

Transaction Safeguards & Quality Assurance

Prioritize suppliers offering documented quality management systems (ISO 9001 preferred). Utilize secure payment mechanisms where funds are released only after equipment verification. Request sample testing reports including repeatability error (<±0.5%) and resolution accuracy. Conduct video audits to verify CNC machining centers, final assembly lines, and pre-shipment calibration procedures before committing to large orders.

What Are the Best Computerized Tensile Testing Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range |

|---|---|---|---|---|---|---|---|

| Jinan Kason Testing Equipment Co., Ltd. | Shandong, CN | Tensile Testing Machine, Hardness Testers, Compression Testing Machine | US $500,000+ | 100.0% | ≤3h | 33% | 14 models |

| Dongguan Haoen Automation Equipment Co., Ltd. | Guangdong, CN | Tensile Testing Machine, Drying Equipment, Weighing Scales | US $40,000+ | 100.0% | ≤2h | <15% | 5 models |

| Dongguan Hongjin Test Instrument Co., Ltd. | Guangdong, CN | Tensile Testing Machine, Hydraulic Presses, Colorimeter | - | 100.0% | ≤2h | - | 5 models |

| Jinan Fokstest Instrument Co., Ltd. | Shandong, CN | Tensile Testing Machine, Hardness Testers, Microscopes | US $10,000+ | 100.0% | ≤3h | <15% | 5 models |

| Guangdong Hongyu International Trade Co., Ltd. | Guangdong, CN | Tensile Testing Machine, Hydraulic Presses, Drying Equipment | US $80,000+ | 100.0% | ≤2h | 28% | 5 models |

Performance Analysis

Jinan Kason stands out with the highest reported online revenue (US $500,000+) and broadest product range (14 models), indicating strong market penetration and scalability. Its 33% reorder rate reflects consistent customer retention, likely driven by comprehensive testing solutions for metals and composites. Guangdong Hongyu demonstrates robust repeat business (28% reorder rate) and fast response times (≤2h), positioning it well for urgent procurement cycles.

Shandong-based suppliers dominate in structural design expertise, offering both single-column (microcomputer-controlled) and double-column (servo-hydraulic) configurations suitable for high-load applications (up to 1000kN). Dongguan-based manufacturers focus on compact, cost-effective units ideal for textile, plastic, and packaging QA labs. All listed suppliers maintain 100% on-time delivery records, but buyers should scrutinize reorder rates and technical specialization when selecting partners for long-term contracts or industry-specific requirements.

FAQs

How to verify computerized tensile testing machine supplier reliability?

Cross-check self-reported certifications (e.g., ISO, CE) with third-party verification where possible. Request calibration certificates with NIST-traceable references and review firmware version logs to confirm software updates and bug fixes. Analyze customer reviews focusing on post-installation support, system stability, and ease of integration with existing lab networks.

What is the typical lead time for standard and customized models?

Standard configurations ship within 15–25 days after order confirmation. Customized systems requiring modified grips, extended crossheads, or environmental chambers may require 30–45 days depending on complexity. Air freight adds 5–10 days globally; sea freight ranges from 20–40 days based on destination port.

Do suppliers offer customization options?

Yes, most suppliers support mechanical and software-level customization. Common requests include load capacity adjustments (10kN to 1000kN), integration with high/low-temperature chambers, multi-language UI interfaces, and data export via USB or Ethernet. Provide detailed specifications including test speed, displacement accuracy, and required compliance standards during inquiry.

What are the common MOQ and pricing ranges?

MOQ is typically 1 set, making these machines accessible for small labs and pilot projects. Pricing varies significantly by configuration: entry-level single-column testers start at $199–$800, mid-range servo-electric models range from $2,000–$9,000, while high-capacity hydraulic systems exceed $15,000. Bulk orders (10+ units) often qualify for 8–15% discounts and waived shipping fees.

Can suppliers provide installation and training support?

Many suppliers offer remote setup assistance via video call and provide multilingual user manuals, operation videos, and troubleshooting guides. On-site installation and technician training can be arranged at additional cost, typically quoted separately based on travel logistics and duration.