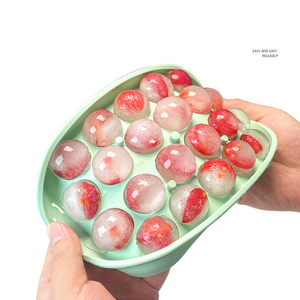

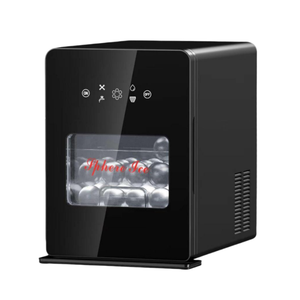

Sphere Cube Ice Maker

1/22

1/22

1/33

1/33

1/31

1/31

1/20

1/20

1/14

1/14

1/11

1/11

1/15

1/15

About sphere cube ice maker

Where to Find Sphere Cube Ice Maker Suppliers?

China leads global production of silicone and mechanical ice molding solutions, with key manufacturing clusters in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated supply chains specializing in food-grade silicone processing and compact appliance engineering. Guangzhou and Dongguan serve as hubs for high-volume silicone mold production, leveraging localized access to raw materials and injection molding facilities. Yuyao and Suzhou support advanced electromechanical ice-making equipment manufacturing, integrating refrigeration systems with precision mold design.

The industrial ecosystem enables rapid prototyping and scalable output, supported by mature logistics networks that ensure efficient export processing. Suppliers benefit from concentrated technical expertise in polymer science and small-appliance thermodynamics, allowing for cost-optimized production. Buyers can expect lead times of 15–30 days for standard orders, with bulk pricing reflecting 20–40% reductions compared to Western manufacturers due to lower labor and material costs. Customization capabilities—including shape, size, color, and branding—are widely available across tier-one suppliers.

How to Choose Sphere Cube Ice Maker Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on quality assurance, production capacity, and transaction reliability.

Material & Safety Compliance

Verify use of BPA-free, food-grade silicone compliant with FDA and EU Regulation (EC) No 1935/2004. For electrical ice-making units, confirm CE, RoHS, and UL certifications where applicable. Request test reports for material durability, including freeze-thaw cycle resistance (minimum 1,000 cycles) and dimensional stability under temperatures ranging from -40°C to 230°C.

Production Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum monthly output capacity exceeding 100,000 units for molds or 5,000 units for electric machines

- In-house mold design and CNC tooling capabilities

- Dedicated quality control stations with batch traceability systems

Cross-reference online revenue data and on-time delivery rates—prioritize suppliers with ≥90% fulfillment performance and response times under 3 hours.

Transaction Security & Sampling Protocols

Utilize secure payment mechanisms such as escrow services for initial transactions. Require physical or digital samples before mass production, particularly for custom designs. Assess sample lead times (typically 7–14 days) and clarity of communication during prototyping. Favor suppliers offering customization options in color, logo printing, packaging, and grid configuration (e.g., 6-cavity sphere, cube hybrid molds).

What Are the Best Sphere Cube Ice Maker Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) | Customization |

|---|---|---|---|---|---|---|---|---|

| Suzhou Snowboy Im & Export Trade Co., Ltd. | Silicone Ice Molds, Baking Tools | US $40,000+ | 100% | ≤3h | <15% | 10 pcs | $0.20–$2.25 | Limited |

| Dongguan Shouhongyu Silicone Products Co., Ltd. | Silicone Ice Molds, Kids Dining | US $30,000+ | 46% | ≤8h | 27% | 2 pcs | $1.25–$1.33 | Standard Shapes |

| Guangzhou Raybin Homewares Co., Ltd. | Reusable Ice Ball Makers, Plastic & Silicone | US $610,000+ | 91% | ≤2h | 29% | 50–100 pcs | $0.25–$1.96 | Full (color, size, logo, packaging) |

| Yuyao Haohong Electrical Appliance Co., Ltd. | Countertop Ice Machines, Sphere Ice Makers | US $180,000+ | 100% | ≤2h | <15% | 100 pcs | $79.90–$139.90 | OEM/ODM Supported |

| Hong Kong Bereal Supply Chain Management Co., Limited | Portable Ice Makers, Freestanding Units | US $20,000+ | 100% | ≤2h | 19% | 5–100 pcs | $42–$195 | Select Models |

Performance Analysis

Guangzhou Raybin stands out with the highest reported online revenue and robust customization infrastructure, supporting full brand integration at competitive unit prices. Despite a moderate reorder rate, its sub-2-hour response time and 91% on-time delivery reflect strong operational efficiency. Yuyao Haohong and Hong Kong Bereal specialize in motorized sphere ice machines, targeting commercial and premium household segments with countertop models producing crystal-clear ice balls. Suzhou Snowboy offers the lowest entry MOQs and pricing, ideal for niche retail testing. Dongguan Shouhongyu’s low MOQ is advantageous but offset by a significantly lower on-time delivery rate (46%), indicating potential fulfillment risks.

FAQs

What materials are used in sphere cube ice makers?

Primary materials include food-grade platinum-cured silicone for molds and ABS/PP plastics for structural components. Electric models incorporate stainless steel evaporators and compressors. All materials must be BPA-free and compliant with food contact regulations in target markets.

What is the typical MOQ for ice molds and machines?

Silicone molds typically require 50–100 pieces for customized orders, though some suppliers accept as low as 10 pieces. Electric ice-making machines have higher MOQs, generally starting at 100 units per model due to assembly complexity and certification requirements.

How long does it take to receive a sample?

Sample lead times range from 5 to 14 days depending on customization level. Standard silicone molds ship within one week; engineered ice machines may require up to 25 days for prototype assembly and testing.

Can suppliers provide private labeling and packaging design?

Yes, most established suppliers offer OEM services including custom logos, color Pantone matching, retail-ready packaging, and user manual localization. Guangzhou Raybin and Yuyao Haohong explicitly list packaging and graphic customization among their service offerings.

Are there differences between manual molds and automatic ice ball machines?

Manual silicone molds require freezing water in standard freezers and produce translucent ice. Automatic machines use directional freezing technology to create dense, clear ice spheres suitable for premium bars and hospitality. These units operate independently but require water supply, power source, and periodic descaling maintenance.