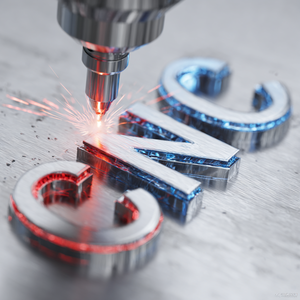

Custom Cnc Machining Near Me

Top sponsor listing

Top sponsor listing

About custom cnc machining near me

Where to Find Custom CNC Machining Suppliers?

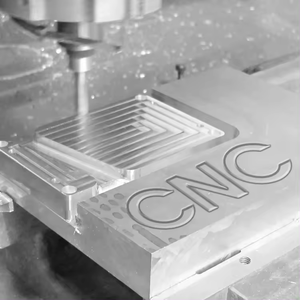

China remains a global leader in precision custom CNC machining, with key manufacturing clusters concentrated in Guangdong and Jiangsu provinces. These regions host vertically integrated supply chains that combine raw material sourcing, multi-axis machining, and surface treatment capabilities within compact industrial zones. Zhuhai, Huizhou, and Shanghai are emerging as hubs for high-mix, low-volume production, offering rapid prototyping and small-batch customization with lead times averaging 10–20 days.

The proximity of component suppliers, tooling workshops, and logistics networks enables efficient coordination for just-in-time deliveries. Buyers benefit from localized ecosystems where secondary operations—such as anodizing, laser engraving, and die casting—are available within 50 km. Cost advantages range from 25% to 40% compared to domestic Western suppliers, particularly for aluminum, stainless steel (e.g., SS304), and alloy-based parts. Scalability is supported through automated CNC lathes and 5-axis milling centers capable of handling both single-piece prototypes and mid-volume runs exceeding 10,000 units.

How to Choose Custom CNC Machining Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities Verification

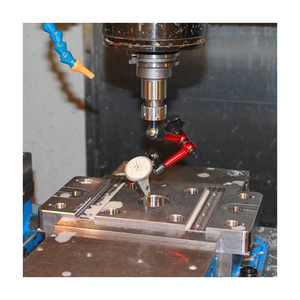

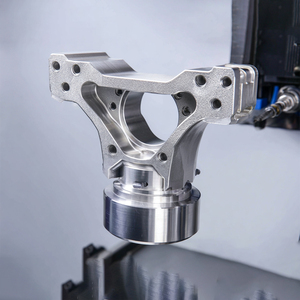

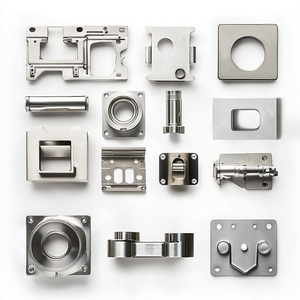

Confirm access to multi-axis CNC machines (3-axis, 4-axis, or 5-axis) and turning centers suitable for complex geometries. Review product listings for evidence of drawing-based manufacturing, tolerance control (typically ±0.005 mm), and support for customer-provided CAD/CAM files. Suppliers offering mold making, sheet metal fabrication, or casting services indicate broader engineering integration.

Production & Quality Metrics

Assess performance indicators including on-time delivery rate (target ≥95%), response time (ideally ≤2 hours), and reorder rates as proxies for customer satisfaction. Prioritize suppliers with documented quality management systems, even if formal ISO certification is not listed. Inquire about in-process inspection protocols, first-article reporting, and packaging standards to prevent transit damage.

- Minimum viable facility should support batch processing with MOQs starting at 1–5 pieces

- Customization scope must include material grade, dimensional accuracy, surface finish (e.g., polishing, oxidation), and branding (logo, label, silk print)

- Digital communication channels enabling real-time updates on work-in-progress

Transaction Risk Mitigation

Leverage secure payment frameworks where funds are released upon confirmation of order fulfillment. Evaluate online revenue trends and transaction volume as indirect indicators of market acceptance. Request physical or digital samples before scaling orders, especially when specifying non-standard materials or tight tolerances. Clarify revision policies for design adjustments during production.

What Are the Best Custom CNC Machining Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Huizhou Jiyan Hardware Co., Ltd. | Machining Services (1,793) | 100% | ≤1h | 21% | $40,000+ | Material, size, drawing, logo, packaging, label, graphic, dimensions | 1 pc | $0.50–3.89 |

| YAOPENG METAL PRODUCTS CO., LIMITED | CNC Machined Components | 100% | ≤2h | 20% | $40,000+ | Color, material, size, logo, label, drawing, heat sinks, die casting, polishing | 1 pc | $0.31–1.36 |

| Shanghai Yongzhen Machine Components Co., Ltd. | Machining Services | 95% | ≤3h | <15% | $20,000+ | Color, material, size, drawing, logo, packaging, SS304 compatibility | 50 pcs | $2–25 |

| SkyReach Intelligent MFG Limited | CNC Metal Parts | 87% | ≤3h | 15% | $30,000+ | Color, material, size, logo, packaging, label, graphic | 1 pc | $0.50–3.89 |

| Zhuhai Mingjiang Machinery Technology Co., Ltd. | Machining Services (83) | 100% | ≤13h | - | - | Material, size, drawing, logo, packaging | 5 pcs | $0.30–5.00 |

Performance Analysis

Huizhou Jiyan and YAOPENG stand out for responsiveness and customization breadth, both achieving 100% on-time delivery with sub-2-hour average response times and strong reorder activity. Their low MOQs and competitive pricing make them ideal for prototyping and small-series production. Shanghai Yongzhen serves higher-volume needs with tighter process controls but requires larger minimum batches (50+ units), suggesting optimization for serial manufacturing over one-off jobs.

SkyReach offers flexible entry-level pricing but exhibits lower delivery reliability (87%), indicating potential bottlenecks during peak demand. Zhuhai Mingjiang demonstrates perfect punctuality yet lacks reorder data and has slower communication cycles, which may affect collaboration efficiency. Buyers seeking rapid iteration should prioritize suppliers with 1-piece MOQs and comprehensive digital drawing support, while those focused on cost-per-unit reduction should negotiate tiered pricing at volumes above 1,000 units.

FAQs

How to verify custom CNC machining supplier reliability?

Cross-check delivery performance and response metrics against actual transaction history. Request sample parts to evaluate dimensional accuracy and surface finish consistency. Confirm whether revisions are permitted post-initial run and how design changes are documented and approved.

What is the typical lead time for custom CNC machined parts?

Standard lead times range from 10 to 20 days, including production and pre-shipment inspection. Prototypes can be delivered in 5–7 days if expedited services are available. Add 7–14 days for international air freight depending on destination.

Can I customize material type and surface treatment?

Yes, most suppliers support aluminum, brass, stainless steel (including SS304), and engineering plastics. Surface options include anodizing, plating, brushing, polishing, and laser marking. Specify requirements via technical drawings or reference samples.

Do suppliers accept single-piece orders?

Several top-tier suppliers, including Huizhou Jiyan and SkyReach, offer 1-piece minimum order quantities, making them suitable for prototyping and testing. However, unit costs decrease significantly at 100+ piece volumes due to setup amortization.

How are design files handled during production?

Reputable suppliers use encrypted file transfer systems and sign NDAs upon request. Ensure your CAD models (in STEP, DWG, or IGES formats) include geometric tolerances, material specifications, and inspection points to avoid misinterpretation.