Custom Cnc Milling Service

CN

CN

Top sponsor listing

Top sponsor listing

1/20

1/20

1/17

1/17

1/32

1/32

HK

HK

1/35

1/35

1/24

1/24

1/3

1/3

1/21

1/21

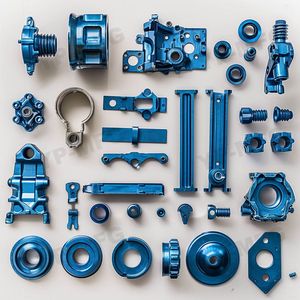

About custom cnc milling service

Where to Find Custom CNC Milling Service Suppliers?

China remains the global epicenter for precision machining services, with concentrated supplier clusters in Guangdong and Jiangsu provinces offering advanced manufacturing ecosystems. Shenzhen and Dongguan in Guangdong host over 70% of China’s high-precision CNC service providers, leveraging proximity to Tier-1 electronics and automotive industries. These regions benefit from mature supply chains for raw materials—particularly aluminum, stainless steel, and engineering plastics—reducing component lead times by 25–40% compared to offshore alternatives.

The industrial clusters support vertically integrated production networks, where material sourcing, multi-axis machining, surface treatment, and quality inspection occur within tightly coordinated zones. This integration enables rapid prototyping (typically 5–7 days) and scalable batch production with MOQs as low as 1 piece. Buyers gain access to facilities equipped with 3-, 4-, and 5-axis CNC systems, wire EDM, and automated inspection tools, ensuring tight tolerances (±0.005 mm) across complex geometries. Average production costs are 30–50% lower than domestic Western suppliers, driven by optimized labor efficiency and localized logistics.

How to Choose Custom CNC Milling Service Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical compliance, production reliability, and transaction security.

Technical and Process Verification

Confirm the supplier's capability to meet dimensional accuracy and surface finish requirements through documented quality control protocols. ISO 9001 certification is a baseline indicator of process standardization. For export-focused buyers, verify compliance with regional standards such as RoHS (electronics), AS9100 (aerospace), or FDA (medical components). Request evidence of metrology equipment usage—including CMM (Coordinate Measuring Machines) and optical comparators—for critical part validation.

Production Capacity Assessment

Evaluate key operational metrics:

- Minimum facility size of 2,000m² indicating investment in dedicated production lines

- In-house capabilities covering milling, turning, grinding, and post-processing (anodizing, plating, silk printing)

- Engineering team availability for DFM (Design for Manufacturability) feedback and drawing validation

Cross-reference online revenue indicators and on-time delivery rates (>95% recommended) to assess operational stability and order prioritization.

Transaction and Quality Safeguards

Utilize secure payment mechanisms that align financial release with verified delivery milestones. Prioritize suppliers with documented quality assurance processes, including first-article inspection reports and batch traceability. Prototype sampling is strongly advised—evaluate dimensional accuracy, material integrity, and surface treatment adherence before scaling to full production. Lead times for initial samples typically range from 7 to 14 days, depending on complexity.

What Are the Best Custom CNC Milling Service Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Verification Status |

|---|---|---|---|---|---|---|---|

| Shenzhen Xinbanghui Hardware Products Co., Ltd. | Machining Services | Color, material, size, logo, packaging, label, graphic | 100% | <15% | ≤4h | US $20,000+ | Custom Manufacturer |

| Dongguan Xie Lifeng Technology Co., Ltd. | Machining Services, Moulds, Sheet Metal Fabrication | N/A | 91% | 33% | ≤4h | US $50,000+ | Not Specified |

| YAOPENG METAL PRODUCTS CO., LIMITED | N/A | Silk print, color, oxidation, packaging, heat sinks, label, material, size, drawings, die casting, polishing, logo, graphic | 100% | 20% | ≤2h | US $40,000+ | Custom Manufacturer |

| Dongguan Senyuan Hardware Co., Ltd. | Machining Services | N/A | 100% | 27% | ≤2h | US $180,000+ | Not Specified |

| SkyReach Intelligent MFG Limited | N/A | Color, material, size, logo, packaging, label, graphic | 87% | 15% | ≤3h | US $30,000+ | Custom Manufacturer |

Performance Analysis

Suppliers like Dongguan Senyuan Hardware and YAOPENG Metal Products demonstrate strong operational discipline with 100% on-time delivery and sub-2-hour response times, making them suitable for time-sensitive projects. Senyuan stands out with the highest reported online revenue (US $180,000+), suggesting robust order volume and market trust. Dongguan Xie Lifeng Technology exhibits a high reorder rate (33%), indicating customer satisfaction despite a slightly lower on-time delivery performance (91%).

Manufacturers verified as "Custom Manufacturers" represent dedicated job shops with engineering capacity tailored for OEM/ODM work. Companies offering extensive customization options—including material selection, surface treatments, and branding—provide greater flexibility for specialized applications in medical, robotics, and consumer electronics sectors. Buyers should prioritize suppliers with documented post-processing capabilities (e.g., anodizing, passivation) when functional performance is critical.

FAQs

How to verify custom CNC milling service supplier reliability?

Validate certifications through official registries and request facility audit reports or video walkthroughs. Analyze transaction history metrics such as on-time delivery rate and response time. Review customer feedback focusing on design collaboration, tolerance adherence, and communication clarity during revisions.

What is the typical MOQ and pricing structure?

Most suppliers offer MOQs starting at 1 piece, with competitive pricing ranging from $0.10 to $3.89 per unit depending on complexity, material, and finishing requirements. High-volume orders (100+ units) often unlock incremental cost reductions of 15–25%.

What lead times should be expected?

Prototype lead times average 7–10 days. Production batches of 1,000 units typically require 15–25 days, including quality inspection and packaging. Expedited processing may reduce timelines by 3–5 days at additional cost.

Can suppliers handle full project lifecycle support?

Yes, leading providers offer end-to-end services—from CAD/CAM programming and DFM analysis to assembly and kitting. Confirm availability of technical engineers for pre-production consultation and revision management.

What materials and finishes are commonly supported?

Standard materials include 6061-T6 and 7075 aluminum, 303/304/316 stainless steel, brass, copper, and engineering plastics (POM, PEEK, ABS). Surface treatments encompass anodizing (Type II/III), electroplating, powder coating, sandblasting, and laser engraving.