Custom Made Electronics

Top sponsor listing

Top sponsor listing

1/5

1/5

1/34

1/34

1/22

1/22

1/21

1/21

1/61

1/61

1/20

1/20

1/34

1/34

CN

CN

1/20

1/20

About custom made electronics

Where to Find Custom Made Electronics Suppliers?

China remains the global epicenter for custom electronics manufacturing, with Shenzhen and Suzhou emerging as key hubs due to concentrated expertise in PCB design, SMT assembly, and rapid prototyping. Shenzhen’s ecosystem supports high-mix, low-volume production ideal for customized electronic components, leveraging proximity to semiconductor suppliers and contract manufacturers. Suzhou’s industrial parks host advanced surface-mount technology (SMT) lines and automated optical inspection (AOI) systems, enabling precision assembly for mission-critical applications.

These regions benefit from vertically integrated supply chains—encompassing PCB fabrication, component sourcing, firmware programming, and final testing—reducing lead times by 20–35% compared to offshore alternatives. Buyers gain access to agile manufacturers capable of fulfilling orders from one piece to high-volume batches, supported by responsive engineering teams and digital design validation tools such as Gerber file review and 3D modeling. Typical advantages include MOQs as low as 1 unit, per-unit pricing starting below $0.30 for assembled PCBA, and average response times under 3 hours.

How to Choose Custom Made Electronics Suppliers?

Evaluate suppliers using the following criteria to ensure technical reliability and operational efficiency:

Design & Engineering Capabilities

Confirm support for full-cycle development: schematic capture, PCB layout, component sourcing, and prototype validation. Prioritize suppliers offering 3D previews, Gerber file analysis, and in-house PCB assembly. Evidence of dedicated R&D teams—reflected in customization tags such as "PCBA assembly" or "engineering design"—indicates stronger technical capacity.

Production Infrastructure Verification

Assess core manufacturing competencies through objective indicators:

- In-house SMT and DIP production lines with automated pick-and-place machines

- Comprehensive testing protocols including ICT, AOI, and functional testing

- Support for multiple packaging options, labeling, and color/material customization

Cross-reference service claims with verified performance metrics such as on-time delivery rates (target ≥98%) and reorder rates (indicative of customer satisfaction).

Quality and Compliance Standards

While explicit certification data is not provided, prioritize suppliers demonstrating adherence to international quality benchmarks. Request evidence of ISO 9001 implementation, RoHS compliance, and traceability systems for component lot tracking. For consumer-facing electronics, verify EMC and safety testing capabilities aligned with destination-market regulations (e.g., FCC, CE).

Transaction and Risk Mitigation

Utilize incremental engagement strategies: start with sample orders to evaluate build quality and communication responsiveness. Require detailed documentation—including BOMs, test reports, and assembly drawings—before scaling production. Confirm packaging and labeling customization options to meet branding or regulatory requirements. Analyze online revenue indicators and response time consistency as proxies for operational stability.

What Are the Best Custom Made Electronics Suppliers?

| Company Name | Verified Type | Main Products/Services | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| ShenZhen Nova Semiconductor Co., Ltd | Brand Holder | PCBA, Electronic Musical Instruments, Kids' Electronic Toys | 3D preview, Gerber file, design, PCBA assembly, PCB | 98% | ≤3h | 33% | US $110,000+ | 1–10 pieces |

| Suzhou Engine Electronic Technology Co., Ltd. | Multispecialty Supplier | OEM/ODM PCBA, SMT Components, Electronic Manufacturing Services | PCB design, color, size, logo, packaging, label, engineering | 100% | ≤3h | <15% | US $50,000+ | 1 piece |

| Shenzhen Kelvin Electronics Co., Ltd. | Not Specified | Remote Controls, Wireless Switches, Consumer Electronics | Color, material, size, logo, packaging | 96% | ≤2h | <15% | US $160,000+ | 1 piece |

| FENG CHENG MACHINERY INDUSTRIAL CO., LTD. | Not Specified | CNC Machining, Forging, Casting, Pneumatic Nailers | Limited electronics-specific customization | 100% | ≤3h | 16% | US $1,000+ | 100–500 pieces |

| Shenzhen Times Precision Manufacturing Co., Ltd. | Custom Manufacturer | Machining Services, Precision Components | Color, material, size, logo, packaging, graphic | 100% | ≤6h | Not Available | US $80,000+ | Not Publicly Listed |

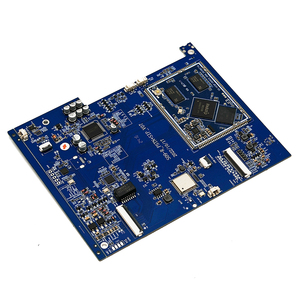

Performance Analysis

ShenZhen Nova Semiconductor stands out for end-to-end electronics customization with strong reorder activity (33%) and low MOQs, indicating high client retention in niche segments like musical instruments and educational toys. Suzhou Engine Electronic Technology offers complete OEM/ODM services with full design flexibility and perfect on-time delivery, though lower reorder rates suggest room for improvement in long-term client engagement. Shenzhen Kelvin Electronics specializes in wireless control systems with scalable pricing and single-piece ordering, suitable for startups and IoT developers.

FENG CHENG MACHINERY and Shenzhen Times Precision focus primarily on mechanical components, with limited electronics integration—making them better suited for hybrid electromechanical builds rather than pure electronic devices. Suppliers with sub-3-hour response times and MOQs of 1 piece provide maximum agility for prototyping and small-batch innovation. For high-reliability applications, prioritize partners with documented PCBA processes and multi-layer quality checks.

FAQs

How to verify custom electronics supplier capability?

Request facility videos showcasing SMT lines, reflow ovens, and testing stations. Evaluate technical responsiveness by submitting a sample design package (Gerber + BOM) and measuring feedback accuracy and turnaround time. Confirm packaging and branding customization options prior to order placement.

What is the typical lead time for custom electronic assemblies?

Prototype lead times range from 7–14 days for simple PCBAs. Complex designs requiring component sourcing or iterative revisions may take 3–5 weeks. Mass production (1,000+ units) typically follows in 20–30 days after sample approval.

Can suppliers handle full product development from concept to delivery?

Yes, select suppliers offer turnkey solutions including circuit design, firmware development, enclosure integration, and compliance testing. Companies like Suzhou Engine Electronic Technology and ShenZhen Nova Semiconductor explicitly support design-to-production workflows with engineering collaboration.

Do custom electronics suppliers offer free samples?

Sample policies vary. Some suppliers absorb costs for qualified buyers committing to volume production. Others charge nominal fees covering materials and labor, typically refundable against future orders exceeding 500 units.

What are common customization options for electronic products?

Available options include PCB layout modifications, component selection, firmware personalization, color finishes, branding (logo/label), packaging formats, and mechanical housing integration. Advanced providers support 3D rendering and functional prototypes for pre-production validation.