Custom Circuit Board Maker

CN

CN

CN

CN

CN

CN

About custom circuit board maker

Where to Find Custom Circuit Board Makers?

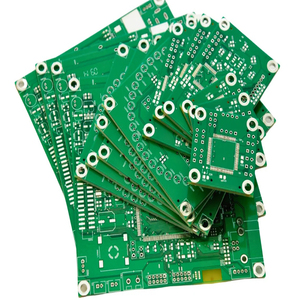

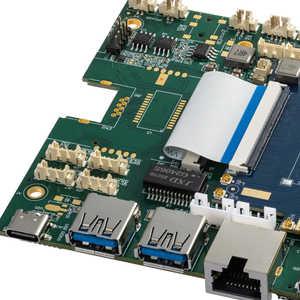

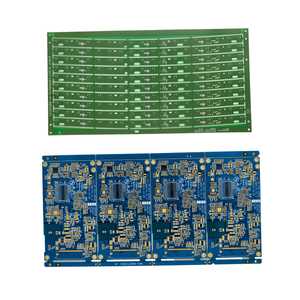

China remains the global hub for custom printed circuit board (PCB) manufacturing, with concentrated supplier clusters in Guangdong Province—particularly Shenzhen and Dongguan—driving innovation and cost efficiency. These regions host vertically integrated facilities equipped with full-cycle production lines covering PCB fabrication, surface mount technology (SMT), through-hole assembly, and final testing. Suppliers leverage localized access to raw materials such as FR-4, aluminum substrates, and high-frequency laminates, reducing material procurement lead times by 20–30% compared to offshore alternatives.

The ecosystem supports rapid prototyping and scalable volume production, enabling turnaround times as fast as 24 hours for simple 2-layer boards and 5–7 days for complex multilayer assemblies. With average factory areas exceeding 3,000m² and monthly output capacity reaching tens of thousands of units, these manufacturers serve industries ranging from consumer electronics and IoT to industrial automation and renewable energy systems. Buyers benefit from flexible minimum order quantities (MOQs), often starting at 1 piece for prototypes, and competitive pricing structures that scale significantly at volumes above 200 units.

How to Choose a Custom Circuit Board Maker?

Selecting a reliable PCB manufacturer requires rigorous evaluation across technical, operational, and transactional dimensions:

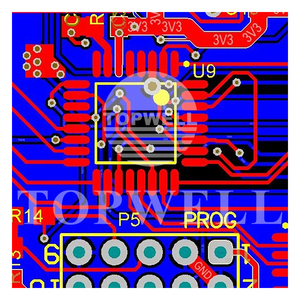

Production and Technical Capabilities

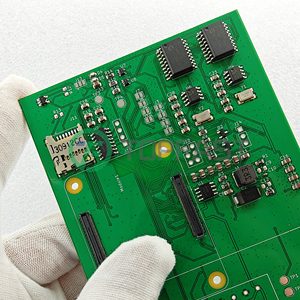

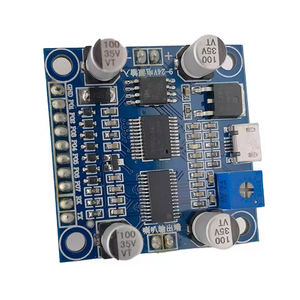

Verify that suppliers operate their own SMT lines, automated optical inspection (AOI), and functional testing equipment. Prioritize partners offering one-stop services including schematic design, Gerber file validation, component sourcing, and enclosure integration. Key benchmarks include support for up to 16-layer boards, impedance control, blind/buried vias, and RF or power module integration. For advanced applications, confirm experience with HDI, rigid-flex, or metal-core PCBs.

Quality Assurance and Compliance

Ensure adherence to IPC-A-610 Class 2 standards as a baseline. While not all suppliers list ISO 9001 certification explicitly, consistent on-time delivery rates above 97% and documented quality control processes indicate robust internal systems. For export-bound electronics, compliance with RoHS and REACH directives is essential. Request evidence of solder joint reliability testing, thermal cycling reports, and first-article inspections for critical designs.

