Custom Cnc Machining Factory

1/28

1/28

1/19

1/19

1/32

1/32

1/30

1/30

CN

CN

1/18

1/18

1/9

1/9

CN

CN

1/34

1/34

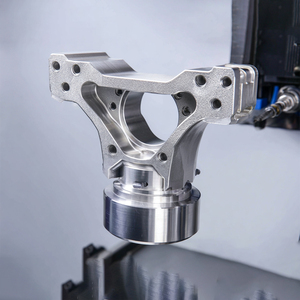

About custom cnc machining factory

Where to Find Custom CNC Machining Factory Suppliers?

China remains the global epicenter for custom CNC machining services, with concentrated manufacturing hubs in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated factories equipped with multi-axis CNC milling, turning, and grinding centers, enabling end-to-end production from prototype to mass batch runs. Guangdong—particularly Shenzhen and Dongguan—accounts for over 40% of China’s precision machining output, supported by mature supply chains for aluminum, stainless steel, brass, and engineering plastics.

The industrial clusters offer scalable production capacity, with many facilities operating 24/7 shifts and maintaining in-house tooling, quality inspection, and surface treatment capabilities. Buyers benefit from localized ecosystems where raw material sourcing, secondary processing (e.g., anodizing, plating), and logistics are streamlined within 50-kilometer radii. This integration reduces lead times by 25–35% compared to offshore alternatives and supports MOQs as low as one piece for prototyping, scaling to tens of thousands for serial production.

How to Choose a Custom CNC Machining Factory?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Production & Technical Capabilities

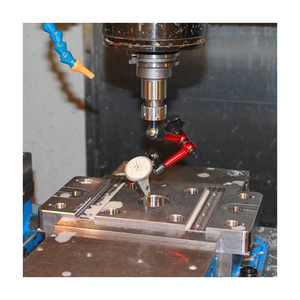

Confirm access to advanced equipment such as 5-axis CNC machines, Swiss lathes, and automated CMM (Coordinate Measuring Machine) inspection systems. Prioritize suppliers with documented in-house production lines capable of handling tight tolerances (±0.005 mm) and complex geometries. Evidence of multi-process integration—including sheet metal fabrication, gear hobbing, and assembly—indicates higher value-add potential.

Quality Assurance Systems

While formal ISO 9001 certification is not explicitly stated in all cases, consistent on-time delivery rates above 95% and verifiable response times suggest disciplined internal processes. Look for suppliers offering precision packaging, labeling, stamping, and drawing validation as part of standard workflow—indicators of structured quality control protocols.

Customization Flexibility and Responsiveness

Evaluate customization scope across material selection, surface finishes, color coding, logo engraving, and dimensional adjustments. Response time is a critical performance metric: suppliers responding within ≤1 hour demonstrate operational agility. Cross-reference this with reorder rates—those exceeding 25% indicate customer satisfaction and service consistency.

Transaction Reliability Indicators

Use quantifiable metrics to assess reliability:

- On-time delivery rate ≥96%

- Average response time ≤2 hours

- Reorder rate >25% preferred

- Verifiable online revenue (US $100,000+ annual indicates established operations)

Suppliers offering instant quoting tools and accepting single-piece orders often leverage digital manufacturing platforms to reduce setup costs and accelerate turnaround.

What Are the Top Custom CNC Machining Factories?

| Company Name | Specialization | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Hk Aa Industrial Co., Limited | Multispecialty Machining | Multispecialty Supplier | US $140,000+ | 92% | ≤2h | <15% | 1–100 pcs | $1–50 |

| Dongguan Senyuan Hardware Co., Ltd. | Aluminum & Stainless Steel Components | Not Specified | US $180,000+ | 100% | ≤1h | 27% | 5 pcs | $0.52–2.68 |

| SkyReach Intelligent MFG Limited | Mass Production & Instant Quoting | Custom Manufacturer | US $20,000+ | 84% | ≤4h | <15% | 1 pc | $0.50–3.89 |

| Perfect Goods Prototype Co., Ltd. | 5-Axis Milling & Rapid Prototyping | Custom Manufacturer | US $560,000+ | 96% | ≤3h | 26% | 1 pc | $0.10–4.18 |

| Shenzhen Xijiu Technology Co., Ltd. | CNC Milling/Turning & Sheet Metal | Not Specified | US $40,000+ | 100% | ≤1h | 33% | 1 pc | $0.11–1.11 |

Performance Analysis

Dongguan Senyuan and Shenzhen Xijiu stand out for responsiveness (≤1h) and perfect on-time delivery records, making them suitable for urgent or recurring orders. Shenzhen Xijiu offers the lowest price range ($0.11–1.11) with high reorder frequency (33%), indicating strong buyer retention. Perfect Goods Prototype leads in scale and technological breadth, backed by US $560,000+ in verified revenue and support for single-piece prototyping at competitive rates. Hk Aa Industrial serves broader applications but has a lower reorder rate (<15%), suggesting room for improvement in long-term client engagement. SkyReach provides flexible entry points (1-piece MOQ) but lags in delivery consistency (84%) and response speed (≤4h).

FAQs

What materials do custom CNC machining factories typically work with?

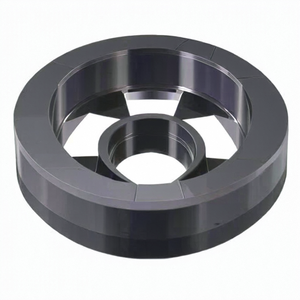

Common materials include aluminum alloys (6061, 7075), stainless steel (304, 316), carbon steel, brass, copper, titanium, and engineering plastics like POM (Delrin), PEEK, and nylon. Most suppliers list material compatibility in product specifications and support custom sourcing upon request.

What is the typical lead time for CNC machined parts?

Prototype orders generally take 5–10 days, while bulk production runs (1,000+ units) require 15–25 days depending on complexity and finishing requirements. Express services may reduce timelines by 30–50% with expedited fees.

Can I request customized finishes and branding?

Yes, most factories offer surface treatments such as anodizing, powder coating, passivation, polishing, and plating. Logo engraving, laser marking, label application, and custom packaging are widely available across the listed suppliers.

Do these factories support international shipping and documentation?

All listed suppliers have demonstrated export activity through online transaction histories. They typically provide commercial invoices, packing lists, and bill of lading support. Buyers should confirm compliance with destination-country import regulations, especially for regulated industries like medical or aerospace.

How can I verify a factory's production claims?

Request facility videos, machine lists, or third-party audit reports. Conduct virtual audits via live video calls to inspect CNC workcells, quality inspection stations, and inventory management practices. Verified order history and consistent response behavior serve as indirect indicators of operational transparency.