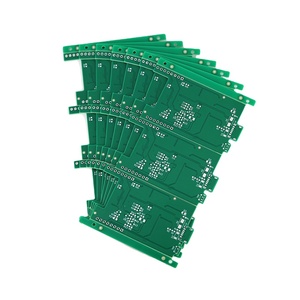

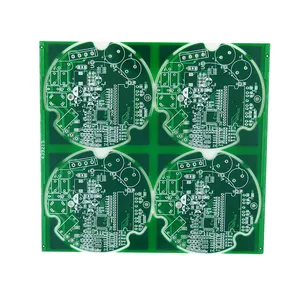

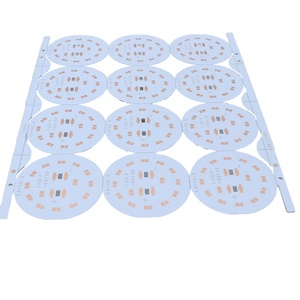

Circuit Board Maker Machine

About circuit board maker machine

Where to Find Circuit Board Maker Machine Suppliers?

China remains the global epicenter for printed circuit board (PCB) manufacturing equipment, with key industrial clusters concentrated in Guangdong, Jiangsu, and Hunan provinces. These regions host vertically integrated ecosystems that combine precision engineering, electronics production expertise, and robust supply chains for raw materials such as copper-clad laminates and insulating resins. Shenzhen and Dongguan in Guangdong Province specialize in high-precision automation systems, including silk-screen printers, pick-and-place machines, and CCD alignment units, supporting rapid prototyping and mass production of multilayer PCBs.

Jiangsu and Hunan have emerged as hubs for lamination and pressing machinery, critical in bonding multi-layer boards under controlled heat and pressure. The proximity of component suppliers, CNC machining workshops, and testing facilities within 50km radii enables streamlined assembly of complete production lines. Buyers benefit from reduced lead times—typically 30–45 days for standard configurations—and cost advantages, with Chinese suppliers offering 20–35% lower pricing compared to European or North American manufacturers due to localized sourcing and operational scale.

How to Choose Circuit Board Maker Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Process Capability

Verify adherence to international quality standards such as ISO 9001 and CE marking, particularly for electrical safety and electromagnetic compatibility. For buyers targeting EU markets, RoHS compliance is essential to ensure restricted substance control in production environments. Request documentation on machine tolerances, thermal stability (±2°C for lamination presses), and positioning accuracy (e.g., ±0.01mm for automated silk-screen systems).

Production Infrastructure Assessment

Evaluate core manufacturing capabilities through objective benchmarks:

- Facility size exceeding 3,000m² indicating capacity for full-line assembly

- In-house R&D teams focused on automation integration and process optimization

- Vertical integration covering CNC machining, hydraulic system calibration, and control software development

Cross-reference claimed capabilities with on-time delivery performance (target ≥97%) and response time metrics (ideally ≤2 hours) to assess operational responsiveness.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align financial release with equipment verification at destination. Prioritize suppliers with transparent transaction histories, verified reorder rates, and participation in third-party assurance programs. Pre-shipment inspection and functional testing are critical—request live demonstrations or video audits of machine operation before finalizing orders.

What Are the Best Circuit Board Maker Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Dipu Industrial Limited By Share Ltd | Jiangsu, CN | Electronics Production Machinery (519) | 100.0% | ≤2h | - | - | $8,000–220,000 | 1 set |

| Shenzhen Chikin Automation Equipment Co., Ltd. | Guangdong, CN | Electronics Production Machinery (252) | 100.0% | ≤3h | 25% | US $350,000+ | $8,000–75,000 | 1 set |

| Changsha Suny Electronic Technology Limited | Hunan, CN | Testing Equipment (126), Electronics Production Machinery (97) | 100.0% | ≤12h | <15% | - | $100–60,000 | 1 piece/set |

| Chengshengjie Technology (Huizhou) Co., Ltd. | Guangdong, CN | Electronics Production Machinery (75) | 100.0% | ≤1h | - | - | $5,000–60,000 | 1 piece |

| Jiaxing Bovi Electronic Technology Co., Ltd. | Zhejiang, CN | Electronics Production Machinery (170) | - | ≤3h | - | US $20,000+ | $8,900–14,700 | 1 set |

Performance Analysis

Jiangsu Dipu stands out for its focus on high-capacity lamination and insulation pressing systems, offering machines priced up to $220,000, suitable for industrial-scale multilayer PCB fabrication. Shenzhen Chikin provides diversified solutions, including automatic MCPCB and silk-screen printing machines, backed by strong online revenue and a 25% reorder rate, indicating customer retention. Chengshengjie Technology demonstrates fast responsiveness (≤1h), a key advantage for urgent procurement cycles, though its product listings suggest a mix of core machinery and peripheral components.

Changsha Suny offers entry-level etching and prototype equipment starting at $100, catering to R&D labs and small-batch producers, but slower response times may impact project timelines. Jiaxing Bovi focuses on mid-range SMT assembly systems with competitive pricing, though absence of on-time delivery data warrants further due diligence. Buyers seeking turnkey production lines should prioritize suppliers with comprehensive electronics machinery portfolios and proven export experience.

FAQs

How to verify circuit board maker machine supplier reliability?

Validate certifications (ISO, CE) through official registries and request factory audit reports. Analyze customer feedback focusing on after-sales service, software support, and mechanical uptime. Conduct video inspections of production floors and test runs to confirm technical claims.

What is the typical lead time for PCB machinery?

Standard machines ship within 30–45 days after order confirmation. Customized systems involving multi-axis alignment or integrated vision inspection may require 60–75 days. Air freight reduces transit time to 5–7 days; sea freight averages 25–35 days depending on destination port.

Do suppliers offer customization for PCB production lines?

Yes, most established suppliers provide OEM/ODM services. Customization includes conveyor width adjustments, PLC interface integration, temperature control ranges (120–180°C), and compatibility with FR-4, aluminum, or polyimide substrates. Technical specifications must be submitted in CAD or STEP format for engineering review.

What are common MOQ and pricing structures?

Minimum order quantities typically start at 1 set for complete machines. Entry-level units begin around $5,000, while fully automated lines exceed $200,000. Some suppliers offer modular pricing for incremental line expansion. Bulk orders may qualify for container-load discounts and reduced per-unit shipping costs.

Can suppliers assist with installation and training?

Reputable manufacturers provide remote commissioning support via video guidance. On-site installation and operator training are often available at additional cost, typically $150–200/hour plus travel expenses. Post-warranty service contracts are negotiable and recommended for continuous operation.