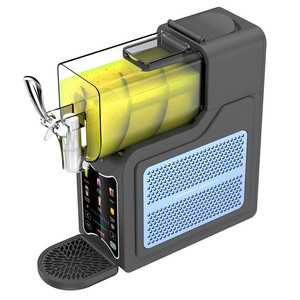

Crushed Ice Maker Machine For Home

CN

CN

About crushed ice maker machine for home

Where to Find Crushed Ice Maker Machine Suppliers for Home Use?

China remains the central hub for manufacturing compact household appliances, including crushed ice maker machines, with key production clusters in Zhejiang, Guangdong, and Ningbo. These regions host vertically integrated supply chains combining plastic injection molding, compressor assembly, and electronic control unit integration within tight geographic proximity. The concentration enables rapid prototyping, cost-efficient mass production, and streamlined export logistics—particularly via Ningbo and Shenzhen ports, which handle over 60% of China’s small appliance exports.

Suppliers in these zones benefit from mature ecosystems where component vendors (e.g., evaporators, condensers, food-grade augers) operate within 50km, reducing material lead times by up to 40%. This infrastructure supports flexible order fulfillment, with standard lead times averaging 25–35 days for bulk shipments. Buyers gain access to scalable production capacity, with many factories capable of monthly outputs exceeding 10,000 units. Cost advantages range from 20–35% compared to equivalent Western or Southeast Asian manufacturers due to lower labor costs and localized sourcing of core materials like ABS plastic and copper-wound motors.

How to Choose Crushed Ice Maker Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to international safety and performance standards. CE certification is essential for EU market access, while ETL or GS marks indicate compliance with North American or German electrical safety norms. Verify RoHS compliance for restricted substance control in consumer electronics. Request test reports on critical parameters: daily ice yield (typically 12–20kg), energy consumption (<0.8 kWh/24h), and noise levels (<45 dB). For products with water contact components, ensure use of food-grade materials compliant with NSF or FDA guidelines.

Production & Customization Capability

Assess scalability and customization readiness through the following indicators:

- Minimum factory area exceeding 3,000m² for stable volume output

- In-house design teams supporting OEM/ODM projects (e.g., UI customization, logo imprinting, color variants)

- Capacity for mold development and plastic extrusion processes

Cross-reference product listings with reorder rates and response times to gauge operational responsiveness. Prioritize suppliers with dedicated R&D staff and documented QC procedures, such as IPQC (In-Process Quality Control) and final 48-hour burn-in testing.

Transaction Risk Mitigation

Utilize secure payment frameworks such as escrow services to align payment release with delivery milestones. Evaluate supplier reliability using verifiable metrics: on-time delivery rate (>95%), response time (<12 hours), and reorder rate (indicative of customer satisfaction). Conduct sample validation to assess build quality, ice texture consistency (crushed vs. nugget), and cycle time accuracy before full-scale orders.

What Are the Top Crushed Ice Maker Machine Suppliers for Home Use?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Min. Order Flexibility | Customization Support |

|---|---|---|---|---|---|---|---|

| Yuyao Xinggu Electric Appliance Co., Ltd. | Compact Refrigerators (115), Ice Makers (18) | 100% | ≤9h | <15% | US $20,000+ | 1 piece (select models) | Limited |

| Yiwu Aikelansi Electrical Appliance Co., Ltd. | Ice Makers, Motorized Appliances | 96% | ≤4h | 17% | US $240,000+ | 2 pieces | Yes (color, size, logo, packaging) |

| Shenzhen Aurotech Technology Co., Ltd. | Portable Fans (92), Ice Makers (77) | 100% | ≤2h | 15% | US $130,000+ | 100 sets | Limited |

| Ningbo Goodtime Electric Appliance Co., Ltd. | Waffle Makers (67), Blenders (48) | 100% | ≤1h | 28% | US $10,000+ | 1 piece | No |

| Ningbo Hiking Electric Appliance Co., Ltd. | Electric Ice Crushers, Slush Machines | 100% | ≤4h | <15% | US $1,000,000+ | 1,000 pieces | Yes (material, size, logo, packaging) |

Performance Analysis

Yiwu Aikelansi and Ningbo Hiking demonstrate strong customization capabilities, making them ideal for branded or private-label deployments. Shenzhen Aurotech and Yuyao Xinggu offer reliable execution with 100% on-time delivery records, suitable for standardized procurement. Ningbo Goodtime stands out for low MOQ accessibility (1 piece), though its higher reorder rate (28%) may suggest post-sale service challenges. Ningbo Hiking leads in revenue scale (US $1M+), indicating high-volume export experience, but enforces large minimum orders (1,000 pcs), limiting suitability for trial runs. Buyers prioritizing fast communication should consider Shenzhen Aurotech (≤2h response) or Ningbo Goodtime (≤1h).

FAQs

What are typical MOQs for home crushed ice makers?

MOQs vary significantly: some suppliers offer single-unit sampling (e.g., $30/unit at 1 pc), while others require 100–1,000 units for competitive pricing. High-volume producers often set MOQs at 500+ units for fully assembled machines.

What is the average lead time for production and shipping?

Manufacturing lead time ranges from 20–35 days after deposit and sample approval. Air freight adds 5–10 days for urgent orders; sea freight takes 25–40 days depending on destination port congestion and customs processing.

Can suppliers provide CE or ETL-certified models?

Yes, multiple suppliers list CE, GS, or ETL-compliant units. Certification status must be confirmed per model number, and buyers should request copies of test reports issued by accredited labs.

Is customization available for retail branding?

Yes, select suppliers support OEM services including custom housing colors, branded nameplates, packaging design, and user interface labeling. Minimum volumes typically start at 500–1,000 units depending on complexity.

How to evaluate ice quality and machine durability?

Request physical or video samples demonstrating ice production cycles. Evaluate texture (should produce soft, chewable nugget or flake ice), noise level, and auto-shutoff functionality. Conduct accelerated life testing on compressors and augers—target >1,500 operational hours without failure for residential-grade units.