Custom Embedded Electronics Manufacturer

Top sponsor listing

Top sponsor listing

1/29

1/29

1/3

1/3

1/20

1/20

1/3

1/3

1/3

1/3

1/24

1/24

1/3

1/3

1/21

1/21

0

0

1/26

1/26

1/3

1/3

1/3

1/3

1/3

1/3

1/28

1/28

1/3

1/3

1/9

1/9

1/3

1/3

About custom embedded electronics manufacturer

Where to Find Custom Embedded Electronics Manufacturers?

China remains the global epicenter for custom embedded electronics manufacturing, with Shenzhen and Dongguan serving as primary hubs due to their dense ecosystems of component suppliers, contract manufacturers, and R&D talent. These regions host vertically integrated facilities capable of delivering full-turnkey solutions—from PCB design and microcontroller programming to final assembly and testing—enabling rapid prototyping and scalable production.

The industrial clusters offer significant logistical and cost advantages, including access to Tier-1 semiconductor distributors, automated SMT lines, and compliant testing labs within a 20km radius. This proximity reduces lead times by up to 40% compared to offshore alternatives and supports agile iteration for complex embedded systems in automotive, IoT, and industrial automation applications. Buyers benefit from flexible MOQs, with many manufacturers accommodating prototype runs of 1–5 units before scaling to mass production.

How to Choose a Custom Embedded Electronics Manufacturer?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

Design & Engineering Capability

Verify proven experience in firmware development, circuit design, and signal integrity analysis. Look for suppliers offering schematic capture, PCB layout (including HDI and multilayer boards), and embedded software integration (C/C++, RTOS, or FreeRTOS). Evidence of prior work on sensor fusion, wireless modules (Wi-Fi/Bluetooth/NB-IoT), or automotive-grade systems indicates higher technical maturity.

Production Infrastructure

Assess key indicators of manufacturing robustness:

- In-house SMT and DIP assembly lines with automated optical inspection (AOI) and X-ray testing

- Support for RoHS-compliant reflow and wave soldering processes

- Own PCB fabrication capability or established partnerships with certified board houses

Cross-reference facility claims with on-time delivery performance (target ≥90%) and reorder rates as proxies for customer satisfaction and process reliability.

Quality Assurance & Compliance

Demand adherence to IPC-A-610 Class 2 standards for electronic assemblies. For regulated industries (medical, automotive, industrial), confirm compliance with ISO 13485, IATF 16949, or CE/FCC/RoHS directives. Request test reports such as ICT (In-Circuit Test), functional testing protocols, and environmental stress screening data. Suppliers providing customization options (material, color, labeling, packaging) typically demonstrate stronger quality control systems tailored to client-specific requirements.

Transaction Risk Mitigation

Prioritize suppliers with verifiable online transaction histories and responsive communication (response time ≤2 hours is ideal). Use secure payment mechanisms and require sample validation before bulk orders. Evaluate firmware protection policies and IP confidentiality agreements, especially when sharing proprietary code or hardware designs.

What Are the Top Custom Embedded Electronics Manufacturers?

| Company Name | Location | Main Products | Customization Services | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Product Examples |

|---|---|---|---|---|---|---|---|---|

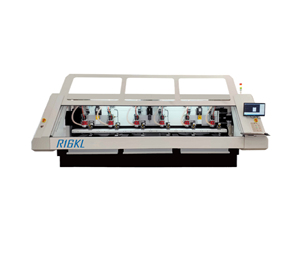

| Dongguan Kexin Electron Co., Ltd. | Dongguan, CN | Electronics Production Machinery (233); Machine Tool Accessories (317) | Yes – own production line, customization services | 91% | ≤5h | 24% | US $50,000+ | N/A |

