Custom Made Machine

Top sponsor listing

Top sponsor listing

CN

CN

About custom made machine

Where to Find Custom Made Machine Suppliers?

China remains the global epicenter for custom made machine manufacturing, with key production hubs concentrated in Guangdong, Fujian, and Shanxi provinces. These regions host vertically integrated industrial ecosystems combining precision machining, sheet metal fabrication, casting, and CNC processing under one supply chain. Shenzhen (Guangdong) excels in high-precision 5-axis milling and rapid prototyping, supporting tight-tolerance components for automation and semiconductor equipment. Xiamen (Fujian) specializes in large-scale OEM machinery foundations and heavy cast structures, leveraging proximity to steel suppliers for cost-efficient tonnage-based production. Taiyuan (Shanxi) focuses on forged and wear-resistant mechanical parts, catering to mining, energy, and agricultural machinery sectors.

The clustering enables suppliers to offer end-to-end engineering services—from concept drawings to finished assemblies—with localized component sourcing reducing lead times by 20–30% compared to offshore alternatives. Buyers benefit from scalable production models capable of fulfilling low-volume prototypes (1-piece MOQ) or mass production runs exceeding 50,000 units. Average lead times range from 15–35 days depending on complexity, with express prototyping available within 7–10 days for validated designs.

How to Choose Custom Made Machine Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

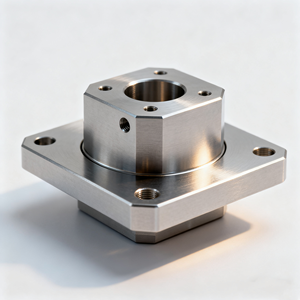

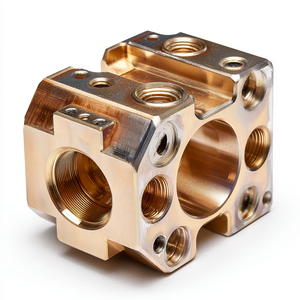

Engineering & Manufacturing Capabilities

Assess whether the supplier maintains in-house design and fabrication infrastructure. Key indicators include multi-axis CNC machining (4-axis and 5-axis), anodizing/sandblasting surface treatments, welding, laser cutting, and casting capabilities. Prioritize suppliers offering full documentation support—dimensional drawings, material certifications, and GD&T specifications. For complex assemblies, confirm integration of sheet metal, machining, and assembly lines within a single facility to minimize coordination delays.

Quality Assurance Protocols

While formal ISO 9001 certification is not uniformly listed in available data, consistent on-time delivery rates (≥97%) and documented response times (≤3 hours) serve as proxies for operational discipline. Suppliers advertising 100% on-time delivery across multiple records demonstrate process reliability. Inquire directly about internal quality control checkpoints, first-article inspection (FAI) procedures, and use of coordinate measuring machines (CMM) for dimensional validation.

Customization Scope and Flexibility

Evaluate customization depth beyond basic material or size adjustments. Leading providers support:

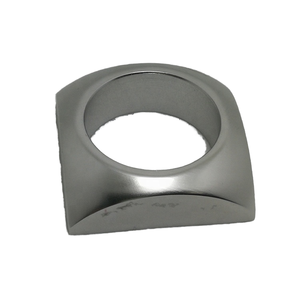

- Material selection: aluminum, stainless steel, carbon steel, brass, titanium, and engineered plastics

- Finishing options: anodized, sandblasted, polished, powder-coated, electroplated

- Branding integration: laser engraving, logo embossing, label application

- Design iteration: DFM feedback, 3D modeling, prototype validation

Confirm that technical teams can interpret CAD files (STEP, IGES, DWG) and provide design-for-manufacturability suggestions prior to tooling.

