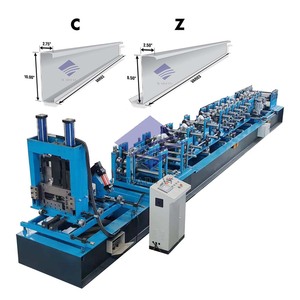

Custom C Purlin Making Machine

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

About custom c purlin making machine

Where to Find Custom C Purlin Making Machine Suppliers?

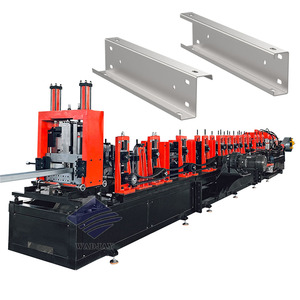

China remains the global epicenter for roll forming machinery production, with key manufacturing clusters concentrated in Hebei and Shandong provinces. These regions host vertically integrated industrial ecosystems specializing in cold roll-forming technology, enabling efficient fabrication of structural steel profiles such as C purlins. The proximity of raw material suppliers, CNC processing centers, and logistics networks allows manufacturers to maintain lean production cycles and competitive pricing.

Suppliers in Cangzhou and Shijiazhuang dominate this niche, leveraging decades of metallurgical engineering expertise and access to high-grade galvanized steel coils. Facilities typically operate under ISO 9001 quality frameworks and utilize automated production lines capable of producing machines that support variable profile dimensions (80–300 mm depth) and material thicknesses (0.6–4.0 mm). Buyers benefit from localized supply chains that reduce component lead times by up to 30% compared to offshore alternatives, with standard machine delivery windows averaging 30–50 days post-deposit.

How to Choose Custom C Purlin Making Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

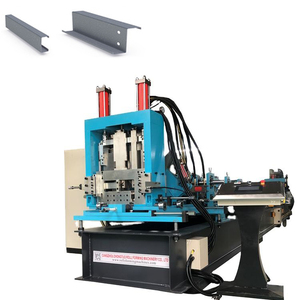

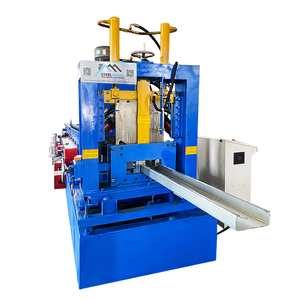

Confirm adherence to international safety and performance standards, including CE marking for electrical control systems and mechanical design compliance with EN 12193 or equivalent. Request documentation on motor specifications (typically 7.5–15 kW), PLC brands (e.g., Delta, Siemens), and roller shaft hardness (HRC 58–62 after heat treatment). Machines should support customization in material feed width, punch configurations, and cutting mechanisms (fly knife vs. hydraulic shear).

Production Capability Audits

Assess infrastructure maturity through verifiable metrics:

- Minimum factory area exceeding 3,000m² to ensure dedicated assembly zones

- In-house machining capabilities for rollers, shafts, and dies to maintain dimensional accuracy

- Engineering teams capable of generating CAD drawings and simulation models for customized line layouts

Cross-reference online revenue data and reorder rates as proxies for market trust—suppliers with >22% reorder rates demonstrate consistent output quality.

Transaction Safeguards

Utilize secure payment terms such as irrevocable LC at sight or platform-backed trade assurance programs. Require pre-shipment inspections via third-party agencies like SGS or Bureau Veritas. Prioritize suppliers offering video walkthroughs of completed machines before dispatch, particularly when procuring fully automatic lines with integrated stackers and PLC touchscreens.

What Are the Best Custom C Purlin Making Machine Suppliers?

| Company Name | Location | Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Scope | Sample Lead Time |

|---|---|---|---|---|---|---|---|---|

| Cangzhou Zhongtuo International Trade Co., Ltd. | Cangzhou, CN | Custom Manufacturer | US $4,700,000+ | 100% | ≤2h | 37% | Color, material size, logo, packaging, graphic, workshop layout | 35–45 days |

| Shijiazhuang Yingyee Machinery Co., Ltd. | Shijiazhuang, CN | Multispecialty Supplier | US $2,800,000+ | 100% | ≤1h | 100% | Color, material size, logo, packaging, label, graphic | 30–40 days |

| Tianjin Ironstar Industry Co., Ltd. | Tianjin, CN | Multispecialty Supplier | US $1,700,000+ | 100% | ≤1h | 50% | Color, material size, logo, packaging, label, graphic | 35–50 days |

| Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd. | Cangzhou, CN | Custom Manufacturer | US $990,000+ | 92% | ≤2h | 100% | Color, material size, simulation design, profile, electric control, logo, packaging, cold roll process | 40–50 days |

| Jinan Steelmama International Trade Co., Ltd. | Jinan, CN | Multispecialty Supplier | US $400,000+ | 100% | ≤2h | 22% | Color, material size, logo, packaging, label, graphic | 30–45 days |

Performance Analysis

Cangzhou-based manufacturers exhibit strong customization depth, particularly in workshop integration and cold roll process optimization. Shijiazhuang Yingyee stands out with a 100% reorder rate and sub-hour response time, indicating high client retention and service agility. While Cangzhou Forward reports a slightly lower on-time delivery rate (92%), its comprehensive customization options—including full electrical system design—make it suitable for complex turnkey installations. Tianjin Ironstar demonstrates mid-tier scalability with balanced responsiveness and repeat business volume. Price points vary significantly: entry-level semi-automatic models start around $11,800, while advanced multi-functional lines with auto-change systems exceed $36,000. For large-scale procurement, prioritize suppliers with proven export experience to target markets and documented CE certifications.

FAQs

How to verify custom C purlin making machine supplier reliability?

Validate certifications (ISO 9001, CE) through official registries and request factory audit reports. Analyze transaction history indicators such as on-time delivery rate (>95% recommended), response speed, and verified customer reviews focusing on after-sales technical support and spare parts availability.

What is the average sampling timeline for customized machines?

Prototype or sample machine production typically takes 30–50 days depending on complexity. Basic configurations require approximately 30 days, while fully automated lines with PLC integration and custom die sets may extend to 50 days. Shipping via sea freight adds 15–30 days internationally.

Can suppliers ship globally?

Yes, established manufacturers have export licenses and partner with freight forwarders to manage FOB, CIF, or DDP shipments. Confirm compliance with destination country regulations regarding voltage specifications (380V/50Hz standard) and machinery safety directives.

Do suppliers offer free samples or trial runs?

Full machine samples are not provided free due to high production costs. However, many suppliers offer live video testing of completed units or allow remote commissioning verification. Some may waive pilot batch fees for orders exceeding two units.

How to initiate customization requests?

Submit detailed technical requirements including desired purlin dimensions (web/flange/leg size), material yield strength (Q235/Q355), coil width range, and automation level (manual feeding vs. full-auto servo). Reputable suppliers will respond with layout diagrams, 3D models, and process flowcharts within 72 hours.