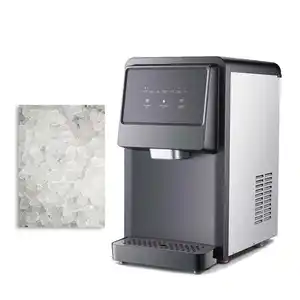

Crushed Ice Machine Maker

Top sponsor listing

Top sponsor listing

1/3

1/3

0

0

1/13

1/13

1/8

1/8

1/8

1/8

0

0

1/3

1/3

1/2

1/2

1/19

1/19

1/2

1/2

1/3

1/3

0

0

1/1

1/1

1/3

1/3

1/29

1/29

1/15

1/15

1/3

1/3

About crushed ice machine maker

Where to Find Crushed Ice Machine Maker Suppliers?

China remains the central hub for crushed ice machine manufacturing, with key production clusters in Guangdong and Zhejiang provinces driving innovation and export capacity. Shenzhen, Yongkang, and Guangzhou host vertically integrated facilities specializing in refrigeration systems, electric motors, and stainless steel fabrication—core components of commercial and residential crushed ice machines. These regions benefit from mature supply chains for compressors, condensers, and food-grade materials, reducing component lead times by 25–40% compared to offshore alternatives.

The industrial ecosystem supports rapid prototyping and scalable production, with many suppliers operating multi-disciplinary workshops capable of metal stamping, injection molding, and final assembly under one roof. This integration enables standard order fulfillment within 15–30 days, while bulk orders (10+ units) typically ship within 35 days. Buyers gain access to flexible MOQs—from single-unit dropshipping options to container-load productions—with cost advantages averaging 20–35% over Western manufacturers due to lower labor and logistics overheads.

How to Choose Crushed Ice Machine Maker Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure product reliability, compliance, and operational continuity.

Technical and Quality Compliance

Verify adherence to international safety and performance standards such as CE, ETL, or RoHS, particularly for equipment intended for North American or European markets. Confirm that critical components—including compressors, refrigerants (e.g., R600a), and electrical systems—meet regional regulatory requirements. Request test reports for noise levels, cooling efficiency, and energy consumption to validate performance claims.

Production and Customization Capability

Assess supplier infrastructure based on the following benchmarks:

- Facility size supporting continuous batch production (minimum 2,000m² recommended)

- In-house engineering teams enabling OEM/ODM services

- Customization options including voltage (110V/220V), plug type, color, branding, and refrigerant type

Prioritize suppliers offering detailed technical documentation and 3D drawings for customized models. Cross-reference online transaction volume with response time (target ≤6 hours) and on-time delivery rate (ideal ≥98%) to gauge operational efficiency.

Transaction Security and After-Sales Support

Utilize secure payment mechanisms such as escrow services to mitigate financial risk. Evaluate after-sales capabilities through warranty terms (typically 1–2 years), availability of spare parts, and responsiveness to service inquiries. Analyze reorder rates as a proxy for customer satisfaction—suppliers with reorder rates above 20% indicate strong post-purchase support and product durability.

What Are the Best Crushed Ice Machine Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization |

|---|---|---|---|---|---|---|---|---|

| SHENZHEN ICEUPS REFRIGERATION EQUIPMENT CO.,LTD | Shenzhen, CN | Ice Machines, Refrigeration Equipment | US $70,000+ | 100% | ≤7h | <15% | 15+ models | Limited |

| Yongkang Tiange Electric Co., Ltd. | Yongkang, CN | Ice Crushers, Juicers, Meat Grinders | US $70,000+ | 100% | ≤6h | 20% | 5 models | Basic (color, logo) |

| Guangzhou Bolt Electric Appliance Co., Ltd. | Guangzhou, CN | Commercial Ice Machines, Ice Cream Equipment | US $1,000+ | 100% | ≤6h | Not available | 5 models | Limited |

| Nanning Nanyuanfang Refrigeration Equipment Co., Ltd. | Nanning, CN | Nugget & Snowflake Ice Machines | US $700,000+ | 99% | ≤4h | 16% | 5 models | Extensive (cycle time, refrigerant, plug, packaging) |

| Guangzhou Foodsense Catering Equipment Co., Ltd. | Guangzhou, CN | Stainless Steel Ice Crushers, Commercial Equipment | US $300,000+ | 95% | ≤2h | 20% | 5 models | Full (material, size, logo, packaging) |

Performance Analysis

Nanning Nanyuanfang leads in customization depth and revenue scale, offering granular control over technical parameters and packaging, making it ideal for branded commercial deployments. Guangzhou Foodsense stands out for responsiveness (≤2h) and high reorder rate (20%), indicating robust customer retention and after-sales performance. SHENZHEN ICEUPS and Yongkang Tiange deliver consistent on-time shipment records (100%) and competitive entry-level pricing, suitable for small businesses or dropshipping operations. Guangzhou Bolt targets premium commercial clients with higher-capacity models but lacks reorder data, suggesting limited repeat buyer engagement. Prioritize suppliers with proven export experience, clear technical documentation, and verified customization workflows for mission-critical procurement.

FAQs

How to verify crushed ice machine maker reliability?

Cross-check certifications (CE, ETL, ISO) with official databases. Request factory audit reports or video tours to confirm production lines and quality control procedures. Analyze transaction history, focusing on dispute resolution outcomes and buyer feedback related to machine durability and cooling performance.

What is the typical MOQ and lead time?

MOQ ranges from 1 piece (dropshipping models) to 10+ units for custom batches. Standard lead time is 15–25 days post-payment, with express shipping options reducing delivery to 7–10 days via air freight. Sea freight is recommended for full-container orders to optimize logistics costs.

Can suppliers customize voltage and plug types?

Yes, most established suppliers offer dual-voltage configurations (110V/220V) and regional plug adaptations (US, EU, UK, AU). Full specifications must be confirmed during quotation to avoid compliance issues upon import.

Do crushed ice machine makers provide samples?

Sample availability depends on model and supplier policy. Some offer paid samples (priced at 1.5–2x unit cost) with credit toward future orders. Free samples are rare and typically reserved for high-volume buyers (50+ units).

What materials are commonly used in construction?

Commercial-grade units use stainless steel (SUS304) for contact surfaces, ABS plastic for housings, and copper/aluminum for condenser coils. Confirm material specifications to ensure food safety compliance and corrosion resistance in high-humidity environments.