Printed Circuit Board Maker

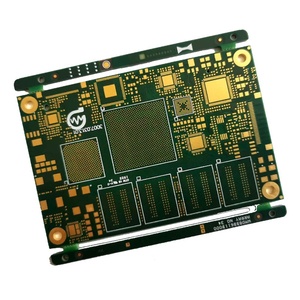

About printed circuit board maker

Where to Find Printed Circuit Board Maker Suppliers?

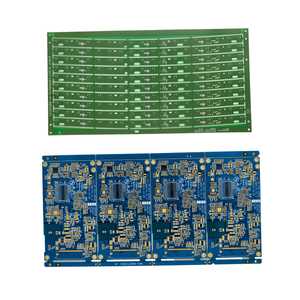

China remains the global hub for printed circuit board (PCB) manufacturing, with Shenzhen and Dongguan serving as core production centers due to their dense electronics ecosystems. These regions host vertically integrated facilities capable of handling prototyping, small-batch production, and high-volume turnkey assembly. Suppliers in this cluster benefit from proximity to component distributors, specialized material suppliers, and logistics networks, enabling rapid turnaround and cost efficiency.

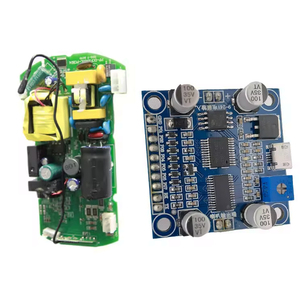

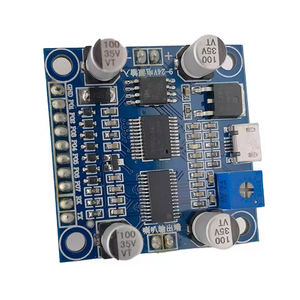

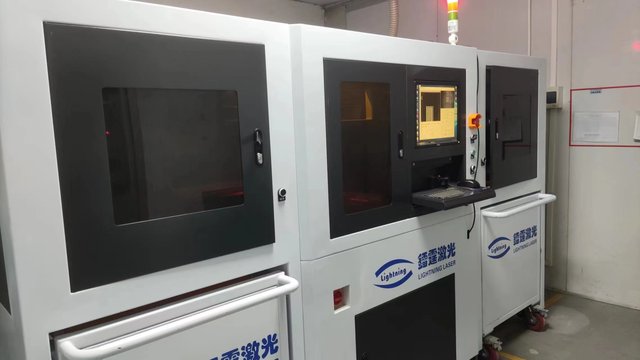

The industrial advantage lies in scalable production infrastructure—many PCB makers operate automated SMT lines, AOI inspection systems, and in-house design teams, supporting full-cycle services from bare board fabrication to final PCBA testing. Buyers gain access to flexible MOQs (as low as 1 piece), fast lead times (5–15 days for prototypes), and advanced capabilities including multilayer, rigid-flex, and HDI boards. Cost savings range from 20–40% compared to Western or Southeast Asian manufacturers, driven by localized supply chains and automation.

How to Choose Printed Circuit Board Maker Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional criteria:

Technical & Production Capabilities

Verify that suppliers support required specifications:

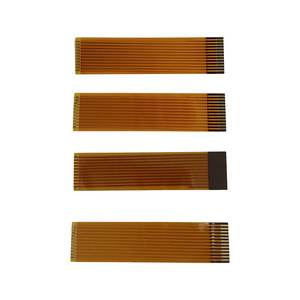

- Layer count: Single-sided, double-sided, multilayer (up to 20+ layers)

- Materials: FR-4, aluminum substrate, Rogers, polyimide (for flex/rigid-flex)

- Copper thickness: Standard (1oz) to heavy copper (3–6oz) options

- Surface finishes: HASL, ENIG, immersion silver/tin, OSP

- Minimum trace/spacing: Down to 3–4 mil for high-density designs

- In-house processes: SMT, THT, reflow, wave soldering, AOI, X-ray inspection, ICT, functional testing

Prioritize suppliers with documented engineering support, including DFM analysis, BOM optimization, and reverse engineering capabilities.

