Cubelet Ice Maker

CN

CN

About cubelet ice maker

Where to Find Cubelet Ice Maker Suppliers?

China remains the global epicenter for cubelet ice maker manufacturing, with key production clusters in Guangdong and Henan provinces. These regions host vertically integrated supply chains encompassing compressor fabrication, stainless steel forming, and refrigeration system assembly. Guangdong, particularly around Guangzhou, specializes in commercial and industrial-grade units, leveraging proximity to component suppliers and export ports like Nansha, which reduces logistics lead times by 10–15% compared to inland regions.

The industrial ecosystem supports rapid prototyping and scalable production, with many manufacturers operating facilities exceeding 5,000m² and equipped with automated welding, CNC bending, and foam insulation injection lines. This infrastructure enables standard order fulfillment within 20–35 days. Buyers benefit from localized access to compressors (e.g., Embraco, Secop alternatives), evaporator molds, and food-grade stainless steel (SUS304), reducing material procurement cycles. Production capacities range from compact 25kg/day countertop models to high-output 1,000kg/day industrial systems, catering to diverse cooling demands across hospitality, medical, and food processing sectors.

How to Choose Cubelet Ice Maker Suppliers?

Selecting reliable suppliers requires a structured evaluation of technical, operational, and transactional parameters:

Technical & Quality Compliance

Verify adherence to international standards including CE, RoHS, and ISO 9001. For units destined for North American or European markets, confirm electrical compatibility (110V/60Hz or 220V/50Hz) and compliance with energy efficiency benchmarks. Request documentation on refrigerant type (commonly R404A, R410A, or eco-friendly R290) and third-party test reports for cooling cycle durability and noise levels (typically 40–50 dB).

Production Capability Assessment

Evaluate supplier infrastructure through verifiable metrics:

- Minimum factory area of 3,000m² for consistent batch output

- In-house mold design and refrigeration system integration

- Stainless steel fabrication capabilities (laser cutting, TIG welding)

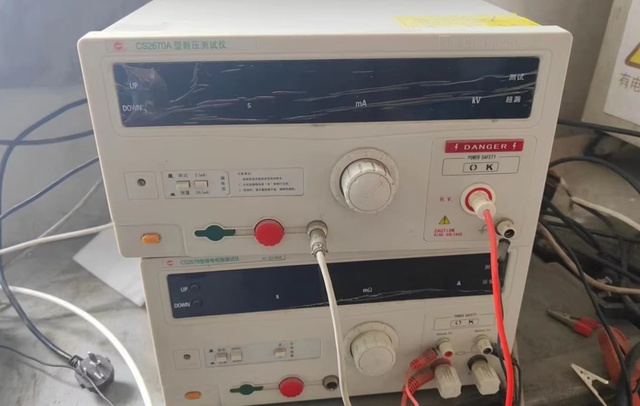

- Dedicated quality control stations for leak testing and performance validation

Cross-reference claimed output with online revenue data and on-time delivery rates (target ≥98%) to assess operational reliability.

Customization & Transaction Safeguards

Confirm availability of OEM/ODM services, including logo imprinting, color variation (white, silver, custom RAL), and capacity adjustments. Prioritize suppliers offering product mockups or 3D renderings within 72 hours of inquiry. Utilize secure payment mechanisms with milestone-based releases, ensuring final disbursement follows destination-side inspection. Pre-shipment sampling is recommended to validate ice clarity, cycle time, and bin hygiene.

What Are the Best Cubelet Ice Maker Suppliers?

| Company Name | Location | Online Revenue (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Luohe Ejin Machinery Co., Ltd. | Henan, CN | $140,000+ | 98% | ≤1h | <15% | Color, material, size, logo, packaging | 1 set | $250–1,500 |

| Guangzhou Anhe Catering Equipment Co., Ltd. | Guangdong, CN | $880,000+ | 100% | ≤4h | 31% | Capacity, compressor, condenser, controller, phase, dimensions | 1–5 pieces | $316–3,627 |

| Guangzhou Koller Refrigeration Equipment Co., Ltd. | Guangdong, CN | $120,000+ | 82% | ≤6h | 44% | Configuration, refrigerant, logo, safety frame, automatic control, mould size | 1 set/unit | $4,100–14,080 |

| Liaoyang Shenzhou Machinery Equipment Co., Ltd. | Liaoning, CN | $380,000+ | 100% | ≤2h | <15% | Color, material, size, logo, packaging | 1 set | $120–1,999 |

| Wenzhou Aism Electric Appliance Co., Ltd. | Zhejiang, CN | Not disclosed | 100% | ≤1h | Not available | Limited (product listings indicate focus on small appliances) | 1,000 pieces | $33.93–74.75 |

Performance Analysis

Guangzhou Anhe stands out with the highest online revenue ($880,000+) and a 31% reorder rate, indicating strong market acceptance and repeat business. Their broad customization scope—from compressor type to electrical phase—supports integration into diverse operational environments. Luohe Ejin and Liaoyang Shenzhou offer competitive entry-level pricing and low MOQs (1 set), ideal for small-scale buyers testing market demand. Guangzhou Koller targets high-end industrial clients with premium-priced units (up to $14,080), though its 82% on-time delivery rate presents a risk factor requiring closer monitoring. Wenzhou Aism’s low per-unit pricing suggests mass-production capability, but the 1,000-piece MOQ and limited product alignment imply niche applicability for private-label bulk orders rather than specialized ice-making solutions.

FAQs

How to verify cubelet ice maker supplier reliability?

Cross-check certifications with issuing bodies and request factory audit reports or video tours. Analyze customer reviews focusing on post-delivery support, ice yield consistency, and compressor longevity. Validate claims about refrigerant type and energy consumption through technical datasheets.

What is the typical lead time for bulk orders?

Standard lead times range from 20 to 35 days after deposit confirmation. Custom configurations may extend timelines by 10–15 days, especially if new molds or control systems are required. Air freight adds 5–7 days; sea freight takes 25–40 days depending on destination port.

Can suppliers accommodate OEM branding?

Yes, most established suppliers offer comprehensive OEM services, including custom logos, color finishes, user interface labels, and branded packaging. Minimum order thresholds typically start at 10–50 units, depending on complexity.

What are common MOQs for cubelet ice makers?

MOQs vary: industrial models often require 1 set, while compact or consumer-grade units may have MOQs of 5–100 pieces. Mass-market suppliers like Wenzhou Aism require 1,000-piece minimums, reflecting their production model.

How to negotiate better pricing and terms?

Leverage volume commitments and long-term contracts for discounts. Request FOB pricing clarity and explore container consolidation to reduce shipping costs. Prioritize suppliers with Trade Assurance or escrow-compatible payment terms to mitigate financial risk during negotiations.