Ice Cube Maker And Crusher

About ice cube maker and crusher

Where to Find Ice Cube Maker and Crusher Suppliers?

China leads global production of ice cube maker and crusher equipment, with key manufacturing clusters in Zhejiang, Guangdong, and Shanghai. These regions host vertically integrated supply chains combining compressor fabrication, sheet metal processing, and refrigeration system assembly. Yongkang in Zhejiang specializes in compact electric ice crushers for commercial beverage service, while Guangzhou-based manufacturers focus on large-capacity ice-making systems with daily outputs ranging from 100kg to over 1,000kg. Shanghai suppliers integrate industrial-grade condensers and energy-efficient cooling methods into modular designs suitable for foodservice and hospitality sectors.

The concentration of component suppliers—compressors, evaporators, molds, and control panels—within 50km radii enables rapid prototyping and cost optimization. Localized logistics reduce lead times to 20–35 days for standard orders and allow flexible MOQs as low as one unit for select models. Buyers benefit from scalable production infrastructure capable of fulfilling both dropshipping volumes and bulk container shipments. Average cost savings range from 20–35% compared to equivalent Western-manufactured units due to lower labor and material procurement costs.

How to Choose Ice Cube Maker and Crusher Suppliers?

Evaluate potential partners using the following criteria:

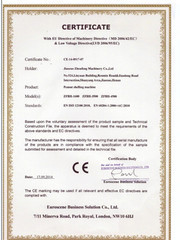

Technical Compliance & Certifications

Confirm compliance with international safety and performance standards such as CE, ETL, and RoHS. For North American and European markets, certification by recognized testing bodies is essential for customs clearance and operational legality. Request documentation validating electrical safety (e.g., 110V/220V compatibility), insulation integrity, and thermal efficiency under continuous operation cycles.

Production Capability Assessment

Analyze supplier infrastructure based on verifiable metrics:

- Minimum factory area supporting dedicated assembly lines for ice machines

- In-house R&D teams enabling customization of cooling method (air/water-cooled), cube size, and motor power

- Integration of compressor brands (e.g., Embraco, Secop) and stainless steel mold fabrication capabilities

Cross-reference online revenue indicators and reorder rates (>30% indicates strong customer retention) to assess market competitiveness and reliability.

Order Flexibility and Transaction Security

Prioritize suppliers offering MOQs aligned with business scale—from single-unit dropshipping to multi-unit commercial batches. Verify response time (≤4 hours recommended) and on-time delivery rate (target ≥99%). Utilize secure transaction mechanisms and inspect sample units for build quality, noise level during crushing cycle, and ice yield consistency before scaling procurement.

What Are the Best Ice Cube Maker and Crusher Suppliers?

| Company Name | Location | Online Revenue | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Product Range (Price Min) | Min Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Yongkang Tiange Electric Co., Ltd. | Zhejiang, CN | US $70,000+ | Ice Crushers & Shavers, Juicers, Blenders | 100% | ≤6h | <15% | $16.09–$28.19 | 1–2 pieces |

| Shanghai Tolcat Industrial Co., Ltd. | Shanghai, CN | US $300,000+ | Ice Machines, Packaging Equipment, Slaughtering Systems | 99% | ≤2h | 19% | $218–$4,800 | 1 piece/cubic meter |

| Guangzhou Desen Electrical Appliances Co., Ltd. | Guangdong, CN | US $200,000+ | Ice Machines, Sealing Machines | 100% | ≤3h | 41% | $490–$2,330 | 1–5 pieces |

| Guangzhou Anhe Catering Equipment Co., Ltd. | Guangdong, CN | US $880,000+ | Custom Ice Makers, Commercial Ice Machines | 100% | ≤4h | 31% | $230–$3,200 | 5 pieces |

| Shanghai Hengyue Refrigeration Equipment Co., Ltd. | Shanghai, CN | Not disclosed | Ice Machines, Refrigeration Equipment | 100% | ≤7h | Not available | $1,400–$3,000 | 1 piece |

Performance Analysis

Guangzhou Desen and Guangzhou Anhe demonstrate high customer retention (41% and 31% reorder rates respectively), indicating robust product performance and after-sales support. While Yongkang Tiange offers entry-level crushers at competitive prices ($16.09/unit), its sub-15% reorder rate suggests limited differentiation in durability or service. Shanghai Tolcat balances responsiveness (≤2h) with mid-tier reorder volume, making it suitable for time-sensitive sourcing. Guangzhou Anhe stands out for customization depth—including voltage, compressor type, and cube dimensions—supported by detailed technical parameters and mockup services. For large-scale deployments, Shanghai Hengyue provides high-output industrial machines with transparent pricing structures and proven scalability despite limited digital footprint.

FAQs

How to verify ice cube maker and crusher supplier reliability?

Cross-check certifications (CE, ETL) through official databases. Request factory audit reports or video tours confirming assembly line operations, quality control checkpoints, and inventory management. Analyze transaction history focusing on dispute resolution speed and return handling policies.

What is the typical sampling timeline?

Standard samples are dispatched within 7–14 days post-payment. Custom configurations involving modified molds or dual-voltage systems require 20–30 days for production and testing. Air freight adds 5–10 days for international delivery.

Can suppliers accommodate OEM/ODM requests?

Yes, multiple suppliers offer logo branding, packaging design, and functional modifications. Minimum order thresholds typically start at 50 units for logo imprinting and 100 units for structural changes such as axle length or storage capacity adjustments.

Do ice machine suppliers provide after-sales technical support?

Most established suppliers offer remote troubleshooting, spare parts supply, and controller diagnostics. High-revenue exporters include multilingual support teams and maintenance manuals compliant with IEC standards.

What are common payment and shipping terms?

Common payment methods include T/T, L/C, and platform-backed escrow. FOB terms are standard; CIF options are available for full-container loads. Sea freight is optimal for orders exceeding 5 units, reducing per-unit logistics costs by up to 40% versus air shipment.