Continuous Production

Top sponsor listing

Top sponsor listing

CN

CN

1/9

1/9

About continuous production

Where to Find Continuous Production Equipment Suppliers?

China remains the central hub for continuous production machinery manufacturing, with key industrial clusters in Hebei and Henan provinces driving innovation and scale. Tangshan in Hebei Province hosts specialized metallurgy and rolling equipment manufacturers, leveraging proximity to major steel-producing centers to optimize supply chain integration. This strategic positioning enables reduced material logistics costs and faster component sourcing, particularly for heavy industrial systems such as continuous casting lines and metal processing equipment.

Meanwhile, Henan Province—home to Zhengzhou—has emerged as a center for advanced continuous process systems in sectors including oil refining, asphalt mixing, and carbonization. The region’s mature machinery ecosystem supports vertically integrated production, allowing suppliers to deliver turnkey solutions with shorter lead times. Buyers benefit from localized access to CNC machining, foundry operations, and automation integration services, typically achieving standard order fulfillment within 45–60 days. Cost efficiencies range from 20–35% compared to equivalent European or North American manufacturers due to lower labor and operational overheads.

How to Choose Continuous Production Equipment Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to recognized quality management standards such as ISO 9001. For export markets, confirm compliance with regional safety and environmental regulations (e.g., CE marking for EU imports). Request documentation on material traceability, weld integrity testing, and control system validation, especially for high-risk applications like high-temperature furnaces or pressurized refining units.

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Facility size exceeding 5,000m² for large-scale equipment fabrication

- In-house engineering teams capable of custom design and PLC-based automation integration

- Proven track record in delivering multi-unit installations or full production line setups

Cross-reference on-time delivery performance (target ≥97%) with response time metrics (ideally ≤4 hours) to assess operational responsiveness.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate financial risk. Prioritize suppliers offering third-party inspection rights prior to shipment. Conduct sample testing for critical performance parameters—for example, measuring temperature uniformity in carbonization furnaces or throughput accuracy in asphalt mixers—before placing bulk orders.

What Are the Best Continuous Production Equipment Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Product Range (USD) | Min. Order | Core Applications |

|---|---|---|---|---|---|---|

| Tangshan Fengrun District Runhao Rolling Machinery Co., Ltd. | Rolling Mills, Continuous Casting Lines, Industrial Furnaces | 100% | ≤4h | Not disclosed | Custom | Metal forming, billet processing |

| CAPIOUS ROADTECH PRIVATE LIMITED | Asphalt Mixers, Concrete Batching Plants | Not disclosed | ≤1h | $300,000–$450,000 | 1 unit | Road construction, paving operations |

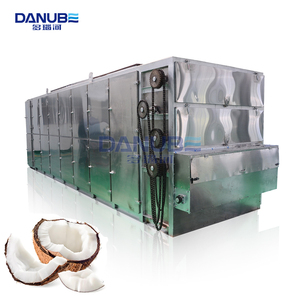

| DANUBE MACHINERY EQUIPMENT SINGAPORE PTE LTD | Carbonization Furnaces, Briquetting Systems | Not disclosed | ≤4h | $8,000–$28,000 | 1 set | Biochar production, waste-to-energy |

| Tangshan Bohai Metallurgy Intelligent Equipment Co., Ltd. | Continuous Casting Machines, Metal Processing Lines | 100% | ≤6h | $135,000–$413,000 | 1 strand | Steel casting, slab and billet production |

| Zhengzhou Dingsheng Machine Manufacturing Co. Ltd | Continuous Oil Refining Plants, Extraction Systems | Not disclosed | ≤12h | $290,000–$300,000 | 1 set | Edible oil refining, biodiesel processing |

Performance Analysis

Suppliers from Tangshan demonstrate strong reliability with verified 100% on-time delivery rates and deep expertise in metal processing systems. CAPIOUS ROADTECH stands out for rapid customer engagement (response ≤1 hour), making it suitable for time-sensitive procurement cycles. DANUBE MACHINERY offers cost-effective entry-level carbonization solutions, ideal for small to mid-scale biochar producers. Zhengzhou Dingsheng provides standardized oil refining systems with consistent pricing, facilitating budget predictability for edible oil processors. Buyers requiring full-line integration should prioritize suppliers with documented project execution experience and available facility tour options to validate engineering capabilities.

FAQs

What certifications should continuous production equipment suppliers have?

Essential certifications include ISO 9001 for quality management. Additional requirements depend on destination markets: CE for Europe, ASME for pressure vessels in North America, and local environmental compliance where applicable. Request test reports for structural components, electrical systems, and emission controls.

What is the typical lead time for continuous production machinery?

Standard configurations generally require 45–60 days for manufacturing and pre-shipment preparation. Custom-engineered systems may take 75–90 days, depending on complexity and component availability. Shipping via sea freight adds 20–40 days internationally.

Can suppliers accommodate customization requests?

Yes, most established manufacturers support technical modifications including capacity scaling, automation upgrades (PLC/SCADA), fuel type conversion, and integration with upstream/downstream equipment. Submit detailed specifications for process flow, input materials, and output targets to receive accurate proposals.

Do suppliers provide installation and commissioning support?

Many offer remote guidance as standard; on-site support is typically available at additional cost. Confirm whether training, spare parts kits, and maintenance manuals are included in the quotation. Some suppliers provide digital twin simulations for process validation prior to delivery.

What are common minimum order quantities (MOQs)?

MOQs vary by equipment type: single units for large systems (e.g., asphalt mixers, oil refineries), one-set minimums for modular machines (carbonization furnaces, briquetters). Negotiation is possible for repeat orders or bundled purchases across product lines.