Custom Cnc Machining

Top sponsor listing

Top sponsor listing

CN

CN

About custom cnc machining

Where to Find Custom CNC Machining Suppliers?

China remains the global epicenter for custom CNC machining services, with concentrated manufacturing hubs in Guangdong and Fujian provinces offering robust infrastructure and technical specialization. Shenzhen, a key industrial city in Guangdong, hosts numerous precision engineering firms equipped with multi-axis CNC systems, enabling high-complexity part production across aerospace, medical, and automotive sectors. Xiamen in Fujian has emerged as a center for integrated manufacturing, combining CNC machining with casting, sheet metal fabrication, and mold development under one supply chain.

These clusters benefit from vertically integrated ecosystems—where raw material sourcing, secondary processing, and logistics are co-located within 50km radii—reducing lead times by up to 30%. Suppliers in these regions typically offer MOQs starting from 1 piece, with average lead times ranging from 15–25 days for standard orders. Cost advantages remain significant, with per-unit production costs 20–40% lower than domestic Western suppliers due to optimized labor efficiency and localized material access.

How to Choose Custom CNC Machining Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, quality assurance, and transaction reliability.

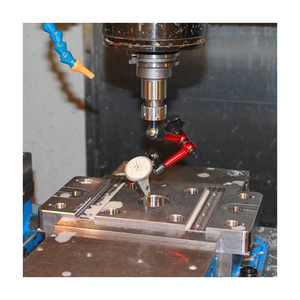

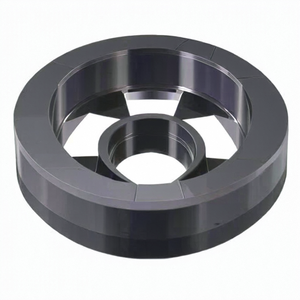

Technical & Production Capabilities

Verify that suppliers possess in-house CNC milling, turning, and 5-axis machining resources. Key indicators include support for materials such as stainless steel (e.g., SS304), aluminum, brass, and engineering plastics. Confirm compatibility with design inputs including 2D drawings, 3D CAD models, and GD&T specifications. Suppliers with additional capabilities in die casting, injection molding, or sheet metal fabrication offer greater flexibility for complex assemblies.

Quality Management Systems

While formal certifications (e.g., ISO 9001) are not explicitly listed in available data, prioritize suppliers demonstrating consistent on-time delivery performance (≥98%) and documented quality control processes. Reorder rates above 35% indicate customer satisfaction with dimensional accuracy, surface finish consistency, and adherence to tolerances (typically ±0.005mm).

- Minimum response time ≤3 hours for technical inquiries

- On-time delivery rate >95%

- Reorder rate exceeding 35% as proxy for service reliability

- In-house capacity for packaging, labeling, stamping, and logo application

Transaction and Risk Mitigation

Utilize secure payment mechanisms and request sample validation before scaling orders. Evaluate supplier responsiveness and communication clarity during initial engagement. Analyze product listings for granularity in pricing structure ($0.05–$15 range observed) and minimum order requirements—some suppliers accept single-piece orders, ideal for prototyping and low-volume testing.

What Are the Best Custom CNC Machining Suppliers?

| Company Name | Location | Verified Type | Main Services | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Xiamen Dazao Machinery Co., Ltd. | Fujian, CN | Custom Manufacturer | Machining, Casting, Moulds, Medical Plastic, Sheet Metal | US $280,000+ | 100% | ≤3h | 15% | 50–100 pcs |

| Shanghai Yongzhen Machine Components Co., Ltd. | Shanghai, CN | Multispecialty Supplier | Machining, Metal Parts, Drawing-Based Customization | US $20,000+ | 95% | ≤3h | <15% | 50–100 pcs |

| Shenzhen Benxin Electronic Hardware Co., Ltd. | Guangdong, CN | Not Specified | Machining, Stainless Steel Pipes, Sheet Metal | US $8,000+ | 100% | ≤12h | 50% | 1 pc |

| Shenzhen Xijiu Technology Co., Ltd. | Guangdong, CN | Not Specified | Machining, Sheet Metal, Moulds, Plastic Products | US $40,000+ | 100% | ≤1h | 40% | 1–2 pcs |

| Shenzhen Xiehongxin Precision Technology Co., Ltd. | Guangdong, CN | Multispecialty Supplier | Precision CNC Machining, Custom Metal Parts | US $60,000+ | 100% | ≤3h | 35% | 10 pcs |

Performance Analysis

Shenzhen-based suppliers dominate in reorder performance and responsiveness: Shenzhen Benxin leads with a 50% reorder rate despite lower revenue volume, indicating strong client retention likely driven by low MOQs (1 piece) and competitive pricing ($0.05–$0.10/unit). Shenzhen Xijiu Technology stands out for rapid communication (≤1h response) and broad customization scope across materials, finishes, and branding options. Xiamen Dazao Machinery demonstrates highest revenue output and diversified production lines, making it suitable for large-scale, multi-process projects. Shanghai Yongzhen, while reliable in delivery (95%), shows lower reorder activity, suggesting room for improvement in post-sale satisfaction or cost competitiveness.

FAQs

How to verify custom CNC machining supplier reliability?

Assess on-time delivery history, reorder rates, and response times as proxies for operational stability. Request evidence of in-house equipment via facility videos or photo documentation. Validate technical alignment through prototype submissions based on your design files.

What is the typical sampling timeline for CNC machined parts?

Standard prototypes take 7–14 days to produce, depending on complexity and material availability. Add 5–10 days for international air shipping. For 5-axis or tight-tolerance components, allow up to 21 days for machining and inspection.

Can suppliers handle global shipping and export compliance?

Yes, most established suppliers manage export logistics, including customs documentation and INCOTERMS negotiation (FOB, CIF). Confirm whether they support your preferred freight method and destination-region regulatory standards.

Do custom CNC machining suppliers accept small-batch or single-unit orders?

Many do—particularly those in Shenzhen. Several suppliers list minimum orders of 1 piece, catering to R&D teams, startups, and niche manufacturers requiring functional prototypes or limited-run components.

How to initiate a customization request effectively?

Provide detailed technical packages including material specifications, dimensional drawings, surface finish requirements (e.g., anodizing, plating), and any required certifications. Clear communication of application context (e.g., medical, automotive) helps suppliers recommend optimal process parameters.