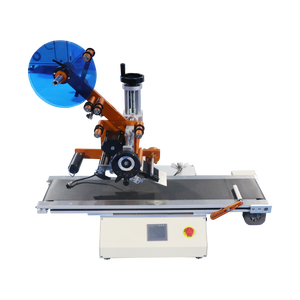

Label Making Machine For Clothes

About label making machine for clothes

Where to Find Label Making Machine Suppliers for Clothes?

China remains the global epicenter for textile labeling equipment manufacturing, with key supplier clusters concentrated in Guangdong and Dongguan. These regions host vertically integrated industrial ecosystems that specialize in both standalone label application systems and full-scale woven label production lines. Guangzhou-based manufacturers focus on compact, entry-level hot-stamping and foil-printing machines suited for small apparel brands and private labeling operations. In contrast, Dongguan’s industrial base caters to high-volume textile producers, offering automated weaving, cutting, and folding machinery capable of processing polyester, satin, cotton, and synthetic ribbons at scale.

The proximity of raw material suppliers, component fabricators, and logistics networks enables rapid prototyping and efficient order fulfillment. Buyers benefit from localized supply chains that reduce lead times by 20–30% compared to offshore alternatives. Standard delivery windows range from 15 to 30 days for stock models, while customized machinery may require 45–60 days depending on technical complexity. Regional advantages include access to precision die-cutting tools, embossing dies, and digital control systems—all produced within a 100km radius, minimizing procurement delays and transportation costs.

How to Choose Label Making Machine Suppliers for Clothes?

Selecting reliable suppliers requires systematic evaluation across three core dimensions:

Technical Capability & Production Infrastructure

Assess whether suppliers operate dedicated production lines for label-making systems. Prioritize manufacturers with documented experience in thermal transfer, heat pressing, laser holography, or automatic ribbon feeding mechanisms. For woven labels, verify integration of jacquard looms and high-speed cutting units. Facilities should maintain minimum floor areas exceeding 2,000m² to ensure scalability, supported by in-house engineering teams responsible for machine calibration and after-sales support.

Quality Assurance and Compliance

Confirm adherence to international quality benchmarks such as ISO 9001. While not all suppliers hold CE certification, those targeting export markets typically comply with electrical safety standards for motorized components. Request test reports for temperature stability (critical for hot-foil stamping), pressure consistency (for embossing clarity), and mechanical durability under continuous operation. Suppliers with online revenues exceeding $300,000 annually demonstrate sustained market validation and process maturity.

Customization and Transaction Reliability

Evaluate customization depth—leading suppliers offer variable options including label size, fabric width, logo embossing, color palettes, roll length, and packaging configurations. Cross-reference response times (target ≤3 hours) and on-time delivery rates (ideally ≥95%) as indicators of operational efficiency. Reorder rates above 40% suggest strong customer satisfaction, particularly when paired with responsive communication channels and transparent order tracking.

What Are the Best Label Making Machine Suppliers for Clothes?

| Company Name | Location | Main Products | Production Focus | Min. Order Quantity | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Weilong Machinery Co., Ltd. | Guangzhou, CN | Heat Press Machines (622 listings) | Digital hot-foil stamping, manual embossing, heat transfer systems | 1 piece | $84.24–739 | 97% | ≤2h | 15% |

| Dongguan Plus Industry Investment Co., Ltd. | Dongguan, CN | Weaving Machines (49 listings) | Woven label looms, Muller-type cutters, high-speed garment tag systems | 1 set | $6,600–50,000 | 100% | ≤5h | 100% |

| Guangzhou Lixin Printing & Packaging Co., Ltd. | Guangzhou, CN | Custom woven labels (customization-focused) | Pre-made clothing labels (satin, PVC, cotton canvas) | 100 pieces | $0.03/unit | 96% | ≤3h | 22% |

| Qingdao Pingte Machinery Equipmake Co., Ltd. | Qingdao, CN | Screen Printers (384), Heat Transfer Machines (341) | Automatic care label applicators, flexo printing, DTF integration | 1 set | $5,000–29,000 | 95% | ≤6h | 40% |

| Hebei Hanze International Trade Co., Ltd. | Hebei, CN | Label tag guns, handheld applicators | DIY garment tagging tools, hanging label systems | 2–100 pieces | $1.80–130 | 100% | ≤3h | <15% |

Performance Analysis

Dongguan Plus Industry stands out for industrial-grade solutions, offering complete used and new weaving systems with a 100% reorder rate, indicating high client retention among large textile producers. Qingdao Pingte demonstrates strong after-sales performance with a 40% reorder rate despite a slower response time, suggesting reliability in execution. Guangzhou Weilong provides cost-effective entry-level machines ideal for startups, backed by fast response times (≤2h) and diversified product offerings. Hebei Hanze specializes in low-cost manual tools suitable for small-batch garment finishing, though lower reorder metrics suggest less repeat engagement. Guangzhou Lixin diverges from machinery supply by focusing on pre-produced custom labels rather than machines, serving clients seeking ready-to-use branding elements without capital investment in equipment.

FAQs

How to verify label making machine supplier reliability?

Cross-check claimed certifications with third-party verification platforms. Analyze transaction histories, focusing on consistent on-time delivery records (>95%) and verifiable customer reviews. Request facility videos or virtual audits to confirm production capabilities, especially for high-value automated systems.

What is the typical MOQ and pricing structure?

Entry-level stamping and heat press machines are available from $84 with MOQs of 1 unit. Full automated systems start at $5,000 per set. For label rolls or tags, MOQs begin at 100 pieces with unit prices as low as $0.03. Handheld applicators are offered in batches of 2–100 units.

Can suppliers accommodate custom label designs and sizes?

Yes, most suppliers support customization of label dimensions, materials (polyester, satin, cotton, PVC), logos, colors, and packaging formats. Advanced options include 3D holographic effects, transparent overlays, and folded/woven configurations. Technical specifications must be submitted in vector format for die creation and sample production.

What are standard lead times for samples and bulk orders?

Sample production typically takes 7–15 days, depending on complexity. Bulk order fulfillment ranges from 15–30 days for standard machines and 45–60 days for fully customized systems. Air freight delivers samples in 5–10 days internationally; sea freight is recommended for full container loads to minimize shipping costs.

Do manufacturers provide technical support and spare parts?

Reputable suppliers offer post-delivery support including machine setup guidance, operational training, and availability of critical spares such as heating elements, pressure rollers, and cutting blades. Long-term service agreements may be negotiated for continuous maintenance, particularly for high-utilization environments.