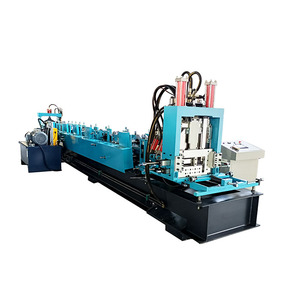

Custom C Purlin Roll Forming Machine

Top sponsor listing

Top sponsor listing

1/27

1/27

1/11

1/11

1/11

1/11

1/19

1/19

1/24

1/24

CN

CN

1/17

1/17

1/9

1/9

1/19

1/19

1/13

1/13

1/17

1/17

1/20

1/20

About custom c purlin roll forming machine

Where to Find Custom C Purlin Roll Forming Machine Suppliers?

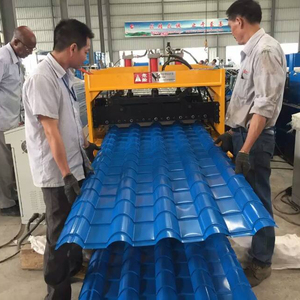

China remains the dominant hub for custom C purlin roll forming machine manufacturing, with key industrial clusters concentrated in Hebei, Zhejiang, and Henan provinces. These regions host vertically integrated supply chains that support rapid prototyping and large-scale production of cold roll forming equipment. Cangzhou in Hebei Province has emerged as a specialized center for steel framing machinery, benefiting from proximity to major steel mills and logistics networks that reduce raw material procurement times by 15–20% compared to offshore competitors.

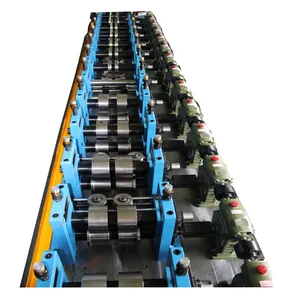

The ecosystem includes suppliers offering full automation systems, PLC-controlled forming lines, and modular designs for CZ purlin profiles. Buyers benefit from localized access to hydraulic decoilers, slitting units, precision roller stations, and automatic stackers—components typically sourced within 50 km of main assembly plants. This integration enables lead times averaging 30–45 days for customized machines, with scalability for batch orders exceeding 20 units. Cost advantages range from 25–35% over European or North American manufacturers due to lower labor costs and efficient component sourcing.

How to Choose Custom C Purlin Roll Forming Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

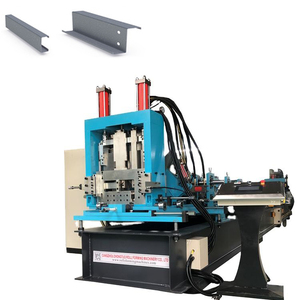

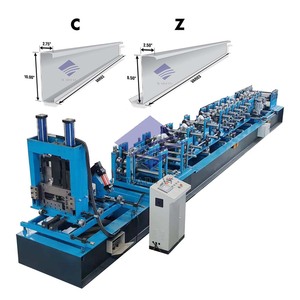

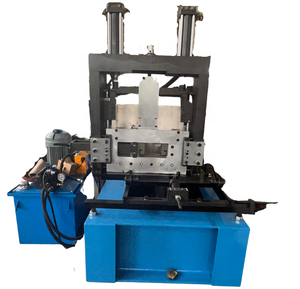

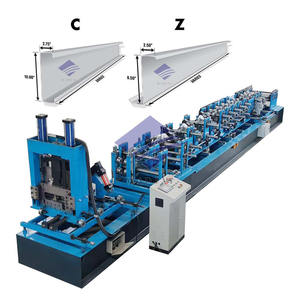

Confirm expertise in cold roll bending technology and profile precision engineering. Machines should support coil thicknesses from 1.5mm to 4mm and accommodate variable widths (up to 1,250mm) with CNC-adjustable roller stations. Demand design drawings and PLC control system specifications before order confirmation. Suppliers with in-house R&D teams are better equipped to handle non-standard configurations such as triple-layer door frames or hybrid C/U/Z profile changovers.

Production Infrastructure Assessment

Evaluate the following benchmarks:

- Facility size supporting dedicated assembly lines (minimum 3,000m² recommended)

- In-house capabilities in welding, machining, and hydraulic system integration

- Availability of customization services including logo printing, color coating, and packaging labeling

Cross-reference supplier claims with on-time delivery performance (target ≥98%) and response time metrics (≤2 hours preferred).

