Controller Vibration Test

1/3

1/3

1/3

1/3

1/3

1/3

1/11

1/11

1/3

1/3

1/2

1/2

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/3

1/3

1/2

1/2

1/8

1/8

0

0

1/3

1/3

1/3

1/3

1/11

1/11

1/3

1/3

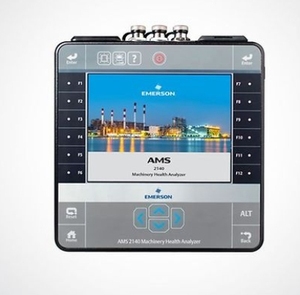

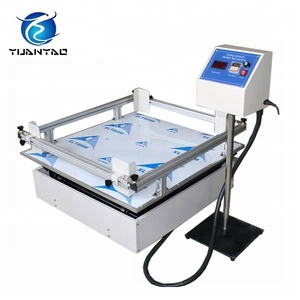

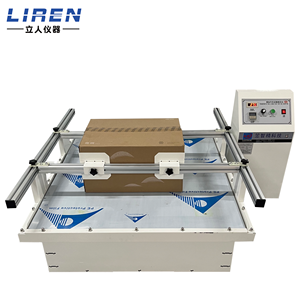

About controller vibration test

Where to Find Controller Vibration Test Suppliers?

China remains a central hub for vibration test equipment manufacturing, with key supplier clusters in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated production ecosystems specializing in precision testing instruments, supported by robust supply chains for sensors, actuators, and control systems. Dongguan and Yangzhou-based manufacturers leverage localized access to electronic components and CNC machining services, enabling cost efficiencies of 20–35% compared to Western counterparts.

The industrial infrastructure supports both standardized and engineered-to-order vibration controllers, with facilities equipped for dynamic signal processing, multi-axis simulation, and environmental integration (e.g., combined thermal-vibration testing). Proximity to R&D centers and metrology labs ensures adherence to international performance benchmarks. Buyers benefit from rapid prototyping capabilities, scalable batch production, and streamlined logistics—typical lead times range from 15 to 45 days depending on complexity and customization level.

How to Choose Controller Vibration Test Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Integration

Verify compatibility with industry standards such as IEC 60068-2-6, MIL-STD-810, and ISO 16750 for automotive or aerospace applications. Ensure controllers support required input/output channels, sampling rates (≥51.2 kS/s), and real-time closed-loop algorithms (random, sine, shock, HALT). Demand documentation for calibration traceability (NIST or equivalent) and software interoperability (e.g., LabVIEW, MATLAB).

Production Capability Assessment

Evaluate core competencies through the following criteria:

- Minimum 2 years of specialized experience in vibration test systems

- In-house design teams capable of firmware development and algorithm tuning

- Integration capabilities with shakers, amplifiers, and environmental chambers

Cross-reference product listings with delivery performance; prioritize suppliers maintaining ≥90% on-time shipment rates.

Transaction Risk Mitigation

Utilize secure payment mechanisms that align with order milestones, especially for high-value systems exceeding $20,000. Request factory inspection reports or video audits prior to shipment. Conduct functional testing upon receipt using known reference transducers to validate controller accuracy within ±1% amplitude tolerance.

What Are the Best Controller Vibration Test Suppliers?

| Company Name | Main Products | Product Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier | Customization |

|---|---|---|---|---|---|---|---|---|

| Yangzhou Zhenzhong Testing Technology Co., Ltd. | Vibration Signal Analyzers, Data Acquisition Controllers | $2,900–$8,420 | 1 piece/set | 100% | ≤4h | <15% | US $2,000+ | No data |

| Dongguan Haoen Automation Equipment Co., Ltd. | Electromagnetic Shakers, Multi-Axis Controllers | $599–$4,199 | 1 set | 100% | ≤1h | <15% | US $30,000+ | No data |

| Guangdong Jianqiao Testing Equipment Co., Ltd. | High-Frequency Tables, Dynamic Controllers | $3,000–$120,000 | 1–5 sets | 100% | ≤2h | - | - | No data |

| Xi'an Taimaoda Automation Equipment Co., Ltd. | Digital Level Controllers, OEM Modules | $423–$70,001 | 1–5 pieces/units | 90% | ≤1h | 18% | US $190,000+ | Color, material, logo, packaging |

| Wuxi Harris Environment Equipment Co., Ltd. | HALT Systems, Electrodynamic Shakers with Control Units | $6,800–$28,700 | 1 set | 100% | ≤2h | <15% | US $20,000+ | No data |

Performance Analysis

Dongguan Haoen stands out for responsiveness (≤1h average reply time) and competitive pricing, making it suitable for entry-level and mid-range vibration control needs. Xi’an Taimaoda offers extensive customization options and serves higher-tier clients, reflected in its significant online revenue ($190K+), though its 90% on-time delivery rate warrants closer monitoring. Wuxi Harris and Guangdong Jianqiao specialize in high-integration systems, including HALT and climatic-combined testing platforms, ideal for reliability engineering applications. Yangzhou Zhenzhong provides portable and field-calibration solutions at moderate price points, with consistent fulfillment records.

FAQs

How to verify controller vibration test supplier reliability?

Confirm technical documentation including frequency response curves, noise floor specifications, and phase coherence across channels. Validate company credentials via business licenses and export records. Assess after-sales support availability, particularly remote diagnostics and firmware updates.

What is the typical MOQ and lead time?

Standard controllers typically require a minimum order of 1 unit or set, with production lead times ranging from 10–20 days. For customized configurations involving software modifications or hardware integration, expect 30–50 days. Bulk orders (>10 units) may reduce per-unit costs by 10–20%.

Can vibration test controllers be customized?

Yes, select suppliers offer customization in enclosure materials, branding (logo, labeling), communication interfaces (Ethernet, USB, RS-485), and embedded software features. Confirm firmware modifiability and API access before procurement.

Do suppliers provide calibration certificates?

Reputable manufacturers issue出厂 calibration reports. For accredited verification, request optional NIST-traceable certification at an additional cost (typically +15–25%). Field recalibration services should be available through local partners or third-party labs.

How are high-value vibration test systems shipped and protected?

Systems are packed in reinforced wooden crates with anti-vibration padding and humidity control. Shipping terms vary—FOB terms place responsibility on the buyer for final transport and insurance. For sensitive electronics, opt for air freight with temperature and shock monitoring during transit.