Precision Cnc Machining Services Factory

1/21

1/21

1/21

1/21

HK

HK

CN

CN

1/18

1/18

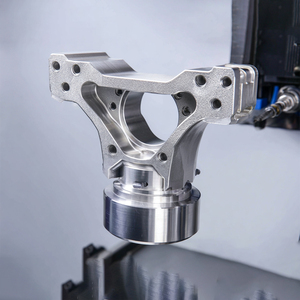

About precision cnc machining services factory

Where to Find Precision CNC Machining Services Factory Suppliers?

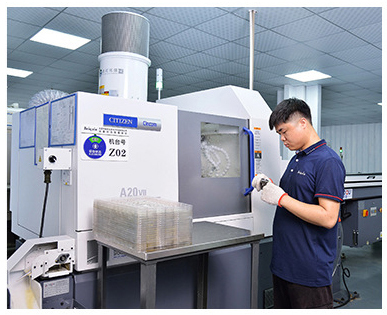

China remains the global epicenter for precision CNC machining services, with key manufacturing clusters concentrated in Guangdong and Zhejiang provinces. These regions host vertically integrated factories equipped with multi-axis CNC lathes, milling centers, and automated production lines capable of delivering tight-tolerance components (±0.005 mm) across aerospace, medical, automotive, and industrial equipment sectors. Dongguan, Huizhou, and Huzhou feature dense ecosystems of certified precision manufacturers, supported by localized supply chains for raw materials such as aluminum 6061/7075, stainless steel 303/316, titanium, and engineering plastics.

The industrial maturity in these zones enables scalable production from rapid prototyping to high-volume runs exceeding 100,000 units monthly. Factories leverage in-house tooling, CAD/CAM programming, and quality inspection labs—reducing dependency on external vendors. This integration translates into lead times averaging 10–20 days for custom parts, with some suppliers offering instant online quoting systems for faster turnaround. Cost efficiency is further enhanced by lower labor and operational expenses compared to North American or European facilities, typically yielding 30–50% savings on comparable precision work.

How to Choose Precision CNC Machining Services Factory Suppliers?

Selecting a reliable partner requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Confirm adherence to internationally recognized standards such as ISO 9001:2015 for quality management. For regulated industries (e.g., medical, aerospace), request evidence of additional certifications including ISO 13485, AS9100, or RoHS compliance. Review available inspection reports, first-article testing (FAI), and use of metrology tools like CMM (Coordinate Measuring Machines), optical comparators, and surface roughness testers.

Production Infrastructure Assessment

Evaluate core capabilities through verifiable indicators:

- Ownership of 4-axis and 5-axis CNC machines for complex geometries

- In-house secondary operations: anodizing, plating, welding, heat treatment, laser marking

- Digital workflow integration: CAM software (e.g., Mastercam, SolidWorks), ERP systems

- Minimum facility size exceeding 2,000m² to support batch processing and lean manufacturing

Cross-reference stated capacities with performance metrics such as on-time delivery rates (>90% recommended) and reorder frequency, which reflect operational reliability.

Sourcing & Transaction Risk Mitigation

Utilize secure payment mechanisms that align with order scale—T/T deposits for initial trials, with escrow-backed transactions for larger volumes. Prioritize suppliers with documented export experience to your target market, ensuring packaging, labeling, and documentation meet regional regulatory requirements. Request physical or digital samples before full-scale production to validate dimensional accuracy and surface finish.

What Are the Best Precision CNC Machining Services Factory Suppliers?

| Company Name | Location | Main Products | MOQ | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Verified Specialty |

|---|---|---|---|---|---|---|---|---|

| Dongguan Shufengyuan Precision Manufacturing Co., Ltd. | Guangdong, CN | Machining Services | 1 dozen | $0.99–4.98 | 100% | ≤2h | - | Custom Manufacturer |

| Bozhan Precision Hardware INC | Guangdong, CN | Sheet Metal Fabrication, Machining, Casting, Forging | 10 pieces | $0.49–4.49 | - | ≤2h | - | Multi-process Integration |

| SkyReach Intelligent MFG Limited | Guangdong, CN | Customization-focused Machining | 1 piece | $0.10–3.89 | 76% | ≤3h | 15% | Custom Manufacturer |

| Huizhou Hongchuang Precision Machinery Co., Ltd. | Guangdong, CN | Machining Services, Screws, Valves | 1 piece | $0.10–0.70 | 83% | ≤3h | <15% | High-Volume Production |

| Huzhou Dear Industry Co., Ltd. | Zhejiang, CN | Precision CNC, Rapid Prototyping | 1 piece | $0.10–10.00 | 100% | ≤6h | 48% | Multispecialty Supplier |

Performance Analysis

Dongguan Shufengyuan and Huzhou Dear stand out with 100% on-time delivery records, indicating robust production planning and logistics execution. Huzhou Dear further demonstrates strong customer retention with a 48% reorder rate—suggesting consistent quality and service satisfaction. SkyReach and Huizhou Hongchuang offer ultra-low MOQs (down to 1 piece), ideal for prototyping and small-batch development, though their lower reorder rates may indicate variability in long-term performance. Bozhan’s broad service portfolio—including sheet metal, casting, and forging—positions it as a one-stop solution for multi-process projects. Response times across all suppliers are competitive, with three achieving sub-3-hour average replies, enabling agile communication for time-sensitive engineering adjustments.

FAQs

What materials can be processed by these CNC machining suppliers?

Commonly supported materials include aluminum alloys (6061, 7075), stainless steels (303, 304, 316), carbon steel, brass, copper, titanium, PEEK, Delrin, and polycarbonate. Most suppliers accommodate material sourcing either via customer-provided stock or procurement from certified mills.

What is the typical lead time for custom CNC machined parts?

Standard lead times range from 7 to 15 days after design approval. Expedited services are available at select facilities for urgent orders (5–7 days), particularly for single-axis turning or simple milling tasks. Complex 5-axis or multi-step assemblies may require up to 20 days.

Do these factories support design for manufacturability (DFM) feedback?

Yes, leading suppliers provide DFM analysis during quotation, identifying potential cost drivers, tolerance conflicts, or tool access issues. Some offer free design optimization suggestions to reduce cycle time and improve yield.

Can I request third-party inspections before shipment?

Absolutely. Reputable suppliers permit pre-shipment inspections by SGS, TÜV, Bureau Veritas, or other accredited agencies. Inspection protocols should cover dimensional verification, surface finish, material composition, and packaging integrity.

Are there options for post-processing and finishing?

Virtually all listed suppliers offer secondary operations including anodizing (Type II, Type III), passivation, powder coating, sandblasting, polishing, and engraving. Custom packaging and labeling—including anti-corrosion VCI bags—are also widely available.