Custom Circuit Board Assembly

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

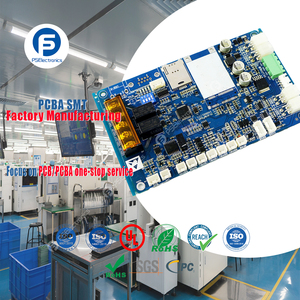

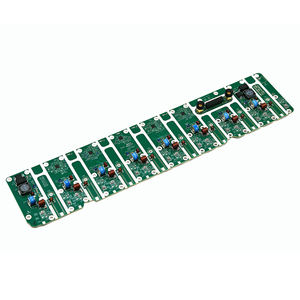

About custom circuit board assembly

Where to Source Custom Circuit Board Assembly Suppliers?

China remains the central hub for custom circuit board assembly (PCBA) manufacturing, with concentrated supplier clusters in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated facilities that combine PCB fabrication, surface mount technology (SMT), automated optical inspection (AOI), and final box-build assembly under one roof. Proximity to component distribution hubs like Shenzhen’s Huaqiangbei enables rapid sourcing of active and passive components, reducing material lead times by 10–15 days compared to offshore alternatives.

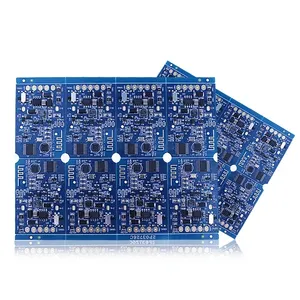

The ecosystem supports both low-volume prototyping and high-volume production, with many suppliers offering one-stop services from Gerber file review to full turnkey assembly. This integration reduces coordination overhead and accelerates time-to-market. Buyers benefit from scalable production lines capable of handling single-layer, multilayer, rigid-flex, and high-frequency PCBs using FR-4, Rogers, and polyimide substrates. Average cost savings range from 25% to 40% versus domestic Western manufacturers, particularly for orders exceeding 500 units.

How to Evaluate Custom Circuit Board Assembly Suppliers?

Selecting a reliable partner requires systematic assessment across technical, operational, and transactional dimensions:

Technical & Process Capabilities

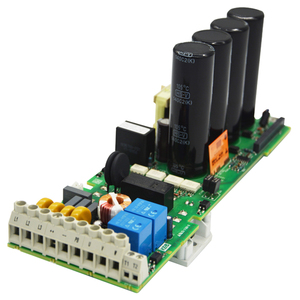

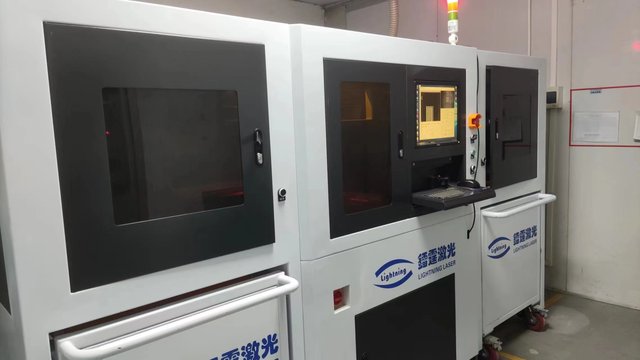

Confirm support for key processes including SMT, through-hole assembly, BGA reflow, IC programming, and conformal coating. Advanced suppliers offer reverse engineering, PCB cloning, and design-for-manufacturability (DFM) analysis. Look for capabilities in fine-pitch components (<0.4mm pitch), micro BGAs, and high-amperage power circuits. Automated optical inspection (AOI) and X-ray inspection for hidden solder joints are indicators of robust quality control.

Quality Management Systems

Prioritize suppliers with ISO 9001 certification and adherence to IPC-A-610 Class 2 or Class 3 standards. RoHS and REACH compliance is essential for shipments to Europe and North America. Verify implementation of solder paste inspection (SPI), in-circuit testing (ICT), and functional testing protocols. Some providers offer full traceability via barcode tracking per batch or serial number.

Production Flexibility and Scalability

Assess minimum order quantity (MOQ) policies—some suppliers accept MOQs as low as 1 piece for prototypes, while others require 10–100 pieces for cost efficiency. Monthly production capacity should align with demand forecasts; leading facilities report output exceeding 500,000 assembled boards. Evaluate responsiveness metrics: sub-2-hour response times correlate with higher service engagement, especially during design iterations.

What Are the Top Custom Circuit Board Assembly Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response Time | Online Revenue | Customization Scope | Key Services | Verified Status |

|---|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | Multilayer PCB, PCBA, High-Frequency Boards | 100% | 66% | ≤1h | US $1,000+ | Full turnkey, wearable electronics, high-frequency designs | OEM/ODM, SMT, BOM sourcing, box build, cloning | Multispecialty Supplier |

| Tecoo Electronics Co., Ltd. | Rigid-Flex, Precision PCBA, Smart Electronics | 98% | 32% | ≤3h | US $460,000+ | High-precision assembly, IC programming, global component sourcing | Automated inspection, DFM, reverse engineering, packaging | - |

| Pinsheng Electronics Co., Ltd. | One-Stop PCBA, SMT, Prototype Assembly | 100% | <15% | ≤2h | US $1,000+ | Gerber/BOM-based builds, small-batch customization | Solder paste inspection, sample boards, logo printing | Multispecialty Supplier |

| Dongguan Xinrongxing Technology Co., Ltd. | Single-Sided PCB, OSP Finish, Fan Control Boards | 100% | 25% | ≤3h | US $10,000+ | Copper thickness variation, color mask options, edge finishing | OEM assembly, tin spray, white/blue silkscreen | Multispecialty Supplier |

Performance Analysis

Toptek Pcb Co., Limited stands out with a 100% on-time delivery rate and a 66% reorder rate, indicating strong customer retention and operational reliability. Its ability to handle high-frequency and wearable electronics makes it suitable for advanced applications. Tecoo Electronics demonstrates extensive engineering depth, supporting complex workflows such as IC programming, automated inspection, and reverse engineering—critical for product development cycles. Pinsheng Electronics offers exceptional flexibility with MOQs starting at one piece and rapid turnaround, ideal for startups and R&D teams. Dongguan Xinrongxing specializes in cost-effective single-sided PCBs with customizable surface finishes, catering to consumer electronics and appliance sectors.

FAQs

How to verify a PCBA supplier's technical reliability?

Request evidence of ISO 9001 certification and sample test reports, including AOI logs, ICT results, and functional test procedures. Conduct virtual audits via video tours to assess factory layout, SMT line configuration, and inventory management systems. Confirm experience with your specific PCB type (e.g., multilayer, rigid-flex).

What is the typical lead time for custom PCBA?

Prototype assemblies typically take 7–10 days, including component procurement. Full production runs (1,000+ units) require 15–25 days depending on complexity and supply chain availability. Expedited services may reduce timelines by 3–5 days at additional cost.

Do suppliers support component sourcing and BOM optimization?

Yes, most one-stop providers offer BOM analysis, alternative part substitution, and lifecycle verification. Leading suppliers maintain relationships with authorized distributors and can source long-lead or obsolete components, reducing project delays.

Are there minimum order requirements?

MOQ varies by supplier and complexity. Some accept 1-piece orders for prototypes, while production batches typically start at 10–100 units. Pricing scales favorably beyond 500 units due to fixed setup cost amortization.

Can suppliers handle end-to-end product realization?

Top-tier providers offer full product realization—from schematic design and PCB layout to assembly, programming, enclosure integration, and packaging. Confirm scope early, as not all suppliers provide design services or box-build assembly.