Quality Assurance & Compliance

Confirm adherence to international standards:

- ISO 9001-certified quality management systems

- IPC-A-610 Class 2 or Class 3 compliance for assembly

- RoHS, REACH, and UL material declarations

- Automated optical inspection (AOI) and first-article inspection protocols

Request sample reports such as solder paste inspection (SPI) data, test logs, and packaging standards to assess consistency.

Transaction Reliability & Service Metrics

Evaluate performance indicators available through verified trading histories:

- On-time delivery rate ≥98%

- Average response time ≤2 hours

- Reorder rate above 25% indicates customer retention

- Transparent pricing structures with clear MOQ-based tiers

Use incremental ordering strategies—start with prototype batches—to validate quality before scaling.

What Are the Best Printed Circuit Board Maker Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Response Time | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Tecoo Electronics Co., Ltd. | Shenzhen, CN | High-precision medical PCBA, rigid-flex, reverse engineering | Full turnkey, BOM sourcing, IC programming, cloning | 98% | ≤2h | 35% | 10 pcs | $0.50–$15.23 |

| Dongguan Xinrongxing Technology Co., Ltd. | Dongguan, CN | Single/double-sided, FR-4 multilayer, medical PCB | White/blue solder mask, edge plating, custom finish | 100% | ≤2h | 25% | 1 pc | $0.25–$1.10 |

| Shenzhen Yongkefeng Technology Co., Ltd. | Shenzhen, CN | PCBA, multilayer PCB, OEM/ODM cloning | Prototype to mass production, 18+ years experience | 100% | ≤1h | 25% | 1 pc | $122–$288 |

| Shenzhen Tobaina Technology Co., Ltd. | Shenzhen, CN | Multilayer PCB, AI recorder, GNSS modules | Rigid-flex, automated assembly, AI integration | 100% | ≤1h | <15% | 1 pc | $0.30–$15.00 |

| Shenzhen Shangfeng Electronics Co., Ltd. | Shenzhen, CN | Multilayer PCB, education/maker boards, imaging sensors | OEM/ODM, 3D printing integration, rapid prototyping | 100% | ≤2h | 66% | 5 pcs | $0.90–$10.00 |

Performance Analysis

Tecoo Electronics stands out for high-precision applications, particularly in medical and aerospace sectors, offering comprehensive turnkey solutions and a strong reorder rate of 35%. Dongguan Xinrongxing excels in low-MOQ flexibility with prices starting at $0.25 and 1-piece minimums, ideal for startups and R&D teams. Shenzhen Yongkefeng and Tobaina both offer 100% on-time delivery and sub-2-hour response times, with Yongkefeng emphasizing long-term expertise (18+ years) and Tobaina integrating communication modules into PCBAs. Shenzhen Shangfeng leads in customer retention (66% reorder rate), indicating high satisfaction in prototyping and maker-focused segments. All five suppliers support customization, but depth varies—prioritize those with in-house engineering workshops and component sourcing capabilities for complex builds.

FAQs

How to verify a printed circuit board maker’s reliability?

Cross-check ISO and IPC compliance claims with documentation. Request facility videos showing SMT lines, inspection stations, and warehouse operations. Analyze transaction metrics such as on-time delivery, response speed, and reorder rates. Conduct third-party inspections for initial batch validation.

What is the typical lead time for PCB prototypes?

Standard single/double-sided boards take 5–7 days. Multilayer (6–12 layers) require 8–12 days. High-complexity or rigid-flex boards may extend to 15 days. Rush services are often available for an additional fee.

Do PCB suppliers offer free samples?

Most charge for initial prototypes, especially for turnkey assemblies involving components. Some waive fees if followed by volume orders (e.g., 100+ units). Bare board samples may be offered at reduced cost for qualified buyers.

Can suppliers handle component sourcing and BOM management?

Yes, many provide full BOM analysis, alternative part substitution, and global component procurement. Top-tier suppliers maintain partnerships with authorized distributors to ensure authenticity and mitigate obsolescence risks.

What are common MOQs and pricing models?

MOQs range from 1 to 100 pieces depending on complexity. Pricing is tiered: lower per-unit costs at higher volumes. Simple single-layer boards start under $0.50/unit at 100 pcs; multilayer or mixed-technology assemblies exceed $5–$20/unit. Transparent quotes include fabrication, assembly, stencil, and testing fees.