Continuous Production Definition

CN

CN

About continuous production definition

Where to Find Continuous Production Equipment Suppliers?

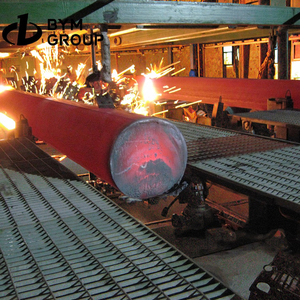

China remains the central hub for industrial continuous production systems, with key supplier clusters in Zhengzhou and coastal manufacturing zones offering specialized expertise in automated processing lines. These regions host vertically integrated facilities capable of engineering turnkey solutions for biomass carbonization, food processing, and material drying applications. The concentration of technical talent, component manufacturers, and export logistics networks enables competitive pricing and scalable production capacity.

Suppliers in these hubs typically operate multi-disciplinary production lines combining CNC machining, structural welding, and control system integration. This infrastructure supports rapid prototyping and batch manufacturing of continuous-process machinery such as rotary carbonization furnaces, mesh-belt dryers, and starch extraction lines. Buyers benefit from localized supply chains that reduce lead times by 20–30% compared to non-specialized manufacturers, with standard delivery windows ranging from 30 to 60 days depending on system complexity.

How to Choose Continuous Production Equipment Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure operational reliability and compliance:

Technical Compliance

Verify adherence to recognized quality standards such as ISO 9001 for design and manufacturing processes. For export markets, confirm compatibility with regional electrical codes (e.g., CE for Europe) and safety regulations. Request documentation on motor specifications, thermal efficiency ratings, and automation controls to validate performance claims.

Production Capability Audits

Assess core operational metrics during supplier screening:

- Minimum factory area exceeding 2,000m² to support full assembly lines

- In-house engineering teams for custom configuration and troubleshooting

- Integrated testing protocols for continuous operation validation (72-hour run tests recommended)

Cross-reference response times (target ≤4 hours) and on-time delivery records (preferably >95%) as indicators of operational maturity.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow until equipment passes destination inspections. Prioritize suppliers with documented after-sales service agreements, including remote diagnostics and spare parts availability. Conduct sample testing to verify throughput accuracy and energy consumption under real-world conditions before full-scale procurement.

What Are the Leading Continuous Production Equipment Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | Response Time | On-Time Delivery | Reorder Rate |

|---|---|---|---|---|---|---|

| DANUBE MACHINERY EQUIPMENT (SINGAPORE) PTE. LTD. | Drying Equipment, Waste Treatment Machinery, Carbonization Stoves | $17,000–48,000 | 1 set | ≤2h | Not specified | Not specified |

| DANUBE MACHINERY EQUIPMENT SINGAPORE PTE LTD | Briquette Machines, Carbonization Stoves, Waste Treatment Machinery | $16,000–128,000 | 1 set | ≤7h | Not specified | Not specified |

| DANUBE MACHINERY EQUIPMENT SINGAPORE PTE LTD | Carbonization Furnaces, Drying Equipment, Agricultural Machinery | $2,500–33,850 | 1–21,500 sets | ≤4h | Not specified | Not specified |

| Zhengzhou Anho Machinery Co., Ltd. | Fryers, Carbonization Furnaces, Packaging Machines | $5,000–25,000 | 1 set | ≤2h | 100% | <15% |

| Zhengzhou Jinghua Industry Co., Ltd. | Sweet Potato Starch Processing Lines, Flour Mills | $321,500 | 1 set | ≤11h | 100% | 33% |

Performance Analysis

DANUBE-affiliated entities offer broad product diversity across carbonization and drying technologies, with price points spanning entry-level to high-capacity systems. Zhengzhou-based suppliers demonstrate strong transactional reliability, with verified 100% on-time delivery rates and established reorder behavior indicating customer satisfaction. While multiple Danube-linked companies appear in the dataset, buyers should conduct due diligence to confirm organizational independence or consolidation. Suppliers with sub-4-hour response times generally exhibit higher engagement levels, a critical factor for post-installation support and technical coordination.

FAQs

How to verify continuous production equipment supplier reliability?

Validate certifications through issuing bodies and request factory audit reports covering design, welding procedures, and electrical safety. Analyze transaction history, focusing on delivery consistency and resolution of past disputes. Direct engagement via video inspection can confirm facility scale and workflow organization.

What is the typical lead time for customized continuous production lines?

Standard configurations ship within 30–45 days. Custom-engineered systems, particularly those integrating PLC controls or multi-stage processing, require 50–70 days for fabrication, testing, and packaging. Complex food-grade or high-temperature systems may extend timelines based on material sourcing.

Can suppliers accommodate OEM or private labeling requests?

Yes, most listed manufacturers support OEM branding, particularly in carbonization and food processing equipment. Minimum order requirements vary—typically one unit for large-scale machinery—but are negotiable based on long-term supply agreements.

Do suppliers provide installation and training services?

Many suppliers offer remote commissioning guidance and instructional documentation. On-site installation and operator training are often available at additional cost, particularly for systems exceeding $50,000. Confirm service coverage and travel expense terms prior to order placement.

What are common customization options for continuous production systems?

Buyers can specify feedstock type (wood chips, agricultural residue, starch-rich crops), hourly throughput (50–500 kg/h), power source (electric, gas, biomass-fired), and automation level (manual loading vs. fully integrated conveyors). Control panel interfaces may be adapted for local language and voltage requirements.