Contract Cnc Programming Services

1/28

1/28

1/24

1/24

1/31

1/31

1/17

1/17

1/8

1/8

1/29

1/29

1/32

1/32

1/21

1/21

1/21

1/21

1/21

1/21

1/28

1/28

1/9

1/9

1/19

1/19

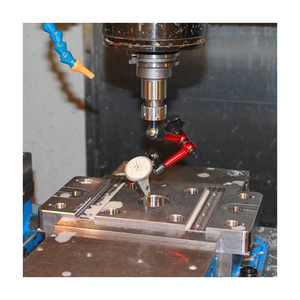

About contract cnc programming services

Where to Find Contract CNC Programming Services Suppliers?

China remains the central hub for outsourced CNC programming and precision machining services, with key industrial clusters in Guangdong, Fujian, and Zhejiang provinces. These regions host a high concentration of custom manufacturers equipped with advanced multi-axis CNC centers, CAD/CAM software suites, and integrated quality control systems. Shenzhen and Dongguan in Guangdong province specialize in high-mix, low-volume production for electronics, medical devices, and automation components, supported by mature supply chains for aluminum, stainless steel, brass, and engineering plastics.

Fujian-based suppliers, such as those in Xiamen, emphasize rapid prototyping and small-batch customization, leveraging agile workflows to deliver parts within 7–14 days. The region’s proximity to major ports enables efficient global shipping, while localized ecosystems reduce material procurement time by up to 30%. Buyers benefit from scalable production models—facilities support batch sizes from single prototypes to runs exceeding 10,000 units—with pricing advantages driven by competitive labor costs and vertical integration across design, programming, machining, and surface treatment processes.

How to Choose Contract CNC Programming Services Suppliers?

Selecting a reliable partner requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Engineering Capabilities

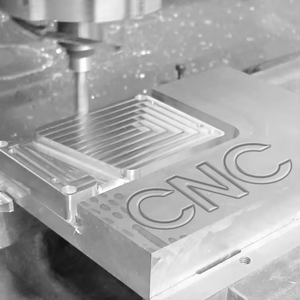

Confirm access to professional-grade CAM software (e.g., Mastercam, SolidWorks CAM, or Siemens NX) and experience in generating toolpaths for complex geometries, including 5-axis milling, Swiss turning, and micro-machining. Suppliers should demonstrate proficiency in GD&T application, tolerance management (±0.005 mm typical), and material-specific cutting strategies. For customized projects, verify that engineers can interpret 2D/3D drawings (STEP, DWG, IGES) and provide DFM feedback prior to production.

Production Infrastructure & Quality Assurance

Assess core capabilities through verifiable metrics:

- Minimum 10+ CNC machines (milling, turning, EDM) for production resilience

- In-house metrology equipment (CMM, optical comparators, micrometers) for first-article inspection

- Surface treatment options: anodizing, sandblasting, plating, passivation, laser engraving

Prioritize suppliers advertising on-time delivery rates above 95% and response times under 4 hours, indicators of operational discipline and customer service infrastructure.

Procurement & Risk Mitigation

Utilize milestone-based payment terms with partial escrow where available. Request sample batches before full-scale orders to validate dimensional accuracy and finish quality. Analyze reorder rates—suppliers with rates above 40% typically maintain consistent output and client satisfaction. For long-term contracts, confirm data confidentiality agreements are enforceable and digital files remain protected throughout the programming and manufacturing cycle.

What Are the Best Contract CNC Programming Services Suppliers?

| Company Name | Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Xiamen HYM Metal Products Co., Ltd. | Multispecialty Supplier | US $2,600,000+ | 100% | ≤4h | 50% | 1–1,000 pcs | $0.10–5.00 | Material, size, color, logo, packaging, graphic |

| Shenzhen SLD Precision Hardware Co., Ltd | Custom Manufacturer | US $420,000+ | 100% | ≤2h | 41% | 1 pc | $0.20–1.20 | Engraving, anodizing, laser cutting, sheet metal fabrication, material selection |

| Dongguan Shibo Hardware Products Co.,ltd. | Custom Manufacturer | US $170,000+ | 95% | ≤3h | 41% | 100 pcs | $0.40–1.50 | Material, size, logo, packaging, color, graphic |

| Core Hardware Electronics Co., Ltd | Multispecialty Supplier | US $220,000+ | 86% | ≤3h | <15% | 1–1,000 pcs | $0.10–6.99 | Design, drawing, material, size, logo, packaging |

| Dongguan Shipai Jingqi Hardware Products Factory | Manufacturer | US $20,000+ | 100% | ≤3h | 25% | 1 pc | $0.38–7.00 | Limited (primarily machining and casting services) |

Performance Analysis

Xiamen HYM leads in scalability and client retention, backed by a 50% reorder rate and robust online revenue performance, indicating strong market confidence. Shenzhen SLD distinguishes itself with sub-2-hour response times and broad customization depth, particularly in surface finishing and sheet metal processing—ideal for buyers requiring iterative design validation. Dongguan Shibo offers balanced cost-efficiency for mid-volume runs but enforces higher MOQs (100 pieces), making it less suitable for prototyping. Core Hardware Electronics provides wide price flexibility but exhibits lower reliability with an 86% on-time delivery rate and minimal reorder activity. Dongguan Shipai Jingqi, while maintaining perfect delivery records, has limited customization transparency and lower transaction volume, suggesting niche operational focus.

FAQs

What is the typical lead time for contract CNC programming and machining?

Standard lead times range from 7 to 15 days for prototype batches and 15 to 25 days for production volumes, depending on complexity and order size. Rush services may reduce timelines by 30–50% with expedited fees.

Do suppliers handle both programming and physical machining?

Yes, most integrated providers manage end-to-end workflows—from CNC program generation using CAM software to actual part production on owned machinery. Confirm whether G-code development is performed in-house, as this affects revision speed and IP control.

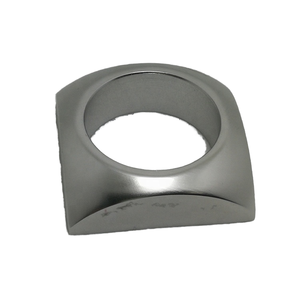

Can I request custom materials or finishes?

Top-tier suppliers support extensive material options (aluminum 6061/7075, stainless steel 303/316, brass, PEEK, Delrin) and finishes including hardcoat anodizing, electroplating, powder coating, and laser marking. Verify compatibility with functional requirements such as corrosion resistance or electrical insulation.

Is there a minimum order quantity (MOQ)?

MOQ varies significantly: some suppliers accept single-piece orders for prototypes, while others require 100–1,000 units for economic viability. Negotiate MOQ based on part complexity and setup costs.

How are intellectual property and design files protected?

Reputable manufacturers sign NDAs and restrict access to digital models and toolpaths. Ensure file transfer protocols use encrypted channels and confirm that programs are deleted or archived post-project unless otherwise agreed.