Customization and IP Protection

Assess the breadth of customization options: board material, thickness, copper weight, finish (HASL, ENIG, OSP), silkscreen, impedance matching, and firmware programming. Reputable suppliers offer confidentiality agreements (NDAs) to protect intellectual property during development. Confirm secure handling of design files, especially Gerber, BOM, and pick-and-place data.

Transaction Reliability Metrics

Use verified performance indicators to assess reliability:

- On-time delivery rate ≥97%

- Average response time ≤4 hours

- Reorder rate >30% indicating customer retention

- Escrow-backed transactions or trade assurance programs

Cross-reference online revenue estimates and order history where available to gauge business scale and market trust. Conduct video audits of production floors before placing large orders.

What Are the Leading Custom Circuit Board Makers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Key Customization Features |

|---|---|---|---|---|---|---|---|

| DONGGUAN TOPWELL TECHNOLOGY CO.,LTD | Dongguan, CN | Custom Manufacturer | US $680,000+ | 100% | ≤3h | 18% | PCB design, material selection, assembly, enclosure, firmware, RF modules, structural design |

| Dongguan Xinhao Technology Co., Ltd. | Dongguan, CN | Custom Manufacturer | US $1,000+ | 100% | ≤4h | 50% | Material, color, size, logo, packaging, label, graphic design |

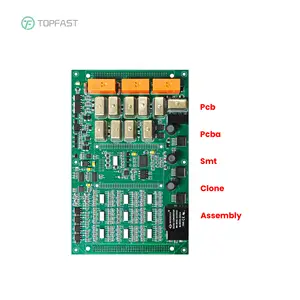

| Topfast Technology Co.,Ltd. | Shenzhen, CN | Custom Manufacturer | US $610,000+ | 97% | ≤4h | 45% | Prototyping, PCBA, wave soldering, microcontroller integration, Gerber proofing |

| Shenzhen Kingfung Technology Co., Ltd. | Shenzhen, CN | — | US $10,000+ | 100% | ≤4h | 28% | Solar inverters, energy storage, lithium-ion battery packs, home appliance PCBs |

| Shenzhen Yidasheng Electronics Co., Ltd. | Shenzhen, CN | Multispecialty Supplier | US $500+ | 100% | ≤2h | 33% | Material, color, size, logo, packaging, label, graphic customization |

Performance Analysis

DONGGUAN TOPWELL and Topfast Technology demonstrate strong technical depth with comprehensive design-to-assembly capabilities and high annual revenues, making them suitable for mid-to-high volume clients requiring full-stack engineering support. Dongguan Xinhao stands out with a 50% reorder rate—the highest in the dataset—indicating strong client satisfaction despite lower reported revenue, suggesting niche specialization or lean operations. Shenzhen Yidasheng excels in responsiveness (≤2h average reply time) and offers ultra-low MOQs starting at $0.10 per unit, ideal for startups and R&D teams needing rapid iteration. All top-tier suppliers maintain 100% on-time delivery records, a critical factor for just-in-time production planning. For specialized applications like power electronics or solar energy systems, Shenzhen Kingfung provides domain-specific expertise validated through product focus.

FAQs

What is the typical lead time for custom PCBs?

Prototype batches (1–10 pcs) typically ship within 3–5 working days. Volume orders (100+ units) take 7–12 days depending on complexity. Rush services are available for expedited 24–48 hour turnaround on select 1–2 layer boards.

Do custom circuit board makers accept small MOQs?

Yes, most suppliers accommodate MOQs as low as 1 piece for prototyping. Unit costs decrease significantly at 200+ units due to economies of scale in stencil and setup charges.

Can I request a confidentiality agreement (NDA)?

Reputable manufacturers allow NDA signing to protect sensitive designs and intellectual property. This is standard practice for commercial and industrial clients.

What file formats are required for PCB production?

Standard deliverables include Gerber files (RS-274X), drill files, centroid data, BOM, and pick-and-place files. Some suppliers also accept EAGLE (.brd), Altium, KiCad, or PDF schematics for conversion.

How are quality issues resolved post-shipment?

Suppliers typically offer rework or replacement for defects attributed to manufacturing errors, provided failure analysis confirms non-user origin. Pre-shipment inspection reports and AOI logs should be requested to establish baseline quality.