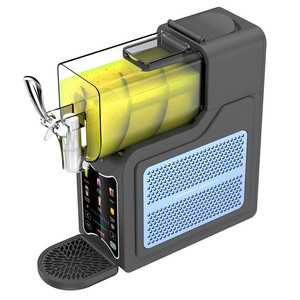

Crushed Ice And Ice Cube Maker

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About crushed ice and ice cube maker

Where to Find Crushed Ice and Ice Cube Maker Suppliers?

China remains the global hub for crushed ice and ice cube maker manufacturing, with key supplier clusters concentrated in Zhejiang and Henan provinces. Yuyao in Zhejiang hosts a dense network of appliance manufacturers specializing in compact refrigeration and ice-making equipment, supported by mature supply chains for compressors, evaporators, and food-grade plastics. This regional ecosystem enables rapid prototyping and cost-efficient production, particularly for countertop and portable units targeting residential and light commercial use.

In contrast, Zhengzhou in Henan province focuses on industrial-scale machinery, including block ice crushers and high-capacity electric ice chippers designed for seafood processing, catering, and hospitality sectors. These facilities typically integrate metal fabrication, motor assembly, and automated testing lines, allowing for robust production of heavy-duty models operating at 380V and above. The geographic concentration of component suppliers and logistics providers within 50km supports lead times averaging 20–35 days for standard orders, with localized sourcing reducing material costs by 15–25% compared to non-specialized regions.

How to Choose Crushed Ice and Ice Cube Maker Suppliers?

Procurement decisions should be guided by verified operational metrics and technical capabilities:

Quality Assurance Verification

Confirm adherence to international safety and performance standards such as CE, RoHS, and ISO 9001. For units intended for food service applications, ensure compliance with NSF or equivalent hygiene certifications. Request test reports covering electrical insulation, motor durability, and ice purity—particularly critical for machines using direct-contact grinding mechanisms.

Production Capacity Assessment

Evaluate infrastructure maturity through objective indicators:

- Minimum factory area exceeding 2,000m² for sustained volume output

- In-house engineering teams supporting customization (e.g., voltage adaptation, stainless steel housing)

- Integrated production lines covering injection molding, sheet metal processing, and final assembly

Cross-reference declared monthly capacity with historical on-time delivery rates (target ≥98%) to assess reliability under load.

Transaction Risk Mitigation

Utilize secure payment methods with milestone-based disbursement until post-arrival inspection is completed. Prioritize suppliers with documented dispute resolution procedures and transparent order tracking. Pre-shipment sample testing is essential—verify ice yield accuracy, noise levels (ideally ≤60 dB), and cycle consistency over 72 hours of continuous operation.

What Are the Best Crushed Ice and Ice Cube Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Yuyao Haohong Electrical Appliance Co., Ltd. | Zhejiang, CN | Ice Makers (130); Car Refrigerators (142) | US $180,000+ | 100% | ≤2h | <15% | Not specified | Moderate (multiple product listings) |

| Ningbo Younger Crops International Trade Co., Ltd. | Zhejiang, CN | Slush & Frozen Drink Machines | US $60,000+ | 100% | ≤10h | 20% | Color, material, size, logo, packaging | High (500 units) |

| Zhengzhou Yize Machinery Co., Ltd. | Henan, CN | Commercial Ice Crushers (5+ models) | US $450,000+ | 98% | ≤2h | 32% | Color, material, size, logo, packaging | Low (1 set minimum) |

| Yiwu Aikelansi Electrical Appliance Co., Ltd. | Zhejiang, CN | Countertop Crushed Ice Makers | US $70,000+ | 100% | ≤5h | <15% | Color, material, size, logo, packaging | Very low (2 pieces) |

| Zhengzhou Jieyuan Machinery Manufacturing Co., Ltd. | Henan, CN | Industrial Ice Crushers (5 models) | US $10,000+ | 100% | ≤2h | <15% | Not specified | Low (1 set minimum) |

Performance Analysis

Zhengzhou Yize Machinery leads in commercial segment revenue (US $450,000+) and customer retention (32% reorder rate), indicating strong satisfaction with its industrial ice-breaking solutions. Zhejiang-based suppliers demonstrate superior responsiveness, with three out of five achieving sub-5-hour average reply times and two maintaining 100% on-time delivery. Notably, Yiwu Aikelansi offers exceptional entry-level accessibility with MOQs as low as two units, ideal for small distributors or market testers. Ningbo Younger stands out for customization breadth, accommodating modifications across color, labeling, and structural materials—critical for private-label branding. Buyers requiring large-format machinery should prioritize Henan-based manufacturers with proven experience in 380V systems and bulk export logistics.

FAQs

How to verify crushed ice and ice cube maker supplier reliability?

Cross-check certification claims with issuing bodies and request factory audit reports. Analyze transaction history for consistent delivery performance and validate product conformity through independent lab testing or third-party inspection services like SGS or Bureau Veritas.

What is the typical sampling timeline?

Standard samples are produced within 7–14 days. Customized configurations involving modified molds or electrical specs require 20–30 days. Air freight adds 5–10 days for international delivery.

Can suppliers accommodate low-volume orders?

Yes, select suppliers like Yiwu Aikelansi accept MOQs as low as two pieces for standard models. However, unit pricing increases significantly below 100 units. Volume discounts typically apply at 500+ units.

Do manufacturers support OEM/ODM customization?

Multiple suppliers offer full OEM/ODM services, including custom housings, voltage adaptation (110V/220V), control panel design, and branded packaging. Minimum investment thresholds vary; expect tooling fees starting from US $1,500 for new mold development.

What are common payment and shipping terms?

Common terms include 30% T/T deposit with balance before shipment, or LC at sight. FOB Ningbo or FOB Shanghai are standard. Sea freight is optimal for full-container loads (FCL), while LCL or air shipping suits smaller consignments despite higher per-unit costs.