Circuit Board Maker

Top sponsor listing

Top sponsor listing

CN

CN

About circuit board maker

Where to Find Circuit Board Maker Suppliers?

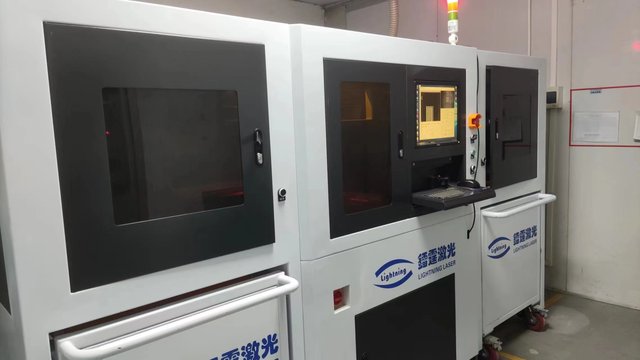

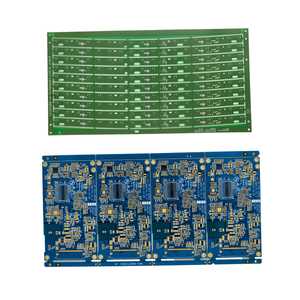

China remains the global epicenter for printed circuit board (PCB) manufacturing, with Shenzhen and Suzhou emerging as key industrial hubs due to concentrated supply chains, skilled labor pools, and advanced production infrastructure. Shenzhen dominates high-mix, low-to-medium volume electronics fabrication, particularly for consumer devices, IoT, and telecommunications equipment. Its ecosystem supports rapid prototyping and agile manufacturing, with many suppliers offering turnkey PCBA services from design to final assembly.

Suzhou complements this with a focus on precision engineering and industrial-grade PCBs used in automation, medical devices, and automotive systems. The region benefits from proximity to semiconductor research centers and logistics gateways like Shanghai Port, enabling efficient export operations. These clusters provide buyers access to vertically integrated facilities capable of handling single-layer to multilayer rigid, flexible (FPC), and rigid-flex boards. Typical advantages include scalable production capacity, 20–35% cost efficiency over Western manufacturers, and lead times averaging 7–15 days for prototypes and 15–25 days for mass production.

How to Choose Circuit Board Maker Suppliers?

Selecting a reliable circuit board maker requires systematic evaluation across technical, operational, and transactional dimensions:

Production Capabilities Verification

Confirm ownership of in-house production lines to ensure control over quality and scheduling. Prioritize suppliers equipped for core processes including photolithography, etching, drilling, plating, and SMT assembly. Key benchmarks include:

- Facility size supporting monthly output of ≥10,000 units

- Certified cleanrooms and automated optical inspection (AOI) systems

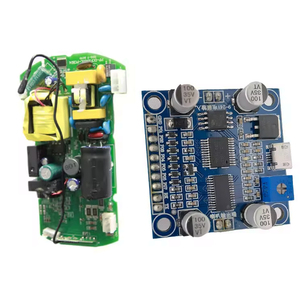

- Support for FR-4, aluminum substrates, polyimide (for FPC), and HDI technologies

- Minimum trace width/spacing capability ≤4 mil and via diameters ≤0.3mm

Cross-reference claims with verifiable metrics such as on-time delivery rates (target ≥95%) and response times (ideally ≤3 hours).

Quality & Compliance Standards

Demand adherence to IPC-A-600H (acceptability of printed boards) and IPC-A-610 (electronics assembly acceptance). ISO 9001 certification is essential for process consistency; for export markets, validate compliance with RoHS, REACH, and UL standards where applicable. Review test reports including flying probe testing, X-ray inspection for BGA joints, and thermal cycling results for reliability-critical applications.

