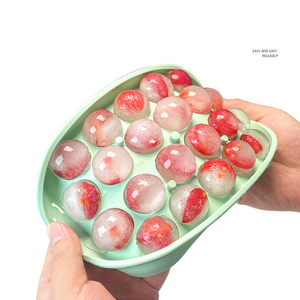

Circle Ice Cube Maker

About circle ice cube maker

Where to Find Circle Ice Cube Maker Suppliers?

China leads global production of specialized ice-making tools, with key manufacturing clusters in Guangdong and Jiangsu provinces. These regions host vertically integrated supply chains for plastic injection molding, silicone fabrication, and food-grade material processing—core competencies for circle ice cube makers. Guangzhou-based suppliers leverage proximity to polymer raw material hubs, reducing component sourcing lead times by 15–20% compared to offshore alternatives. Suzhou’s industrial zone offers advanced mold design capabilities, supporting rapid prototyping for spherical cavity trays.

The concentration of ancillary services—including packaging, logistics, and compliance testing—enables streamlined operations. Factories typically maintain in-house tooling departments and automated assembly lines, allowing batch production scaling within 7–14 days of order confirmation. Buyers benefit from localized ecosystems where material suppliers, quality inspectors, and freight forwarders operate within close geographic proximity, ensuring shorter cycle times and cost efficiency. Average production costs are 25–35% lower than equivalent Western-made products due to optimized labor and energy inputs.

How to Choose Circle Ice Cube Maker Suppliers?

Implement structured evaluation criteria to ensure supplier reliability and product conformity:

Material & Safety Compliance

Confirm use of BPA-free plastics or food-grade silicone compliant with FDA and EU Regulation (EC) No 1935/2004. Request test reports for migration of substances under cold conditions. For export markets, verify RoHS and LFGB certifications where applicable. Avoid suppliers unable to provide traceable material data sheets.

Production Capacity Verification

Assess operational scale through objective metrics:

- Minimum monthly output capacity exceeding 100,000 units for standard tray models

- In-house mold development capability (minimum 3-axis CNC machining)

- Automated quality inspection systems (e.g., visual defect detection)

Cross-reference declared output with online transaction volume; suppliers reporting over US $200,000 in annual revenue demonstrate consistent fulfillment ability.

Customization & Transaction Security

Prioritize vendors offering configurable options in color, logo imprinting, packaging format, and cavity size. Validate customization feasibility through prototype samples. Utilize secure payment mechanisms such as escrow services, particularly for first-time transactions. Analyze reorder rates (target >25%) and on-time delivery performance (ideal ≥95%) as indicators of operational stability.

What Are the Best Circle Ice Cube Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | MOQ Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Raybin Homewares Co., Ltd. | Guangdong, CN | Ice trays, plastic drinkware | US $590,000+ | 92% | 27% | ≤2h | 50–100 pcs | $0.25–2.13 |

| GUIXING INDUSTRIAL CO., LIMITED | Guangdong, CN | Silicone molds, storage bags | US $20,000+ | 100% | <15% | ≤2h | 10–100 pcs | $0.89–1.99 |

| Guangzhou Dubang Electrical Appliances Co., Ltd. | Guangdong, CN | Commercial ice machines | US $30,000+ | 83% | 66% | ≤11h | 1 set | $710–1,393 |

| Suzhou Innovation Packaging Materials Co., Ltd. | Jiangsu, CN | Sphere trays, novelty molds | US $10,000+ | 75% | <15% | ≤4h | 300–1,000 pcs | $0.16–2.55 |

| Guangzhou Rayshine Technology Co., Ltd. | Guangdong, CN | Portable ice ball makers | US $230,000+ | 98% | 17% | ≤3h | 50–100 pcs | $0.24–2.20 |

Performance Analysis

Guangzhou-based manufacturers dominate responsiveness and scalability, with three suppliers achieving sub-3-hour average reply times. Guangzhou Raybin and Rayshine exhibit strong commercial traction, evidenced by high online revenue and repeat order volumes. Raybin stands out for broad customization scope across color, material, and labeling—critical for private-label buyers. GUIXING achieves perfect on-time delivery but shows low reorder frequency, suggesting limited post-sale engagement. Suzhou Innovation offers the lowest per-unit pricing ($0.16 at MOQ 1,000), making it suitable for budget-conscious bulk procurement despite moderate delivery reliability. Dubang specializes in large-scale commercial equipment, positioning it outside consumer-grade tray production but relevant for industrial spherical ice solutions.

FAQs

How to verify material safety for circle ice cube makers?

Request compliance documentation for FDA 21 CFR §177.1520 (for polyolefins) or EU 10/2011 (plastic materials in contact with food). Third-party lab reports from SGS or TÜV confirming BPA-free status and heavy metal absence under cold extraction tests are essential for regulatory clearance.

What is the typical lead time for bulk orders?

Standard production cycles range from 15 to 25 days after sample approval. Orders requiring custom molds may extend lead times by 10–14 days. Air freight adds 5–7 days internationally; sea shipping requires 25–35 days depending on destination port.

Can suppliers accommodate private labeling and packaging design?

Yes, most established suppliers support OEM/ODM services including logo embossing, custom colorants, retail-ready blister packs, and multilingual instruction inserts. Minimum order thresholds typically start at 1,000 units for full branding customization.

Do manufacturers provide free samples?

Sample availability varies. Many suppliers offer paid samples (priced at 1.5x unit cost) refundable against future orders above 500 pieces. True free samples are rare and generally limited to stock items without customization.

What are common MOQs and pricing structures?

Typical MOQs range from 50 to 1,000 units depending on complexity. Simple silicone molds start at $0.16/unit (1,000 pcs), while multi-cavity BPA-free plastic trays average $0.25–$0.80/unit. Higher prices reflect material upgrades, intricate designs, or packaging requirements.