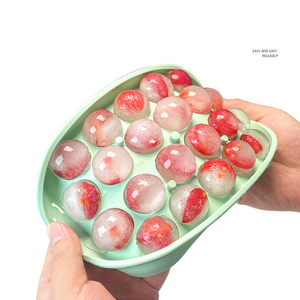

Circular Ice Cube Maker

1/29

1/29

1/21

1/21

1/20

1/20

1/35

1/35

1/14

1/14

1/4

1/4

1/24

1/24

1/22

1/22

1/11

1/11

1/25

1/25

1/27

1/27

About circular ice cube maker

Where to Find Circular Ice Cube Maker Suppliers?

China remains the global epicenter for circular ice cube maker production, with key manufacturing clusters in Fujian, Zhejiang, and Henan provinces. These regions host vertically integrated supply chains specializing in food-grade silicone, plastic molding, and small kitchenware fabrication. Xiamen and Yiwu serve as primary export hubs due to their proximity to major ports and established e-commerce logistics networks, enabling efficient order fulfillment for international buyers.

The sector is dominated by mid-sized manufacturers combining injection molding capabilities with rapid prototyping for customized molds. Facilities typically operate automated production lines capable of producing 50,000–200,000 units monthly, depending on material complexity and cavity design. Common materials include BPA-free polypropylene, food-grade silicone, and ABS plastic, processed via high-pressure injection or compression molding techniques. This infrastructure supports both mass-market trays and premium 3D logo molds with tight tolerances.

How to Choose Circular Ice Cube Maker Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure product quality, compliance, and supply chain reliability:

Material & Safety Compliance

Verify that suppliers use FDA-approved, BPA-free materials compliant with EU Regulation (EC) No 1935/2004 for food contact surfaces. Request RoHS and LFGB test reports where applicable, especially for silicone-based molds. Ensure packaging adheres to environmental standards such as REACH and Proposition 65 for U.S. market entry.

Production and Customization Capacity

Assess technical capabilities through the following benchmarks:

- Minimum 3,000m² factory area with dedicated molding and assembly zones

- In-house mold design and CNC tooling teams for custom cavity development

- Capacity to support color, shape, size, and branding customization (logo imprinting, graphic labeling)

- Ability to produce multi-cavity designs (6–33 cavities per tray) and specialty forms (sphere, lattice, column)

Cross-reference online transaction volume and reorder rates—suppliers with consistent annual revenues above US $100,000 and response times under 5 hours demonstrate operational stability.

Order Flexibility and Transaction Security

Prioritize suppliers offering low minimum order quantities (MOQs) for sampling—some provide MOQs as low as 5–36 pieces for initial testing. For bulk procurement, standard MOQs range from 500–1,000 units. Confirm integration with secure payment escrow systems and evaluate on-time delivery performance (target ≥97%). Conduct pre-shipment inspections using third-party auditors when ordering containers.

What Are the Best Circular Ice Cube Maker Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Xiamen Theone Household Products Co., Ltd. | Fujian, CN | US $10,000+ | 98% | ≤2h | <15% | Color, material, shape, size, logo, packaging, label, graphic | 500 pcs | $0.75–0.85 |

| Shangqiu Bingya Refrigeration Equipment Co., Ltd. | Henan, CN | US $30,000+ | 100% | ≤2h | <15% | N/A (Commercial equipment focus) | 1 set | $338–2,310 |

| Hangzhou Yuanji Gift Co., Ltd. | Zhejiang, CN | US $310,000+ | 97% | ≤7h | <15% | Color, material, size, logo, packaging, label, graphic | 36 pcs | $0.46–5.20 |

| Yiwu Lvye E-Commerce Firm | Zhejiang, CN | US $260,000+ | 100% | ≤10h | 17% | Color, material, size, logo, mold, packaging, label, silica gel, graphic | 20 sets | $0.57–3.76 |

| Dongguan GMI Electronic Co., Ltd. | Guangdong, CN | US $140,000+ | 92% | ≤5h | <15% | Color, material, size, logo, mold, weight, packaging, label, graphic | 100 pcs | $0.58–1.90 |

Performance Analysis

Hangzhou Yuanji leads in revenue scale and offers competitive pricing starting at $0.46 per unit with flexible MOQs, making it ideal for entry-level importers. Yiwu Lvye stands out for extensive customization depth, including silica gel formulation and mold engineering, suitable for branded private-label development. Xiamen Theone delivers consistent responsiveness and tight price control, beneficial for stable recurring orders. Shangqiu Bingya caters to commercial refrigeration applications with high-capacity cylindrical ice machines, targeting hospitality and beverage industries. Dongguan GMI provides mid-range pricing with strong material and mold customization but slightly lower on-time performance. Buyers seeking innovation in form factor (e.g., ball, lattice, press-type) should prioritize suppliers with documented mold design experience and sample turnaround within 7–10 days.

FAQs

How to verify circular ice cube maker supplier reliability?

Validate compliance documentation for food safety standards (FDA, LFGB). Review supplier transaction history, focusing on verified on-time delivery rates and response efficiency. Request customer references or third-party audit summaries if scaling beyond trial orders.

What is the typical sampling timeline?

Standard samples are produced within 5–10 days. Custom molds requiring CNC tooling take 12–18 days. Air shipping adds 7–10 business days internationally. Some suppliers offer digital mockups before physical sampling.

Can suppliers ship globally?

Yes, most manufacturers support FOB, CIF, and DAP shipping terms. They coordinate with freight forwarders for LCL or full-container loads, particularly from Ningbo, Shanghai, and Xiamen ports. Confirm incoterms and destination customs requirements during quotation.

Do suppliers offer free samples?

Policies vary. Many waive fees for qualified buyers committing to future bulk orders. Otherwise, expect to pay 50–100% of sample cost, which may be credited upon order confirmation.

How to initiate customization requests?

Submit detailed specifications: desired dimensions, cavity count, material type (silicone vs. plastic), color Pantone codes, logo placement, and packaging format. Reputable suppliers respond with CAD drawings or 3D renderings within 48–72 hours for approval prior to tooling.