Cnc Precision Machining Factory

HK

HK

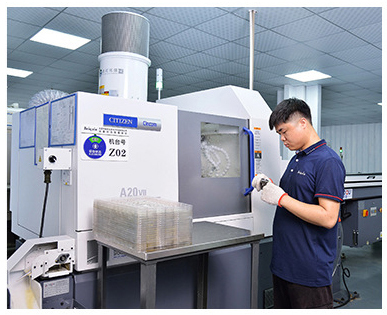

About cnc precision machining factory

Where to Find CNC Precision Machining Factory Suppliers?

China remains the global epicenter for precision CNC machining services, with key manufacturing clusters concentrated in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated facilities equipped with multi-axis CNC milling, turning, grinding, and EDM capabilities, enabling high-accuracy production across aerospace, automotive, medical, and industrial automation sectors. The proximity of raw material suppliers, surface treatment providers, and logistics networks reduces component lead times by 25–40% compared to offshore alternatives.

Suppliers in these hubs operate dedicated production lines with average facility sizes exceeding 3,000m², supporting both rapid prototyping and mass production. Many maintain in-house tooling, casting, sheet metal fabrication, and additive manufacturing units, allowing end-to-end control over complex part manufacturing. This integration enables MOQs as low as 1 piece for prototypes and scalable runs up to hundreds of thousands annually, with typical delivery cycles ranging from 7–25 days depending on complexity and finishing requirements.

How to Choose CNC Precision Machining Factory Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Prioritize suppliers holding ISO 9001 certification as a baseline for documented quality management systems. For regulated industries (e.g., medical, aerospace), confirm adherence to AS9100, IATF 16949, or FDA standards where applicable. Request inspection reports including CMM (Coordinate Measuring Machine) data, first-article inspections (FAI), and material certifications (e.g., mill test reports).

Production Capability Assessment

Evaluate core competencies through the following criteria:

- Ownership of multi-axis CNC machines (3-axis, 4-axis, 5-axis) and automated workholding systems

- In-house secondary processes: anodizing, plating, heat treatment, welding, laser marking

- Support for diverse materials: aluminum alloys (6061, 7075), stainless steel (303, 304, 316), titanium, brass, PEEK, Delrin

- Demonstrated tolerance capabilities down to ±0.005 mm for critical features

Cross-reference machine ownership claims with on-time delivery performance and response times to assess operational reliability.

Transaction Security & Communication Efficiency

Favor suppliers with verified response times under 4 hours and reorder rates above 20%, indicating customer satisfaction. Utilize secure payment mechanisms such as escrow services for initial orders. Conduct virtual factory audits via video tours to verify equipment ownership and workflow organization before committing to large-volume contracts.

What Are the Best CNC Precision Machining Factory Suppliers?

| Company Name | Verification Status | Main Services | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| SkyReach Intelligent MFG Limited | Custom Manufacturer | CNC Milling/Turning, Rapid Prototyping, Metal Fabrication | 88% | ≤3h | 20% | US $30,000+ | Color, material, size, logo, packaging, graphic |

| Industrial Man Manufacturing Co., Limited | Custom Manufacturer | 5-Axis CNC, Stamping, Vacuum Casting, Sheet Metal | 100% | ≤4h | 22% | US $20,000+ | Design, labeling, hybrid molding, surface finish, STL file support |

| Bozhan Precision Hardware INC | Not specified | Sheet Metal Fabrication, Machining, Casting, Forging | - | ≤2h | - | - | Limited public data |

| Ald Precision Manufacturing Co., Ltd. | Not specified | Machining, Casting, Moulds, Sheet Metal, Other Fabrication | 100% | ≤1h | - | US $1,000+ | Standard industrial customization |

| PHUC HAI COMPANY | Not specified | CNC Lathe, Shafts, Plastic & Ceramic Components | 100% | ≤7h | - | US $4,000+ | High-volume OEM configurations |

Performance Analysis

Industrial Man Manufacturing and Ald Precision demonstrate strong operational discipline with 100% on-time delivery and sub-4-hour response times, making them suitable for time-sensitive projects. SkyReach offers competitive pricing starting at $0.48/unit with flexible MOQs (1 pc), ideal for prototyping and low-volume production. Bozhan and PHUC HAI target higher-volume runs with minimum orders of 10–10,000 pieces, reflecting specialization in serial manufacturing. Buyers seeking full-service capabilities should prioritize suppliers offering integrated sheet metal, casting, and surface treatment options to reduce supply chain fragmentation.

FAQs

How to verify CNC machining supplier capabilities?

Request evidence of owned equipment through facility videos or photo documentation. Confirm processing tolerances, supported file formats (STEP, IGES, DWG), and inspection protocols. Validate certifications by checking issuing body databases and review transaction histories for consistency in order fulfillment.

What is the typical lead time for custom CNC parts?

Standard lead times range from 7–15 days for machined prototypes and 15–25 days for production batches, excluding shipping. Complex geometries requiring secondary operations may extend timelines by 5–10 days. Express services are available from select suppliers at a premium.

Can CNC machining factories handle small batch orders?

Yes, most suppliers accommodate MOQs of 1–10 pieces for prototyping and bridge production. Unit costs decrease significantly at volumes exceeding 500 units due to setup amortization. Confirm scalability before transitioning from prototype to mass production.

Do suppliers provide design for manufacturability (DFM) feedback?

Reputable manufacturers offer free DFM analysis to optimize part geometry, reduce machining time, and improve yield. Submit 3D models early in the sourcing process to receive actionable recommendations on wall thickness, tolerancing, and feature simplification.

Are surface treatments included in CNC machining services?

Most factories provide post-processing options such as anodizing (Type II/III), electroplating, powder coating, passivation, and brushing. Specify finish requirements in RFQs to ensure accurate quoting and compliance with environmental standards like RoHS or REACH.