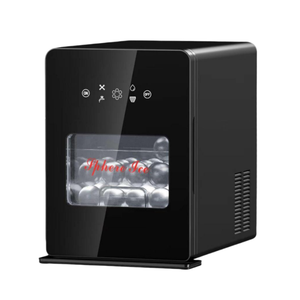

Spherical Ice Cube Maker

About spherical ice cube maker

Where to Find Spherical Ice Cube Maker Suppliers?

China remains the dominant manufacturing hub for spherical ice cube makers, with key production clusters concentrated in Guangdong and Henan provinces. Guangzhou-based suppliers leverage proximity to port infrastructure and mature kitchen equipment ecosystems, enabling streamlined export logistics and rapid prototyping capabilities. These regions host vertically integrated supply chains encompassing mold fabrication, stainless steel processing, and electronic control assembly, reducing component lead times by 20–30% compared to offshore alternatives.

The industrial clusters support both high-volume OEM production and low-MOQ customized orders, catering to commercial bar equipment distributors and consumer appliance brands. Facilities typically operate automated injection molding lines and CNC machining centers, achieving monthly outputs ranging from 5,000 to 20,000 units depending on model complexity. Integration with local material suppliers ensures consistent access to food-grade ABS plastic, silica gel, and 304 stainless steel—key materials for hygienic ice formation and durability.

How to Choose Spherical Ice Cube Maker Suppliers?

Procurement decisions should be guided by objective evaluation of technical, operational, and transactional performance indicators:

Quality Assurance & Compliance

Prioritize suppliers offering CE, ETL, or RoHS certifications, particularly for North American and European markets. Verify compliance documentation for electrical components and food-contact materials. For commercial-grade models, confirm adherence to IPX7 waterproofing standards and UL-listed power systems to ensure safe operation in wet environments.

Production Capacity & Customization

Assess scalability through facility metrics and order fulfillment history:

- Minimum factory area exceeding 2,000m² for stable batch production

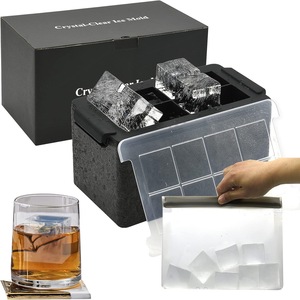

- In-house tooling and mold-making capabilities for custom sphere diameters (typically 45–60mm)

- Support for color, logo, packaging, and UI customization (LCD touchscreen variants available)

- On-time delivery rate ≥98% as an indicator of production planning reliability

Cross-reference stated capacities with verified online revenue data and product listing volume to assess operational scale.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services for initial orders. Favor suppliers with documented quality control processes, including pre-shipment inspections and functional testing of heating/cooling cycles. Request sample units to evaluate ice formation time (typically 15–30 minutes per cycle), noise levels (<45 dB), and structural integrity before bulk procurement.

What Are the Best Spherical Ice Cube Maker Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Whalfly Tek Co., Ltd. | Ice Makers (469) | US $9,000+ | 100% | ≤1h | <15% | Not specified | 1 piece | $126–159.99 |

| Guangzhou Itop Kitchen Equipment Co., Ltd. | Multiproduct Supplier | US $980,000+ | 98% | ≤4h | <15% | Color, size, logo, packaging, label, graphic | 10 pieces | $127–683 |

| Jiaozuo Forward Machine Co., Ltd. | Commercial Ice Equipment | US $190,000+ | 99% | ≤4h | <15% | Logo, graphic | 1 set | $204–1,710 |

| Guangzhou Chashimi Kitchen Equipment Co., Ltd. | Bar & Kitchen Tools | US $160,000+ | 94% | ≤5h | <15% | Color, material, size, logo, packaging, label, graphic | 1 piece | $150–365 |

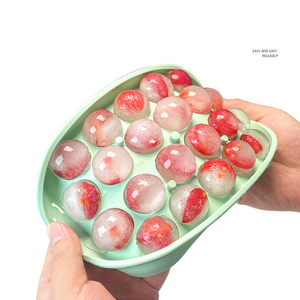

| Yiwu Lvye E-Commerce Firm | Silicone Molds (Manual) | US $250,000+ | 99% | ≤10h | 17% | Color, size, logo, mold design, packaging, silica gel | 50 sets | $0.83–2.50 |

Performance Analysis

Guangzhou-based suppliers dominate in customization breadth and export readiness, with Itop and Chashimi offering comprehensive OEM/ODM support for branded deployments. Whalfly Tek stands out for responsiveness (≤1h) and 100% on-time delivery, making it suitable for urgent small-batch sourcing. Jiaozuo Forward targets commercial clients with higher-power, stainless steel units priced above $250, reflecting industrial build quality. Yiwu Lvye specializes in low-cost silicone molds for manual use, serving budget-conscious retailers with MOQs starting at 50 sets. Buyers seeking premium electric models should prioritize suppliers with ETL/CE certification and in-house R&D teams capable of supporting firmware and UI adjustments.

FAQs

What is the typical lead time for spherical ice cube maker orders?

Standard orders require 15–25 days for production, with an additional 7–14 days for international shipping via air or sea freight. Customized models may extend lead times to 30–40 days depending on tooling requirements.

Can suppliers provide product certifications?

Yes, reputable manufacturers supply CE, ETL, and RoHS compliance documents upon request. Verification through third-party testing reports is recommended for regulatory clearance in target markets.

Do spherical ice makers require special maintenance?

Electric models with auto-cleaning functions reduce scaling risks. Suppliers recommend descaling every 1–2 months using food-safe solutions, especially in high-hardness water regions. Stainless steel and ABS plastic housings facilitate wipe-down sanitation.

Are free samples available?

Sample policies vary: some suppliers offer paid samples refundable against future orders, while others charge full production cost. Expect sample fees between $100–300 for electric units; silicone molds range from $10–50.

What customization options are commonly supported?

Suppliers routinely accommodate branding (logo imprinting), color variation (ABS housing), packaging redesign, and UI localization. Advanced partners offer PCB modifications, touchscreen interfaces, and custom mold cavities for non-standard sphere sizes.