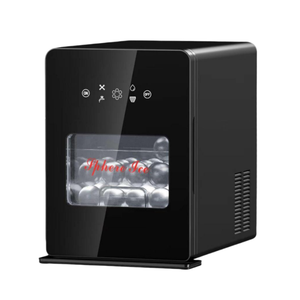

Spherical Ice Cube Machine

About spherical ice cube machine

Where to Find Spherical Ice Cube Machine Suppliers?

China remains the dominant manufacturing hub for spherical ice cube machines, with key suppliers concentrated in Zhejiang and Guangdong provinces. These regions host vertically integrated supply chains encompassing mold fabrication, injection molding, and final assembly, enabling cost efficiencies of 20–35% compared to Western or Southeast Asian producers. Yuyao in Zhejiang and Foshan in Guangdong are recognized industrial clusters for small-scale commercial and household ice-making appliances, supported by mature ecosystems of component vendors and logistics networks.

Suppliers in these zones benefit from proximity to raw material sources—primarily food-grade ABS and stainless steel—and access to high-efficiency production lines capable of producing 10,000–30,000 units monthly per facility. The clustering effect reduces lead times, with standard orders typically fulfilled within 25–40 days. Buyers gain flexibility in order volume, ranging from low MOQs for prototyping to bulk shipments exceeding 500 units, supported by established export channels to North America, Europe, and Asia-Pacific markets.

How to Choose Spherical Ice Cube Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Management Systems

Verify adherence to international standards such as CE, RoHS, and ISO 9001. While not all suppliers explicitly list certifications in public data, prioritize those demonstrating compliance through product documentation. Electrical components should meet IEC safety standards, particularly for household-use models operating on 110V–240V inputs.

Production and Customization Capacity

Assess supplier infrastructure based on the following indicators:

- Minimum factory area of 3,000m² for sustained volume output

- In-house tooling and mold development capabilities

- Support for OEM/ODM services, including logo printing and packaging customization

Cross-reference product listings with reorder rates below 20% and on-time delivery performance above 99% to identify reliable partners.

Order Flexibility and Risk Mitigation

Confirm MOQ terms aligned with procurement scale: some suppliers offer single-unit sampling (e.g., 1 piece), while others require 100–500 units. Use secure payment mechanisms such as escrow services and request sample testing before full production. Evaluate response time (ideally ≤2 hours) and language proficiency to ensure smooth communication during order execution.

What Are the Best Spherical Ice Cube Machine Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) | Customization |

|---|---|---|---|---|---|---|---|---|

| Yuyao Haohong Electrical Appliance Co., Ltd. | Ice Makers (124) | US $170,000+ | 100% | ≤2h | <15% | 1–500 pcs | $79.90–139.90 | No |

| Whalfly Tek Co., Ltd. | Ice Makers (470) | US $9,000+ | 100% | ≤1h | <15% | 1–100 pcs | $99–159.99 | No |

| Hong Kong Bereal Supply Chain Management Co., Limited | Ice Makers (30) | US $20,000+ | 100% | ≤2h | 20% | 5–100 pcs | $42–195 | No |

| Jiaozuo Forward Machine Co., Ltd. | Commercial Ice Equipment | US $190,000+ | 99% | ≤4h | <15% | 1 set | $204–1,710 | Yes (logo) |

| Foshan Diaking Industry Co., Ltd. | Ice Makers (349) | US $500+ | 100% | ≤5h | <15% | 300 pcs | $128–150 | No |

Performance Analysis

Yuyao Haohong and Whalfly Tek offer competitive pricing and low MOQs, making them suitable for entry-level buyers and market testing. Whalfly Tek stands out with a sub-1-hour response time and extensive product range, indicating strong customer service capacity. Jiaozuo Forward Machine targets commercial clients with higher-end, customizable systems starting at $268 per set, backed by robust revenue and branding options. Foshan Diaking provides mid-range pricing but enforces a 300-piece minimum, favoring bulk purchasers. Hong Kong Bereal offers the lowest unit price ($42) at 5 pieces MOQ, presenting value potential for small distributors despite limited customization.

FAQs

What materials are used in spherical ice cube machines?

Most units use food-grade ABS plastic for housing and internal molds, with select commercial models incorporating stainless steel evaporators for durability and thermal efficiency. Seals and water-contact components must comply with NSF or equivalent standards for safe operation.

What is the typical production lead time?

Standard orders take 25–40 days from confirmation, depending on customization and order volume. Sample units can be dispatched within 7–15 days. Expedited production may reduce timelines by 5–10 days at additional cost.

Can suppliers provide machine customization?

Limited customization is available. Jiaozuo Forward Machine supports logo integration, while most other suppliers offer fixed configurations. For ODM projects, engage manufacturers with dedicated R&D teams and mold-making facilities to develop proprietary designs.

Do spherical ice makers require special maintenance?

Yes. Regular descaling using citric acid solutions is required to prevent mineral buildup, especially in hard water areas. Commercial units should undergo quarterly inspections of compressors and condensers to maintain optimal ice clarity and production rate.

Are spare parts and technical support available?

Supplier policies vary. High-revenue exporters like Yuyao Haohong and Jiaozuo Forward typically provide one-year warranties and basic technical guidance. Buyers should confirm spare part availability (e.g., pumps, trays, control boards) and consider stocking critical components for uninterrupted operation.