Cost Of Aac Block Making Machine

Top sponsor listing

Top sponsor listing

1/9

1/9

1/19

1/19

1/19

1/19

CN

CN

1/12

1/12

1/16

1/16

1/49

1/49

CN

CN

CN

CN

1/33

1/33

CN

CN

1/18

1/18

CN

CN

1/24

1/24

About cost of aac block making machine

Where to Find AAC Block Making Machine Suppliers?

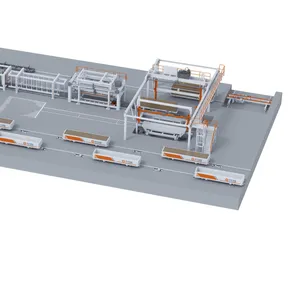

China remains the global epicenter for AAC (Autoclaved Aerated Concrete) block making machine manufacturing, with concentrated industrial hubs in Shandong and Henan provinces. These regions host vertically integrated production ecosystems that combine raw material processing, mechanical fabrication, and full-line assembly under one supply chain. Shandong’s machinery cluster, particularly around Linyi and Jining, specializes in large-scale, fully automated AAC plants leveraging proximity to steel and concrete equipment suppliers, reducing component procurement lead times by up to 25%. Henan, home to over half of China’s construction machinery exporters, offers competitive pricing due to high supplier density and optimized logistics via Zhengzhou’s central rail and air freight network.

Suppliers in these zones typically operate from facilities exceeding 5,000m², enabling parallel production of batching systems, molds, autoclaves, and conveyor integration. This infrastructure supports rapid deployment of turnkey solutions, with standard delivery windows ranging from 45 to 60 days for complete production lines. Buyers benefit from scalable output options—from compact semi-automatic units suitable for small enterprises to high-capacity fully automated systems producing 200–600 m³ of AAC blocks per day.

How to Choose AAC Block Making Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify that equipment adheres to international quality benchmarks such as ISO 9001 for quality management. For export markets in Europe or North America, confirm CE marking compliance to meet safety and environmental regulations. Request documentation on core system performance, including hydraulic pressure stability, vibration frequency control, curing cycle automation, and cutting accuracy (±1–2mm tolerance).

Production Capacity and Customization Capability

Assess supplier capacity through key indicators:

- Minimum factory area of 3,000m² for sustained production output

- In-house engineering teams capable of customizing mold configurations, block dimensions (standard: 600×200×250mm), and production line layout

- Integration of critical subsystems: mixing stations, pouring systems, steam curing chambers, and hydraulic demolding units

Cross-reference customization claims with actual product listings showing configurable parameters such as color, material mix ratio, brick shape, and packaging design.

Quality Assurance and Transaction Security

Prioritize suppliers with documented on-time delivery rates above 95% and response times under 3 hours. Utilize third-party inspection services pre-shipment to validate machine functionality, especially for complex systems involving autoclave integration and PLC-controlled operation. Where available, engage payment protection mechanisms to mitigate financial risk during international transactions.

What Are the Best AAC Block Making Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Linyi Aiwei International Trade Co., Ltd. | Shandong, CN | Brick Making Machinery, Concrete Mixers, Crushers | US $30,000+ | 100% | ≤1h | 16% | N/A | Color, capacity, mold design, hydraulic system, packaging |

| HENAN SUPERB MACHINERY CO., LTD. | Henan, CN | Brick Making Machinery, Diesel Generators, Pallets | US $220,000+ | 95% | ≤3h | <15% | $2,500–7,350 | Material, size, logo, label, graphic design |

| Shandong Weida Construction Machinery Co., Ltd. | Shandong, CN | Brick Making Machinery, Attachments, Crushers | US $240,000+ | 80% | ≤3h | 28% | $18,000–600,000 | Full line integration, mold size, motor type, silo configuration, automation level |

| Henan Yongyi Machinery Equipment Co., Ltd. | Henan, CN | Brick Making Machinery | - | 100% | ≤8h | <15% | $208–4,369 | Manual to semi-automatic models, compact designs for small businesses |

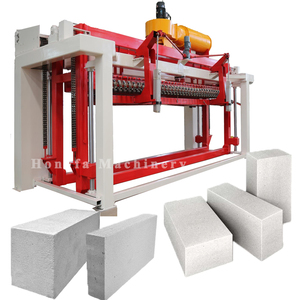

| Guangxi Hongfa Heavy Machinery Co., Ltd. | Guangxi, CN | Brick Making Machinery, ALC/AAC Panels | - | 100% | ≤2h | <15% | $499,972–1,000,000 | Block size, shaping capacity, material mix, video presentation, CAD drawings |

Performance Analysis

Shandong-based suppliers like Linyi Aiwei and Shandong Weida offer broad customization and robust production infrastructure, ideal for buyers seeking integrated AAC plant solutions. Shandong Weida stands out with a high reorder rate (28%) and extensive configurability across molds, conveyors, and automation levels, despite a lower on-time delivery rate (80%). Henan Superb Machinery provides mid-range automated systems at competitive prices ($4,650–7,350), backed by strong online sales volume and responsive communication. For budget-conscious buyers, Henan Yongyi offers entry-level manual and semi-automatic machines starting below $400, though limited service data increases procurement risk. At the premium end, Guangxi Hongfa caters to large-scale industrial clients with million-dollar turnkey installations, emphasizing precision engineering and project-specific design support.

FAQs

What is the typical cost range for an AAC block making machine?

Prices vary significantly based on automation level and capacity. Manual models start at $200–500/set, semi-automatic systems range from $2,500–8,000, fully automatic lines cost $30,000–80,000, while complete turnkey plants with autoclaves and silos can exceed $600,000.

What are common MOQ and lead time expectations?

Most suppliers require a minimum order of 1 set. Standard lead times range from 30 days for basic models to 60–90 days for customized, full-line installations. Expedited production may be available for urgent projects at additional cost.

Can suppliers customize block size and production capacity?

Yes, most established manufacturers offer adjustable mold sizes (e.g., 400–600mm length, 100–300mm thickness) and scalable output configurations from 50 m³/day to over 600 m³/day. Customization typically includes hydraulic system tuning, conveyor layout, and batching station integration.

Do suppliers provide installation and training support?

Many suppliers offer remote guidance via video manuals and technical documents. On-site installation and operator training are often available at extra cost, particularly for high-value orders. Confirm service terms before finalizing contracts.

How to verify machine quality before shipment?

Request test run videos demonstrating full operational cycles, including mixing, pouring, curing, and block ejection. Third-party inspection agencies can conduct pre-shipment audits to assess build quality, safety standards, and functional performance against agreed specifications.