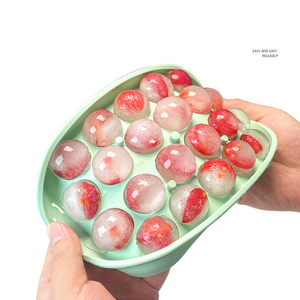

Ice Cube Maker Sphere

About ice cube maker sphere

Where to Find Ice Cube Maker Sphere Suppliers?

China remains the global epicenter for ice cube maker sphere production, with key manufacturing clusters concentrated in Guangdong and Shandong provinces. Guangdong—particularly Dongguan and Shenzhen—hosts specialized silicone and plastic mold manufacturers leveraging advanced injection molding and vulcanization technologies. These regions benefit from mature polymer supply chains and proximity to Hong Kong and Shenzhen ports, enabling efficient export logistics. Shandong, known for industrial refrigeration equipment, contributes high-capacity commercial sphere ice machines, integrating metal fabrication and refrigeration engineering expertise.

The regional specialization enables a dual-tier supplier ecosystem: Guangdong dominates consumer-grade reusable molds (silicone/plastic), offering low MOQs and rapid customization, while Shandong focuses on heavy-duty electric ice-making systems with daily outputs ranging from 200kg to 3 tons. This geographic bifurcation allows buyers to align sourcing strategies with application needs—household, barware, or commercial hospitality—while benefiting from localized economies of scale, reduced component procurement cycles, and streamlined quality control oversight.

How to Choose Ice Cube Maker Sphere Suppliers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

Material & Product Compliance

Verify that consumer-facing molds are manufactured from food-grade, BPA-free silicone or PP plastic compliant with FDA and EU Regulation (EC) No 1935/2004. For commercial electric units, confirm CE, CB, or ETL certification for electrical safety and performance. Request test reports for material composition and thermal stability (operating range: -40°C to 230°C for silicone).

Production Capacity & Scalability

Assess infrastructure indicators relevant to order volume:

- Minimum factory area of 1,000m² for mold/tooling specialists

- In-house mold design and CNC prototyping capabilities

- Monthly output capacity exceeding 100,000 units for reusable molds

Cross-reference claimed capabilities with verified on-time delivery rates (target ≥90%) and reorder rates to assess operational reliability.

Customization & Transaction Security

Prioritize suppliers offering full OEM/ODM support—including logo embossing, color matching (Pantone), packaging design, and tray configuration—backed by digital proofing. Utilize secure transaction platforms with escrow services to mitigate risk. Conduct pre-shipment inspections for batch consistency, particularly for transparent ice molds where clarity and dimensional accuracy are critical.

What Are the Best Ice Cube Maker Sphere Suppliers?

| Company Name | Location | Main Products | Min. Order Quantity | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Raybin Homewares Co., Ltd. | Guangdong, CN | Reusable plastic/silicone molds | 50–100 pieces | $0.25–1.96 | 92% | ≤2h | 28% | $600,000+ |

| Shandong Qianrui Machinery Technology Co., Ltd. | Shandong, CN | Commercial electric sphere ice makers | 1 set | $500–7,600 | 100% | ≤1h | <15% | $9,000+ |

| Dongguan Shouhongyu Silicone Products Co., Ltd. | Guangdong, CN | Silicone rose/diamond molds | 2 pieces | $1.25–1.33 | 44% | ≤8h | 27% | $30,000+ |

| Shenzhen Zoho Silicone Products Co., Ltd. | Guangdong, CN | Clear large ice ball molds | 20 packs | $0.99–12.30 | 100% | ≤8h | 25% | $600+ |

| Shenzhen Mebol Hardware Co., Ltd. | Guangdong, CN | 3D diamond/rose molds | 3,000 pieces | $0.60–2.80 | 100% | ≤2h | 100% | $70+ |

Performance Analysis

Guangzhou Raybin and Shenzhen Mebol exemplify high-volume mold producers with robust customization options and competitive pricing, ideal for retail and promotional markets. Mebol stands out with a 100% reorder rate, indicating strong customer satisfaction despite a higher MOQ. Shandong Qianrui is the sole provider of fully automated commercial sphere ice machines, catering to hotels and bars requiring consistent output, though its lower reorder rate suggests potential gaps in after-sales service. Dongguan Shouhongyu offers ultra-low MOQs (as low as 2 pieces), suitable for sampling and niche e-commerce, but its 44% on-time delivery rate presents fulfillment risks. Buyers prioritizing reliability should favor suppliers with ≤2h response times and 100% on-time delivery records, particularly for time-sensitive campaigns.

FAQs

What materials are used in ice cube maker spheres?

Consumer-grade molds are typically made from food-safe silicone (platinum-cured) or polypropylene (PP). Commercial machines use stainless steel evaporators and ABS housing. Confirm BPA-free and FDA compliance for all food-contact materials.

What is the typical lead time for bulk orders?

Standard mold orders (500–5,000 units) require 15–25 days production plus 7–14 days shipping. Custom tooling adds 10–15 days. Electric ice machine lead times range from 30–45 days due to complex assembly and testing.

Can suppliers provide custom molds?

Yes, most Guangdong-based mold suppliers offer full OEM services, including custom cavity shapes (e.g., logos, geometric patterns), colorants, and packaging. Minimum order for new molds typically starts at 1,000–3,000 units.

Do suppliers offer samples?

Sample availability is common. Many suppliers provide 1–2 free samples for evaluation, especially if followed by an order. For customized prototypes, expect fees covering 30–50% of tooling cost, refundable against future production runs.

What are the packaging and labeling options?

Suppliers offer retail-ready solutions: blister cards, gift boxes, multilingual labels, and branded hangtags. Bulk industrial orders typically ship in plain polybags with master cartons. Custom artwork integration is standard upon request.