Custom Fabric Maker

About custom fabric maker

Where to Find Custom Fabric Maker Suppliers?

China remains the global epicenter for custom fabric manufacturing, with key production hubs in Zhejiang, Guangdong, and Jiangsu provinces offering integrated textile ecosystems. Shaoxing in Zhejiang dominates woven and printed fabric output, hosting over 70% of China’s digital printing capacity for textiles. Guangzhou in Guangdong specializes in high-end fashion fabrics, including lace, mesh, and embroidered materials, supported by agile small-batch production networks. Suzhou and surrounding areas in Jiangsu focus on technical and functional textiles, leveraging automated looms and dyeing systems for consistent quality at scale.

These clusters enable vertical integration from fiber extrusion to finishing and printing, reducing lead times by up to 40% compared to decentralized supply chains. Manufacturers operate with in-house design studios, digital printing units, and dye labs, allowing full-cycle customization—from concept to bulk production—within 15–25 days for standard orders. Buyers benefit from localized access to raw materials (polyester, cotton, spandex), advanced processing techniques (digital sublimation, screen printing, embossing), and flexible MOQs ranging from 1 meter to multi-kilometer runs.

How to Choose Custom Fabric Maker Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure quality consistency, compliance, and operational reliability:

Production & Technical Capabilities

Confirm suppliers operate their own production lines with control over knitting, weaving, dyeing, and printing processes. Prioritize facilities equipped with digital printing systems (e.g., Kornit, MS Printech) for accurate color reproduction and complex pattern replication. Verify minimum monthly output capacity—ideally exceeding 50,000 meters—for scalability. In-house R&D teams support rapid prototyping and material innovation, particularly for performance fabrics requiring moisture-wicking, UV resistance, or flame retardancy.

Customization Scope and Flexibility

Assess the breadth of customization options offered:

- Fabric composition (cotton, polyester, spandex, silk, blends)

- Weave/knit type (poplin, chiffon, jersey, double-brushed poly, minky)

- Digital or screen printing with Pantone-matched colors

- Labeling, packaging, and branding (woven labels, confidential packaging, custom tags)

- Design input formats (AI, PSD, high-res JPEG) and turnaround time for proofs

Suppliers should accommodate both small test batches (as low as 1 yard or 1 meter) and large-volume contracts (1,000+ meters), ensuring adaptability across product development stages.

Quality Assurance and Compliance

While formal certifications (ISO 9001, OEKO-TEX, REACH) are not universally declared in available data, buyers must request documentation verifying material safety, colorfastness, and environmental standards. Conduct pre-shipment inspections to validate fabric weight (gsm), width tolerance, shrinkage rates, and print alignment. Evaluate response time (target ≤6 hours) and on-time delivery performance (benchmark ≥98%) as indirect indicators of operational discipline.

Transaction Security and Sampling

Utilize secure payment methods with escrow functionality to mitigate risk during initial engagements. Request physical or digital samples before committing to bulk orders—many suppliers offer sample cuts at minimal cost or included in early production runs. Analyze reorder rates (ranging from 15% to 31% among reviewed suppliers) as a proxy for customer satisfaction and product reliability.

What Are the Best Custom Fabric Maker Suppliers?

| Company Name | Main Materials | Customization Options | MOQ Range | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Shaoxing Fulaida Import & Export Co., Ltd. | Cotton, polyester, spandex, minky | Design, print, color, size, label, logo, graphic | 1 yard | 100% | ≤7h | US $290,000+ | 31% |

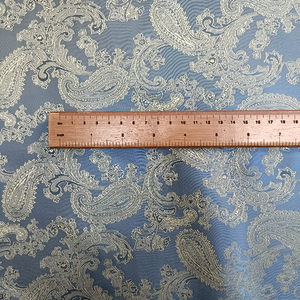

| Guangzhou Supoo Trading Co., Ltd. | Silk, satin, brocade, lace, beads, stones | Embroidery, applique, print, color, bundle styles | 5–100 yards | 98% | ≤6h | US $310,000+ | 25% |

| Suzhou Yibi Textile Co., Ltd. | Polyester, jacquard, plaid, satin | Print, color, size, label, logo, graphic | 1–50 meters | 98% | ≤2h | US $70,000+ | 15% |

| Guangzhou Tianwang Heye Textile Co., Ltd. | Cotton, polyester, knit | Digital print, watermark, color, pattern, logo | 50–1000 meters | 98% | ≤2h | US $30,000+ | 21% |

| Jiaxing Xinhaosheng Trade Co., Ltd. | 100% polyester, velvet, upholstery | Embossed, printed, color, design, packaging | 10–3000 meters | Not specified | ≤11h | US $100+ | <15% |

Performance Analysis

Shaoxing Fulaida stands out with a 100% on-time delivery rate and the highest reorder rate (31%), indicating strong customer retention and process reliability. Guangzhou Supoo leads in revenue volume (US $310,000+) and offers extensive embellishment capabilities ideal for luxury fashion applications. Suzhou Yibi and Guangzhou Tianwang Heye demonstrate superior responsiveness (≤2h average), critical for fast-turnaround design iterations. Jiaxing Xinhaosheng serves niche markets with high-volume upholstery solutions but shows lower transactional activity and delayed response metrics. Buyers seeking low MOQs should prioritize Shaoxing Fulaida or Suzhou Yibi, while those requiring mass production may leverage Guangzhou-based suppliers for scalable digital printing capacity.

FAQs

How to verify a custom fabric maker’s production capability?

Request facility videos or virtual tours showing printing machines, dye vats, and inspection stations. Confirm ownership of production equipment versus trading-only operations. Review order history for evidence of large-scale fulfillment (e.g., 1,000+ meter runs) and cross-check claimed capabilities with delivered product specifications.

What is the typical lead time for customized fabric orders?

Sample production takes 7–14 days depending on complexity. Bulk orders (500–3,000 meters) typically require 15–25 days, including design approval, batching, printing, and quality checks. Expedited services may reduce timelines by 30% for urgent needs.

Can suppliers match specific color standards?

Yes, most digital printing facilities support Pantone matching and RGB/CMYK conversion. Provide high-resolution artwork with defined color profiles. Some suppliers offer pre-print proofs via email or physical swatches for validation prior to full production.

Are small MOQs available for startups or designers?

Several suppliers offer MOQs as low as 1 yard or 1 meter, particularly for digital printing services. Shaoxing Fulaida and Suzhou Yibi cater effectively to small businesses and independent designers needing prototype validation before scaling.

How are custom designs protected during production?

Reputable suppliers implement confidentiality measures such as encrypted file transfers, restricted access to design databases, and neutral packaging without branding. For added protection, execute NDAs and limit distribution of final artwork to essential personnel only.