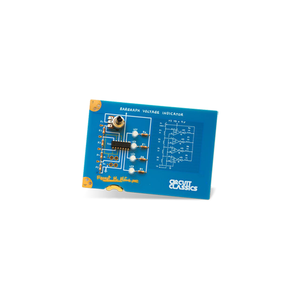

| Shenzhen Sinosky Electronics Co., Ltd. | Shenzhen, CN | Embedded Microcontrollers, Single-Chip Solutions | Yes – color, material, size, logo, packaging, graphic | 90% | ≤2h | 27% | US $300,000+ | Microcontroller Module ($5.70, MOQ: 5) |

| Shenzhen Yixing Micro Technology Co., Ltd. | Shenzhen, CN | ICs (2,777); Microcontrollers & FPGAs (96); Development Kits (56) | Limited – focus on standard IC/components | 100% | ≤1h | 17% | US $190,000+ | IC Chips ($0.10–0.90, MOQ: 1) |

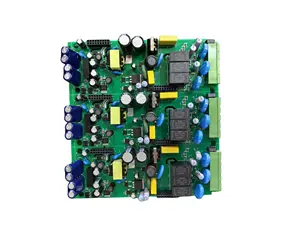

| Toptek Pcb Co., Limited | China | Custom Multilayer HDI & Automotive PCBs | Yes – full turnkey PCB/PCBA services | 100% | ≤2h | 100% | US $1,000+ | HDI Automotive PCB ($1–1.20, MOQ: 1) |

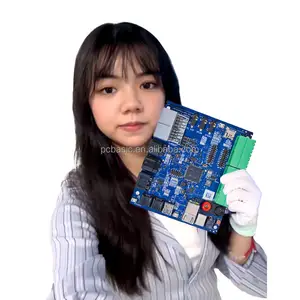

| INTELLISENSE TECHNOLOGY | China | PCBA (1,105); Software; Industrial Automation Systems | Yes – embedded development, AI, multi-sensor systems | - | ≤5h | - | - | ESP32 Industrial Solution ($199–499, MOQ: 199) |

Performance Analysis

Shenzhen-based Sinosky Electronics stands out for high-volume transaction volume (US $300,000+) and comprehensive customization, making it suitable for OEMs requiring branded, application-specific modules. Toptek PCB demonstrates exceptional reliability with a 100% on-time delivery and reorder rate, indicating strong customer retention despite lower reported revenue—ideal for mission-critical PCB/PCBA projects. Yixing Micro Technology excels in component-level supply with sub-hour response times and vast IC inventory, though its role is more distributor than full-system developer. INTELLISENSE TECHNOLOGY targets high-end embedded development, particularly in AI and predictive systems, but lacks verified performance metrics, warranting deeper due diligence. Dongguan Kexin offers moderate scalability with consistent fulfillment and diversified machinery expertise that may support hybrid electro-mechanical product integration.

FAQs

What is the typical MOQ for custom embedded electronics?

MOQ varies by complexity and supplier. Prototype orders start at 1–5 units, especially for bare PCBs or pre-programmed ICs. Functional assemblies typically require 10–100 units. High-complexity systems (e.g., multi-sensor AI devices) may have MOQs exceeding 100 units. Always confirm scalability from prototype to volume production.

How long does it take to receive custom embedded electronics?

Lead times range from 7–15 days for simple PCBA prototypes to 3–6 weeks for fully assembled, tested systems requiring firmware development and certification. Additional time should be allocated for shipping (5–10 days via express air) and customs clearance.

Can manufacturers handle both hardware and software development?

Some suppliers, like INTELLISENSE TECHNOLOGY and Sinosky Electronics, offer co-development services including firmware coding, driver integration, and UI/UX for connected devices. Confirm scope through technical documentation review and request access to past project portfolios or GitHub repositories if available.

Do embedded electronics manufacturers provide testing and certification support?

Leading suppliers conduct in-house functional, burn-in, and environmental testing. For export markets, verify whether they assist with CE, FCC, or RoHS compliance testing through accredited third-party labs. Ask for test reports and failure rate statistics (e.g., PPM levels).

How can I protect my intellectual property when sourcing custom electronics?

Establish a mutual NDA before sharing schematics or code. Choose manufacturers with documented IP protection policies and avoid suppliers who reuse client designs. Ensure firmware is delivered encrypted or programmed at the end of the line, and consider using locked-down microcontrollers to prevent reverse engineering.