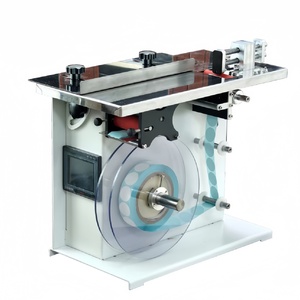

Custom Label Machine

1/10

1/10

1/15

1/15

1/12

1/12

1/20

1/20

1/5

1/5

1/8

1/8

1/12

1/12

1/13

1/13

1/25

1/25

1/31

1/31

CN

CN

About custom label machine

Where to Find Custom Label Machine Suppliers?

China remains the global epicenter for custom label machine manufacturing, with key industrial hubs in Guangdong, Shanghai, and Shandong provinces driving innovation and scale. Dongguan and Guangzhou in Guangdong province host advanced automation clusters specializing in compact desktop and semi-automatic labeling systems, ideal for small-to-medium enterprises requiring flexible production setups. Shanghai’s machinery corridor supports high-end OEM manufacturers equipped with precision engineering capabilities for fully automatic, high-speed labeling lines serving pharmaceutical, beverage, and cosmetics industries.

These regions benefit from vertically integrated supply chains—spanning servo motors, sensor arrays, and control systems—enabling rapid prototyping and reduced component lead times. Suppliers leverage localized access to CNC machining, sheet metal fabrication, and electronics assembly, achieving 20–35% lower unit costs compared to Western counterparts. Buyers gain access to agile production ecosystems capable of fulfilling orders within 15–30 days for standard configurations, with customization lead times averaging 25–40 days depending on technical complexity.

How to Choose Custom Label Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Prioritize suppliers offering CE certification as a baseline for electrical safety and regulatory compliance in international markets. For food, pharmaceutical, or cosmetic applications, verify adherence to hygienic design standards and stainless steel construction where applicable. Request test reports for critical subsystems such as labeling accuracy (±0.5mm tolerance), sensor responsiveness, and motor longevity under continuous operation.

Production Capability Assessment

Evaluate core infrastructure indicators:

- Minimum factory area exceeding 3,000m² to support dedicated assembly and testing zones

- In-house engineering teams enabling mechanical and software-level customization

- Integration of PLC-based control systems and compatibility with Industry 4.0 protocols

Cross-reference declared capabilities with online revenue data and on-time delivery rates—target suppliers maintaining ≥96% fulfillment punctuality.

Customization & Quality Assurance

Confirm scope of customization: supported label formats (self-adhesive, shrink sleeve, wrap-around), material compatibility (PET, PVC, paper), and integration options (conveyor linkage, multi-head dispensing). Validate quality control procedures including pre-shipment run tests, calibration documentation, and traceability logs. Favor suppliers offering video audits or real-time production monitoring for remote verification.

What Are the Best Custom Label Machine Suppliers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Scope |

|---|---|---|---|---|---|---|---|

| Dongguan BanMo Machinery Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $390,000+ | 99% | ≤2h | <15% | Color, size, logo, packaging, graphic, material |

| Shanghai Suhe Enterprises Co., Ltd. | Shanghai, CN | Multispecialty Supplier | US $540,000+ | 100% | ≤2h | 33% | Color, size, logo, label, graphic, capacity |

| Shanghai Skilt Machinery Equipment Co., Ltd. | Shanghai, CN | Custom Manufacturer | US $1,300,000+ | 92% | ≤2h | 25% | Bottle diameter, label height, speed, sensor type, material, logo, non-stop function |

| Shanghai Poshysmart Intelligent Equipment Co., Ltd. | Shanghai, CN | Custom Manufacturer | US $280,000+ | 96% | ≤3h | 35% | Color, material, size, logo, packaging, graphic |

| Shandong Yizhou Science And Technology Development Co., Ltd. | Shandong, CN | - | US $130,000+ | 97% | ≤2h | 33% | Limited customization; broader packaging equipment portfolio |

Performance Analysis

Shanghai-based suppliers dominate in customization depth and export readiness, with Shanghai Suhe Enterprises achieving perfect on-time delivery and robust reorder metrics. Dongguan BanMo stands out for entry-level automation with low MOQs (1 piece) and responsive service, suitable for startups and pilot runs. Shanghai Skilt offers the most technically granular customization—supporting parameters like transparent bottle detection and non-stop labeling—ideal for complex production environments. High reorder rates (≥33%) among mid-tier suppliers indicate consistent performance and post-sale support. For mission-critical deployments, prioritize manufacturers with documented R&D investment and modular design platforms enabling future scalability.

FAQs

What is the typical MOQ for custom label machines?

Most suppliers offer a minimum order quantity of 1 set, particularly for semi-automatic and desktop models. Fully automatic lines may require 1–2 sets for initial orders. Bulk pricing typically applies at 5+ units, with incremental cost reductions up to 20% at 10+ units.

How long does customization take?

Standard modifications (logo integration, color scheme, basic dimensional adjustments) add 5–10 days to lead time. Full mechanical reconfiguration or software adaptation for specialized containers (e.g., irregular shapes, tapered bottles) extends timelines to 30–45 days. Prototypes are generally available within 3 weeks upon final specification approval.

Do suppliers provide technical documentation and after-sales support?

Reputable manufacturers supply operation manuals, wiring diagrams, and PLC programming guides. Remote troubleshooting via video call or TeamViewer is commonly offered. Some providers include installation assistance or on-site training for large-scale systems, especially under CIF shipping terms.

Can these machines handle different label types?

Yes, many models support interchangeable rollers and sensor settings for self-adhesive labels, shrink sleeves, and wraparound stickers. High-end systems feature quick-change tooling to switch between round, flat, and oval container labeling within 15 minutes, minimizing downtime during batch transitions.

What payment and logistics options are available?

Common payment terms include T/T (30% deposit, 70% before shipment) or platform-backed escrow services. FOB terms are standard; CIF arrangements are negotiable for full-container loads. Air freight enables delivery in 5–7 days for urgent samples, while sea freight takes 20–35 days depending on destination port congestion.