Continuous Casting Services

Top sponsor listing

Top sponsor listing

1/1

1/1

1/13

1/13

1/3

1/3

1/2

1/2

1/1

1/1

1/1

1/1

1/3

1/3

1/14

1/14

0

0

1/18

1/18

0

0

1/3

1/3

1/23

1/23

CN

CN

1/3

1/3

1/12

1/12

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

About continuous casting services

Where to Find Continuous Casting Services Suppliers?

China remains the central hub for continuous casting machinery and services, with key industrial clusters in Shaanxi, Henan, Guangdong, and Hebei provinces. These regions host integrated metallurgical equipment ecosystems supported by mature steel, aluminum, and copper processing industries. Xi'an and Luoyang in Shaanxi Province specialize in slab and billet casting systems, leveraging proximity to heavy industrial zones and research institutions focused on metal forming technologies. Dongguan and Wuxi serve niche markets such as jewelry and non-ferrous metal casting, offering compact, energy-efficient machines tailored for precision applications.

Suppliers benefit from vertically aligned supply chains—encompassing furnace manufacturing, CNC machining, and automation integration—enabling rapid prototyping and scalable production. The average factory in this sector operates over 5,000m² of production space, supporting both standard machine output and customized turnkey lines. Buyers can expect lead times ranging from 30 to 60 days depending on complexity, with cost advantages of 25–40% compared to European or North American manufacturers due to lower labor and material input costs.

How to Choose Continuous Casting Services Suppliers?

Selecting a reliable partner requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Process Expertise

Confirm alignment with international quality standards such as ISO 9001. While explicit certification data is not always disclosed, consistent on-time delivery rates (≥97%) and low dispute volumes indicate robust internal quality management. For applications involving high-temperature metals like steel or copper, verify design compliance with ASTM or DIN standards for thermal resistance, mold cooling efficiency, and strand withdrawal systems.

Production Capability Assessment

Evaluate supplier infrastructure using measurable indicators:

- Facility size exceeding 3,000m² to support full assembly lines

- In-house engineering teams capable of customizing molds, rollers, and automation controls

- Proven experience in delivering complete casting solutions (furnace-to-cooling bed integration)

Cross-reference listed product ranges with response time and reorder rate metrics. Suppliers with sub-4-hour response times and reorder rates above 50% demonstrate strong after-sales support and system reliability.

Customization & Transaction Security

Most suppliers offer extensive customization options including material type (steel, aluminum, brass, zinc), casting shape (slab, round/square billet, tube), capacity, and control system interface. Ensure clear documentation of design inputs via CAD drawings or process flow diagrams. Utilize secure payment mechanisms that release funds upon successful commissioning. Prioritize suppliers with transparent revenue reporting and verifiable shipping histories for cross-border transactions.

What Are the Best Continuous Casting Services Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Notable Equipment Offered |

|---|---|---|---|---|---|---|---|---|

| Luoyang Ruixinsheng Industrial Technology Co., Ltd. | Henan, CN | Metal Casting Machinery (157), Industrial Furnaces (799) | US $240,000+ | 100% | ≤1h | 66% | Material, size, drawing, logo, packaging, sand/iron casting | Full-automatic aluminum ingot casting, compact CC+rolling line |

| Tangshan Bohai Metallurgy Intelligent Equipment Co., Ltd. | Hebei, CN | Metal Casting Machinery (144), Industrial Furnaces (36) | Not specified | 100% | ≤4h | Not available | Limited data | Slab, square, and round billet CCMs with enhanced surface quality |