Quality & Transaction Assurance

Prioritize suppliers adhering to ISO 9001 quality management standards. While CE certification is not universally present, it should be required for compliance in EU markets. Utilize secure payment mechanisms such as escrow services and request sample testing protocols. Validate machine durability through test runs on-site or via video inspection, focusing on dimensional accuracy, coil alignment, and cutting precision.

What Are the Best Custom C Purlin Roll Forming Machine Suppliers?

| Company Name | Type | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Cangzhou Zhongtuo International Trade Co., Ltd. | Custom Manufacturer | Steel Frame & Purlin Machines, Tile Making Machinery | Material size, roller stations, coil width, PLC design, hydraulic decoiler, graphic holes, packaging label | 100% | ≤2h | 37% | US $4,700,000+ |

| Hangzhou Zhongyuan Machinery Factory | Manufacturer | Steel Frame & Purlin Machines, Tile Making Machinery | Limited customization; manual vs. fully automatic models available | 100% | ≤2h | - | - |

| Jinan Steelmama International Trade Co., Ltd. | Multispecialty Supplier | U/M/CZ Purlin Machines, Steel Framing Equipment | Color, material size, logo, packaging, graphic elements | 100% | ≤1h | 22% | US $440,000+ |

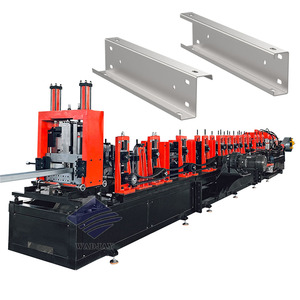

| Henan Wadjay Machinery Co., Ltd. | Multispecialty Supplier | C-Z Profile Purlin Machines, Industrial Forming Systems | Profiles, drawing-based design, color, size, packaging, logo | 100% | ≤2h | 21% | US $360,000+ |

| Botou Shitong Cold Roll Forming Machinery Manufacturing Co., Ltd. | Manufacturer | C/U/Z Purlin Machines, Coil Slitting & Straightening Equipment | Adjustable forming widths, multiple thickness options, automated stacking | 100% | ≤4h | - | US $20,000+ |

Performance Analysis

Cangzhou Zhongtuo leads in scale and customization depth, supported by high online revenue (over US$4.7M) and a 37% reorder rate—indicating strong customer retention. Its broad product range and extensive technical offerings make it suitable for complex, high-volume projects. Jinan Steelmama stands out for responsiveness (≤1h average reply time) and competitive pricing, with entry-level machines starting at $15,000. Hangzhou Zhongyuan offers premium automation solutions priced up to $107,000, targeting buyers needing fast-size-change and full-auto operation. Botou Shitong provides cost-effective semi-automatic options but lags in digital engagement with slower response cycles. Suppliers based in Hebei and Shandong demonstrate superior infrastructure maturity, while Henan-based vendors offer agile, mid-tier alternatives ideal for budget-conscious procurement.

FAQs

How to verify a supplier’s technical capability for custom purlin machines?

Request detailed technical documentation including machine layout diagrams, PLC interface samples, and roller station configurations. Conduct virtual factory audits to observe CNC machining centers and assembly lines. Confirm experience with required materials (e.g., galvanized steel coils) and output speeds (typically 10–20 meters per minute).

What is the typical MOQ and lead time?

Minimum order quantity is generally 1 set. Lead times vary from 30 to 45 days depending on automation level and customization complexity. Simple manual models may ship within 25 days, while fully automated, PLC-integrated systems require additional calibration time.

Can suppliers customize machine specifications?

Yes, most suppliers listed offer customization in coil width (up to 1,250mm), thickness (1.5–4mm), roller count (12–20 stations), and automation features (hydraulic decoiler, auto-cutter, stacker). Design modifications such as special profile shapes or multi-material compatibility must be validated through engineering drawings prior to production.

Do suppliers provide after-sales support and installation guidance?

Reputable suppliers offer remote troubleshooting, operator training via video, and technical manuals in English. Some provide on-site commissioning services at additional cost. Verify warranty terms (typically 12 months) and spare parts availability before finalizing contracts.

Are there cost differences between manual and automatic models?

Significant differences exist: manual changeover models start around $8,000–$18,000, while fully automatic, fast-change C/Z purlin lines range from $85,000 to $107,000. Automation reduces labor input and increases throughput but requires higher upfront investment and more complex maintenance.