Customization & Scalability Assessment

Evaluate flexibility in accommodating custom specifications:

- Layer count: 1–16+ layers supported

- Board thickness range: 0.2–3.2mm standard

- Surface finishes: HASL, ENIG, Immersion Silver/Tin, OSP

- Logo, silkscreen color, and packaging personalization options

Transaction Security Measures

Utilize secure payment mechanisms such as escrow or milestone-based releases tied to production milestones. Verify supplier transaction history through documented revenue ranges and repeat order patterns. Prototype validation is critical—request functional testing reports and physical samples before scaling to full production runs.

What Are the Best Circuit Board Maker Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Verification Status |

|---|---|---|---|---|---|---|---|---|

| Suzhou Engine Electronic Technology Co., Ltd. | Suzhou, CN | PCBA, Multilayer PCB, Other PCB & PCBA | 91% | ≤3h | 15% | US $50,000+ | Color, size, logo, packaging, label, engineering | Multispecialty Supplier |

| Shenzhen Yongkefeng Technology Co., Ltd. | Shenzhen, CN | PCBA, Multilayer PCB, FPC, Double-sided PCB | 100% | ≤1h | 25% | US $70,000+ | Limited customization noted | - |

| Shenzhen Tobaina Technology Co., Ltd. | Shenzhen, CN | PCBA, Rigid-Flex PCB, Communication Antennas | 100% | ≤1h | <15% | US $50,000+ | Design, material, size, OEM branding | - |

| Dalian Jy Electronics & Technology Co., Ltd. | Dalian, CN | PCBA, Prototype Services, Turnkey Assembly | 100% | ≤1h | 44% | US $300,000+ | Color, material, size, logo, packaging, graphic | Custom Manufacturer |

| Wuxi Lilai Technology Co., Ltd. | Wuxi, CN | PCBA, Consumer Electronics, Battery Modules | 100% | ≤14h | 100% | US $300+ | OEM processing, hardware/software integration | - |

Performance Analysis

Dalian Jy Electronics stands out with the highest reorder rate (44%) and robust customization capabilities, indicating strong client retention and service adaptability. Shenzhen-based suppliers—Yongkefeng and Tobaina—achieve perfect on-time delivery records and sub-1-hour response times, reflecting operational efficiency typical of southern China’s fast-paced electronics sector. Wuxi Lilai, despite lower reported online revenue, demonstrates exceptional loyalty with a 100% reorder rate, suggesting niche specialization in battery-integrated PCBA solutions. Suzhou Engine Electronic, while slightly below benchmark in delivery performance (91%), offers broad customization scope suitable for complex industrial designs.

FAQs

How to verify circuit board maker reliability?

Validate certifications (ISO 9001, IPC membership), request factory audit reports or video tours, and review third-party inspection documentation. Analyze historical transaction data including on-time delivery rate, response speed, and reorder frequency as behavioral indicators of dependability.

What is the typical MOQ and pricing structure?

Most suppliers support MOQs as low as 1 piece for prototypes, with unit costs ranging from $0.10–$10 depending on complexity. High-volume orders (≥1,000 pcs) achieve economies of scale, reducing per-unit costs by up to 60%. Multilayer and rigid-flex boards command premium pricing due to added processing steps.

Do suppliers offer design and engineering support?

Yes, many provide free Gerber file review, DFM analysis, and component sourcing assistance. Some offer full turnkey development including firmware integration and enclosure design coordination, especially those labeled as "Custom Manufacturers."

Can PCB suppliers handle global shipping?

All listed suppliers have export experience, primarily shipping via air freight for samples and sea containers for bulk orders. Confirm Incoterms (e.g., FOB Shenzhen, CIF Rotterdam) and ensure packaging meets ESD protection standards for sensitive electronic assemblies.

What are common lead times for PCB production?

Standard prototypes: 5–7 days. Multilayer or impedance-controlled boards: 10–15 days. Mass production (1,000+ units): 15–25 days including component procurement and functional testing. Expedited services may reduce timelines by 30–50% at additional cost.