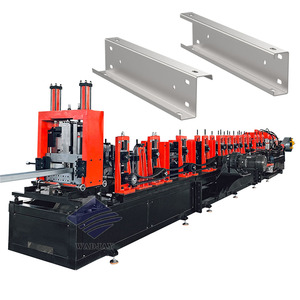

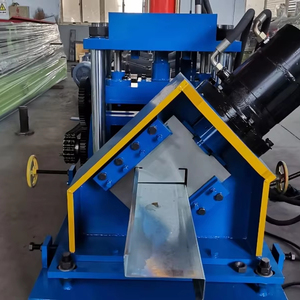

Custom C Purlin Roll Forming Machine Price

Top sponsor listing

Top sponsor listing

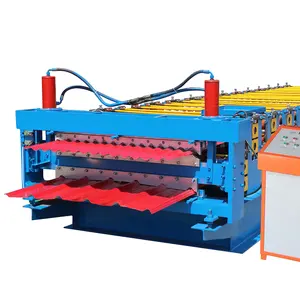

1/13

1/13

1/13

1/13

CN

CN

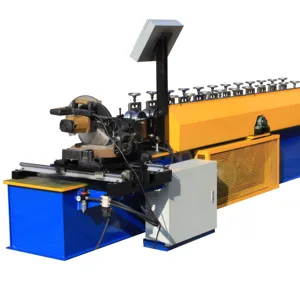

1/17

1/17

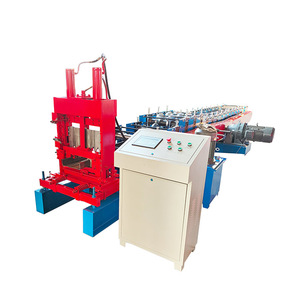

1/19

1/19

CN

CN

1/19

1/19

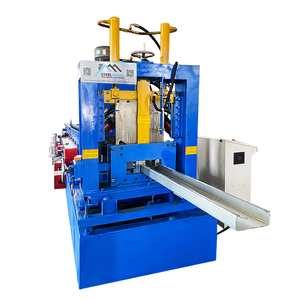

1/22

1/22

1/22

1/22

CN

CN

1/18

1/18

1/27

1/27

1/11

1/11

1/14

1/14

1/19

1/19

About custom c purlin roll forming machine price

Where to Find Custom C Purlin Roll Forming Machine Suppliers?

China remains the dominant hub for manufacturing custom C purlin roll forming machines, with key production clusters concentrated in Hebei, Tianjin, and Henan provinces. These regions host vertically integrated industrial ecosystems that combine precision metalworking, automation engineering, and supply chain logistics. Hebei and Tianjin are particularly notable for their specialization in light steel framing systems, where suppliers benefit from proximity to major steel mills and ports, reducing raw material costs and transit times by up to 25% compared to non-specialized regions.

The concentration of component manufacturers—such as decoiler, roller die, and hydraulic system producers—within a 50-kilometer radius enables rapid prototyping and assembly. This localized supply network supports efficient customization cycles and shortens lead times to 30–45 days for standard configurations. Buyers gain access to scalable production lines capable of processing galvanized, pre-painted, and aluminum coils with thicknesses ranging from 0.3mm to 4.0mm, accommodating diverse structural requirements across residential, commercial, and industrial construction sectors.

How to Choose Custom C Purlin Roll Forming Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation based on technical capability, quality assurance, and transaction reliability:

Technical & Production Capabilities

Prioritize suppliers with demonstrated expertise in cold roll forming technology and structural steel profile design. Verify the presence of in-house R&D teams responsible for roller configuration design, tooling calibration, and PLC control integration. Key indicators include:

- Minimum factory area exceeding 3,000m² to support dedicated production lines

- In-house CNC machining and welding capabilities for roller dies and frame assembly

- Customization scope covering coil width (120–600mm), thickness (0.3–4.0mm), hole patterns, color coding, and packaging labeling

- Support for third-party inspection and video call audits during commissioning

Cross-reference supplier claims with verified performance metrics such as on-time delivery rates (target ≥98%) and response times (ideally ≤2 hours).

Quality Management Systems

While ISO 9001 certification is not universally listed, consistent on-time delivery (100% across multiple suppliers) and high reorder rates suggest robust internal quality controls. For international compliance, confirm CE marking or equivalent safety standards if exporting to EU or North American markets. Request documentation for material traceability, hydraulic system testing, and electrical panel certifications (e.g., IP54 rating).