Transaction Risk Mitigation

Utilize secure payment terms such as escrow or milestone-based disbursements tied to production stages. Request sample units before committing to bulk orders—especially for first-time engagements. Analyze reorder rates where available; suppliers with >25% repeat business indicate customer satisfaction and service consistency. Response time ≤1 hour correlates with higher engagement and post-sale support responsiveness.

What Are the Best Custom Made Machine Suppliers?

| Company Name | Location | Main Services | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| ShenZhen Selection Hardware Technology Co.,Ltd. | Shenzhen, CN | Machining, Casting, Sheet Metal Fabrication | Color, material, size, finish, logo, packaging, 5-axis machining | 100% | ≤1h | US $1,900,000+ | 25% | 1 piece / 1 ton |

| JUNYING METAL MANUFACTURING CO., LIMITED | Dongguan, CN | Precision CNC Machining | Limited customization per product line | 100% | ≤6h | Not disclosed | Unavailable | 1–100 pieces |

| Xiamen Openex Mechanical Technology Limited | Xiamen, CN | OEM Machining, Casting, Sheet Metal, Sorting Machines | Frame, base, chassis customization; heat treatment | 100% | ≤3h | Not disclosed | Unavailable | 1 ton minimum |

| Taiyuan Realand Machinery Equipment Co., Ltd. | Taiyuan, CN | CNC Machining, Forging, Wear-Resistant Parts | Color, material, size, logo, packaging, graphics | 75% | ≤4h | US $9,000+ | <15% | 1 piece / 1 kg / 500 pcs |

| Shenzhen Rmt Precision Tech Co., Ltd. | Shenzhen, CN | CNC Milling, Machining, Sheet Metal | Aluminum/stainless steel accessories, OEM/ODM | 100% | ≤4h | Not disclosed | Unavailable | 1 piece |

Performance Analysis

ShenZhen Selection Hardware stands out with the highest online revenue (US $1.9M+), sub-hour response time, and verified 25% reorder rate, indicating strong market acceptance and customer retention. Its comprehensive service portfolio supports diverse customization needs across materials, finishes, and geometries. Shenzhen Rmt Precision Tech and JUNYING METAL both report 100% on-time delivery, signaling robust production planning, though JUNYING’s longer response time suggests potential bottlenecks in communication. Xiamen Openex targets heavy industrial applications with tonnage-based pricing, ideal for large structural components but less suited for small-batch prototyping. Taiyuan Realand, while offering flexible order sizes, exhibits lower delivery performance (75%) and minimal repeat business, suggesting room for improvement in consistency.

FAQs

How to verify custom made machine supplier reliability?

Request evidence of production capacity through factory videos, equipment lists, and staff headcount. Cross-reference delivery performance with third-party transaction platforms. Conduct virtual audits to observe workflow segmentation between design, machining, quality control, and shipping departments.

What is the typical MOQ for custom machine components?

MOQ varies by supplier and material form. Machined parts often start at 1 piece, especially in Shenzhen-based facilities. Cast or forged components may require minimum tonnage (e.g., 1 ton) due to furnace batch constraints. Sheet metal fabricators typically accept runs from 50–500 units depending on complexity.

What are common lead times for customized machines or parts?

Standard lead time ranges from 15–35 days post-design approval. Rapid prototyping services can deliver functional samples within 7–14 days. Complex integrations involving casting, heat treatment, and surface finishing may extend timelines to 45 days.

Do suppliers support international shipping and customs clearance?

Yes, most established manufacturers export globally and offer FOB, CIF, or DDP shipping terms. Confirm that suppliers can generate commercial invoices, packing lists, and material test certificates (MTC) required for customs entry. Some provide freight forwarding coordination for containerized shipments.

How to initiate a customization request effectively?

Submit detailed technical packages including 2D/3D drawings, bill of materials (BOM), tolerances, surface finish requirements, and intended application. Clearly specify regulatory standards (e.g., RoHS, REACH) if applicable. Reputable suppliers will respond with DFM feedback, timeline estimates, and prototype quotes within 24–72 hours.