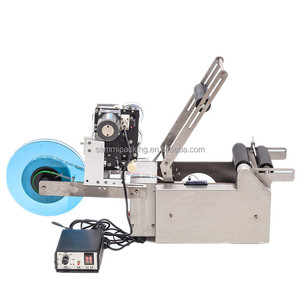

Label Making Machine

CN

CN

About label making machine

Where to Find Label Making Machine Suppliers?

China remains the central hub for label making machine manufacturing, with key industrial clusters in Zhejiang, Anhui, and Guangdong provinces driving innovation and cost efficiency. Wenzhou in Zhejiang specializes in intelligent labeling equipment, hosting firms with advanced R&D capabilities in automation and sensor integration. Hefei (Anhui) and Guangzhou (Guangdong) focus on mid-to-high-end semi-automatic and fully automatic systems, leveraging regional supply chains for motors, PLCs, and pneumatic components.

These hubs benefit from vertically integrated production ecosystems, where component sourcing, machining, and final assembly occur within compact geographic zones. This structure reduces lead times to 20–35 days for standard units and supports flexible MOQs as low as 1 set. Localized access to sheet metal fabrication, CNC processing, and electronic control systems enables 15–25% lower production costs compared to equivalent machinery sourced from Europe or North America.

How to Choose Label Making Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and transactional security:

Technical Compliance & Certification

Verify adherence to international quality standards such as ISO 9001 for quality management. For exports to regulated markets, confirm CE marking compliance to meet EU safety, health, and environmental requirements. Request documentation on electrical system certifications (e.g., CB Scheme) and material RoHS compliance, particularly for machines used in food, pharmaceutical, or cosmetic labeling applications.

Production Capability Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Facility size exceeding 2,000m² indicates capacity for batch production

- In-house engineering teams capable of customizing labeling speed, sensor types (optical/magnetic), and integration with conveyor systems

- On-site testing protocols for accuracy (±0.5mm tolerance), cycle durability (10,000+ cycles), and compatibility with adhesive, wraparound, or pressure-sensitive labels

Cross-reference performance claims with on-time delivery rates above 98% and response times under 4 hours to assess operational responsiveness.

Transaction Security & Quality Assurance

Prioritize suppliers offering third-party inspection options prior to shipment. Utilize secure payment mechanisms that release funds upon verification of machine functionality at destination. Conduct sample testing to validate labeling precision across substrate types (plastic, glass, cardboard) and environmental conditions (humidity, temperature). Confirm post-delivery support availability for troubleshooting and spare parts supply.

What Are the Best Label Making Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Lanhai Finenorm Coding Co., Ltd. | Shanghai, CN | Coding Machines (347), Labeling Machines (25) | US $80,000+ | 100% | ≤2h | 21% | No data | 1 acre |

| Hefei Better Technology Co., Ltd. | Anhui, CN | Cable Manufacturing Equipment (1408), Paper Processing Machinery (115) | US $40,000+ | 100% | ≤4h | <15% | No data | 1 set |

| Wenzhou Aimesk Intelligent Equipment Co., Ltd. | Zhejiang, CN | Labeling Machines, Custom Automation Solutions | US $320,000+ | 99% | ≤2h | <15% | Color, size, logo, packaging, graphic | 1 set |

| Taizhou Fansi Machinery Manufacturing Co., Ltd. | Zhejiang, CN | Stretch Blow Moulding Machines (23), Labeling Machines (21) | Data not available | 100% | ≤5h | No data | No data | 1 piece |

| Guangzhou Tengzhuo Packing Equipment Co., Ltd. | Guangdong, CN | Automatic & Semi-Automatic Labeling Systems | US $60,000+ | 100% | ≤1h | 33% | No data | 1 set |

Performance Analysis

Wenzhou Aimesk leads in customization flexibility and digital sales volume (US $320,000+ online revenue), indicating strong market penetration and adaptability to diverse client specifications. Guangzhou Tengzhuo stands out with a 33% reorder rate and sub-hour response time, reflecting high customer satisfaction and operational agility. Lanhai Finenorm and Hefei Better Technology demonstrate consistent on-time delivery (100%) but offer limited customization visibility. Taizhou Fansi, while lacking public revenue metrics, lists high-end automatic models priced up to $8,888, suggesting specialization in premium equipment. Buyers seeking rapid prototyping and tailored integration should prioritize suppliers with documented customization options and responsive communication channels.

FAQs

How to verify label making machine supplier reliability?

Validate certifications through official registries and request factory audit reports or video walkthroughs. Analyze transaction history indicators such as on-time delivery rate, response time, and reorder frequency. Review product listings for consistency in technical detail and supported languages, which reflect professional export readiness.

What is the typical lead time for label making machines?

Standard models are typically delivered within 20–30 days after order confirmation. Custom-built systems may require 35–50 days depending on complexity. Express production surcharges can reduce timelines by 7–10 days for urgent procurement needs.

Do suppliers support OEM/ODM labeling solutions?

Yes, select manufacturers offer OEM branding and ODM design services. Wenzhou Aimesk explicitly lists logo, color, and packaging customization. Confirm minimum branding quantities and artwork specification requirements before engagement.

What are common MOQs for label applicators?

Most suppliers accept MOQs of 1 set or 1 piece, especially for automated benchtop models. Bulk pricing applies from 5 units onward, with discounts ranging from 5–15% based on volume and negotiation terms.

Can label machines handle different container shapes?

Yes, modern systems support flat, round, oval, and irregular surfaces. Key differentiators include adjustable rollers, programmable PLC controls, and interchangeable tamp pads or brush assemblies. Confirm compatibility with bottle diameter, height, and label size range during technical review.