Transaction Security & After-Sales Support

Utilize secure payment mechanisms such as escrow services to mitigate risk. Evaluate suppliers based on reorder rates—an indicator of customer satisfaction—with top performers exceeding 60%. Confirm availability of remote technical support via video call and provision of operational manuals, spare parts lists, and training protocols. Sample testing is recommended: request machine operation videos or physical samples of formed C purlins to verify dimensional accuracy and surface finish consistency.

What Are the Best Custom C Purlin Roll Forming Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Services |

|---|---|---|---|---|---|---|---|---|

| Hebei Feixiang Roll Forming Machinery Co., Ltd. | Hebei, CN | Steel Frame & Purlin Machines, Tile Making Machinery | US $90,000+ | 100% | ≤4h | 100% | $103,000–107,000 | Yes |

| Hangzhou Zhongyuan Machinery Factory | Zhejiang, CN | Steel Frame & Purlin Machines, Pipe Making Machinery | Not disclosed | 100% | ≤2h | - | $41,000–107,000 | Yes |

| Cangzhou Zhongheng Machine Manufacture Co., Ltd. | Hebei, CN | Steel Frame & Purlin Machines, Window & Door Machinery | US $410,000+ | 100% | ≤4h | 100% | $11,000–35,000 | Yes |

| Zhengzhou Hokang Machinery Co., Ltd. | Henan, CN | Custom C/Z/U Purlin Machines | US $290,000+ | 100% | ≤1h | 28% | $6,500–12,000 | Yes |

| Tianjin Haixing Imp & Exp Co., Ltd. | Tianjin, CN | C-Purlin Machines, Light Steel Keel Equipment | US $1,100,000+ | 100% | ≤1h | 60% | $9,000–29,000 | Yes |

Performance Analysis

Suppliers vary significantly in pricing and scale, reflecting differences in automation level and target market. High-end manufacturers like Hebei Feixiang offer full-automatic systems priced above $100,000, suitable for large-scale industrial operations requiring minimal manual intervention. In contrast, Zhengzhou Hokang and Tianjin Haixing provide cost-effective semi-automatic models under $30,000, ideal for SMEs and emerging markets. Notably, Cangzhou Zhongheng and Hebei Feixiang achieve perfect reorder rates (100%), indicating strong customer retention through consistent quality and post-sale service. Tianjin-based suppliers demonstrate superior responsiveness, with average reply times under one hour, enhancing communication efficiency during technical negotiations. All listed suppliers support customization of roller configuration, material thickness, and output speed, but only verified manufacturers offer comprehensive design validation and third-party inspection coordination.

FAQs

How to verify custom C purlin roll forming machine supplier reliability?

Validate supplier credentials through documented proof of production facilities, client references, and quality control procedures. Conduct virtual audits via video calls to inspect machinery assembly lines and testing processes. Analyze transaction history focusing on on-time delivery performance, reorder rates, and responsiveness. For critical procurement, engage third-party inspection agencies to assess machine build quality prior to shipment.

What is the typical lead time for custom orders?

Standard lead times range from 30 to 45 days after order confirmation, depending on complexity and automation level. Fully customized configurations involving unique roller dies or PLC programming may extend timelines to 60 days. Expedited production can be negotiated with suppliers maintaining modular component inventories.

What customization options are available?

Suppliers commonly offer adjustments to coil width (up to 600mm), material thickness (0.3–4.0mm), punch hole patterns, color coding, and logo imprinting. Advanced options include variable-speed drives, quick-size change mechanisms, and integration with cutting and stacking units. Technical drawings and CAD files are typically required to finalize specifications.

Do suppliers provide installation and training support?

Most suppliers offer remote guidance via video tutorials and live calls. On-site installation and operator training can be arranged at additional cost, typically billed at $150–$200 per technician day, excluding travel expenses. Ensure service terms are defined in the contract before shipment.

What are common payment and shipping terms?

Standard payment terms include 30% advance T/T with balance paid before shipment. Trade Assurance or letter of credit options enhance transaction security. Shipping is typically FOB from major Chinese ports (Tianjin, Qingdao, Ningbo), with sea freight recommended for single-machine shipments due to size and weight considerations.