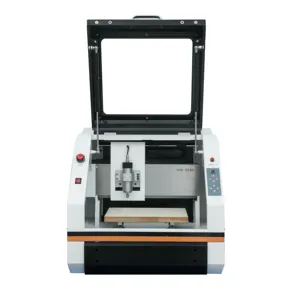

Pcb Maker Machine

Top sponsor listing

Top sponsor listing

About pcb maker machine

Where to Find PCB Maker Machine Suppliers?

China remains the global epicenter for PCB maker machine manufacturing, with key industrial clusters in Guangdong and Zhejiang provinces driving innovation and scale. Dongguan and Shenzhen in Guangdong host advanced automation hubs specializing in SMT (Surface Mount Technology) production lines, reflow ovens, pick-and-place systems, and full-line integration solutions. These regions benefit from mature electronics supply chains, enabling rapid component sourcing and reduced assembly lead times. Zhejiang, particularly Wenzhou and Hangzhou, has emerged as a center for cost-optimized yet high-precision machinery, combining compact design engineering with scalable output.

Suppliers in these clusters operate within vertically integrated ecosystems, offering capabilities from CNC machining and motor integration to laser marking and fixture automation. This proximity to component suppliers and technical talent allows for faster prototyping cycles—typically 10–20 days for customized configurations—and shorter fulfillment windows of 30–45 days for standard orders. Buyers gain access to flexible MOQs (as low as 1 set), competitive pricing due to localized production, and robust customization options across machine type, feeder configuration, track length, and software compatibility.

How to Choose PCB Maker Machine Suppliers?

Selecting reliable partners requires systematic evaluation based on technical capability, operational performance, and transactional transparency:

Technical & Production Capabilities

Verify that suppliers offer proven expertise in core processes such as SMT placement accuracy, reflow soldering control, wave soldering integration, and automated optical inspection (AOI). Prioritize companies with documented R&D teams and in-house development of critical subsystems like vision alignment, nozzle arrays, and conveyor systems. Facility size is indicative of scalability—suppliers managing full production lines typically operate spaces exceeding 3,000m².

Quality and Compliance Verification

Confirm adherence to international standards including ISO 9001 for quality management and CE marking for electrical safety compliance. For buyers targeting EU or North American markets, ensure machines meet EMC and RoHS directives. Request test reports on placement speed, component recognition rates, and thermal profile stability in reflow systems.

Performance Metrics and Transaction Security

Analyze supplier performance indicators:

- On-time delivery rate ≥97% indicates reliable logistics execution

- Response time ≤4 hours ensures timely communication

- Reorder rate above 28% reflects customer satisfaction and product reliability

- Minimum online revenue of US $140,000+ suggests consistent market presence

Utilize secure payment mechanisms such as escrow services and insist on pre-shipment inspections. Sample testing should include benchmarking against IPC-610 standards for solder joint quality and evaluating uptime under continuous operation.

What Are the Best PCB Maker Machine Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Dongguan ICT Technology Co., Ltd. | Electronics Production Machinery, Reflow Soldering, SMT Solutions, Stencil Printers | Color, material, size, logo, packaging, panel graphics, wave soldering, reflow oven specs | 100% | 50% | ≤4h | $350,000+ | 1 set | N/A |

| Wenzhou Zhengbang Electronic Equipment Co., Ltd. | Pick-and-place machines, SMT assembly systems | PCB design, color, size, nozzles, capacitors, packaging, label, graphic options | 94% | <15% | ≤2h | $140,000+ | 1 piece/set | $1,849–4,800 |

| Morel Equipments Co., Ltd. | SMT pick-and-place, auto production lines, chip shooters, PLC-controlled systems | Machine type, track length, motors, fixtures, automation level, laser marking, nozzles | 100% | 50% | ≤1h | $820,000+ | 1 set | $9,999–100,000 |

| Zhejiang Neoden Technology Co., Ltd. | Automatic SMT lines, PCB assembly systems, pick-and-place units | Narrow electric/pneumatic feeders, fully automatic configurations | 97% | <15% | ≤4h | $170,000+ | 1 set | $2,899–14,999 |

| Dongguan Kingsun Automation Technology Co., Ltd. | Full-automatic SMT machines, high-speed pick-and-place, complete production lines | PCB size, color, material, weight, model, capacity, packaging, graphic specs | 100% | 28% | ≤2h | $10,000+ | 1 set | $4,200–104,676 |

Performance Analysis

Dongguan ICT Technology and Morel Equipments demonstrate strong reliability with 100% on-time delivery and reorder rates at 50%, indicating high buyer retention. Morel stands out with the highest reported online revenue ($820,000+) and offers premium equipment, including KE2080-compatible SMT systems and fully automated lines priced up to $100,000. Wenzhou Zhengbang provides entry-level pick-and-place machines starting below $2,000, making it ideal for startups or small workshops despite a lower reorder rate. Neoden balances affordability and functionality with modular SMT lines tailored for narrow-board applications. Dongguan Kingsun supports complex full-line deployments with customization depth across mechanical and software parameters, backed by flawless delivery performance.

FAQs

How to verify PCB maker machine supplier reliability?

Cross-validate certifications (ISO, CE) through official registries. Request facility audits via video tours focusing on CNC workshops, testing bays, and inventory management. Examine transaction histories for dispute resolution patterns and confirm after-sales support availability for installation and training.

What is the typical lead time for custom PCB machines?

Standard machines ship in 30–45 days. Customized systems involving modified track layouts, specialized feeders, or integrated AOI require 50–70 days, including validation and factory acceptance tests.

Do suppliers support global shipping and customs clearance?

Yes, experienced exporters provide FOB, CIF, and DAP shipping terms. They prepare essential documentation—commercial invoices, packing lists, bill of lading, and CE certificates—for smooth customs processing in destination countries.

Are samples available before bulk orders?

Most suppliers offer functional demos or trial runs via remote connection. Physical samples are rare due to machine size but may be arranged for critical subsystems like feeder modules or control panels at partial cost recovery.

What customization options are commonly offered?

Key configurable parameters include PCB dimensions (up to 500x500mm), placement speed (4,000–80,000 CPH), feeder types (8mm–104mm), vision system resolution, software interface language, and branding elements such as color scheme and logo engraving.