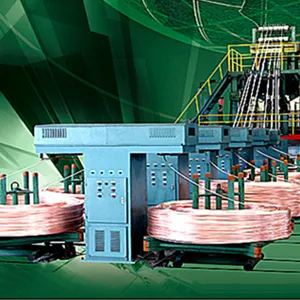

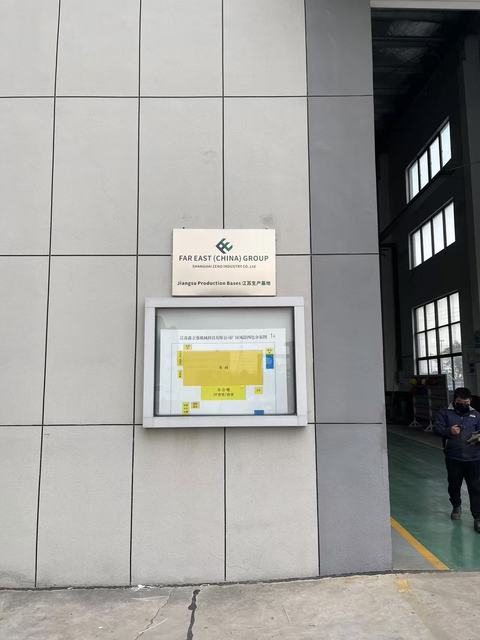

| Wuxi Jintong Furnace Co., Ltd. | Jiangsu, CN | CNC Lathe (109), Metal Casting Machinery (60) | US $140,000+ | 100% | ≤7h | Not available | Not specified | Horizontal continuous casting for copper, brass, zinc |

| Xi'an Hani Tech Co., Ltd. | Shaanxi, CN | Rolling Mills (937), Industrial Furnaces (799) | US $210,000+ | 100% | ≤4h | 20% | Color, material, size, logo, packaging, graphic label | Integrated casting and rolling production systems |

| Dongguan Cheuk Kay Jewelry Machinery Co., Ltd. | Guangdong, CN | Metal Casting Machinery (65), Die Casting Machine (28) | US $40,000+ | 60% | ≤5h | 25% | Graphic, label, packaging, logo | Centrifugal spin casting machines for jewelry and small parts |

Performance Analysis

Luoyang Ruixinsheng stands out with a 66% reorder rate and one-hour average response time, indicating high customer satisfaction and operational agility. Tangshan Bohai offers specialized large-scale casting machines for slab and billet production, backed by 100% on-time delivery despite limited public financial data. Wuxi Jintong focuses on horizontal casting systems for non-ferrous metals, catering to wire rod and tube producers requiring energy-efficient solutions. Xi'an Hani Tech provides broad integration between casting and downstream rolling processes, ideal for mini-steel plants. Dongguan Cheuk Kay serves niche sectors with centrifugal casting equipment, though its 60% on-time delivery rate suggests potential fulfillment risks. Buyers should prioritize suppliers with documented customization capabilities and verified delivery performance for mission-critical installations.

FAQs

How to verify continuous casting service supplier reliability?

Assess on-time delivery history, reorder rate, and response speed as proxies for operational stability. Request technical documentation including P&ID diagrams, load calculations, and cooling system specs. Conduct virtual audits to confirm in-house manufacturing versus outsourcing. Validate export experience through shipment records and client references in your target market.

What is the typical MOQ and pricing range?

Minimum order quantity is typically 1 set or 1 strand. Prices vary significantly by configuration: entry-level aluminum casting machines start at $12,000, while full slab casting lines exceed $400,000. Horizontal copper/brass systems are priced between $20,000 and $50,000 per unit.

Can suppliers customize casting machines for specific alloys?

Yes, most suppliers accommodate material-specific adaptations including mold design, temperature control, and feeding systems for steel, aluminum, copper, brass, and zinc. Custom tooling and PLC programming are commonly offered to match alloy thermal properties and output requirements.

Do continuous casting suppliers provide installation and training?

Leading suppliers include remote technical guidance as standard. On-site commissioning and operator training may be available at additional cost. Confirm scope of after-sales support—including spare parts availability and troubleshooting protocols—before contract finalization.

What are common lead times for continuous casting machines?

Standard configurations require 30–45 days for production and testing. Customized or multi-strand systems may take 60–90 days. Shipping via sea freight adds 20–40 days depending on destination region. Air freight is generally not feasible due to weight and dimensional constraints.