Custom Material Forging

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

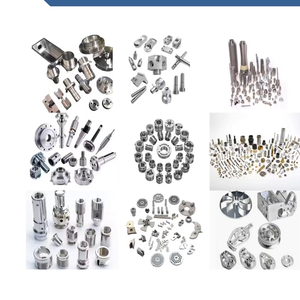

About custom material forging

Where to Find Custom Material Forging Suppliers?

China remains the global epicenter for custom material forging services, with key industrial hubs in Shandong, Henan, and Guangdong provinces driving production efficiency and technical specialization. Shandong’s Qingdao region hosts advanced metalworking clusters integrating forging, machining, and casting under one ecosystem, enabling end-to-end component manufacturing within tightly controlled supply chains. Henan province has emerged as a center for high-volume steel forging, supported by regional access to raw materials and energy infrastructure that reduce input costs by 15–25% compared to international benchmarks.

These manufacturing zones benefit from vertically integrated operations—spanning die design, heat treatment, CNC finishing, and quality inspection—allowing lead times as short as 20–35 days for customized orders. Suppliers in these regions typically operate multi-process facilities within 50km of upstream steel producers and downstream assembly clients, minimizing logistics delays. Buyers gain access to scalable production capacities, with many suppliers capable of monthly outputs exceeding 500 tons of forged components across carbon steel, alloy steel, aluminum, brass, and specialty alloys like 40CrNiMo, 42CrMo, and GH4169.

How to Choose Custom Material Forging Suppliers?

Effective supplier selection requires systematic evaluation across three core dimensions:

Technical & Process Capabilities

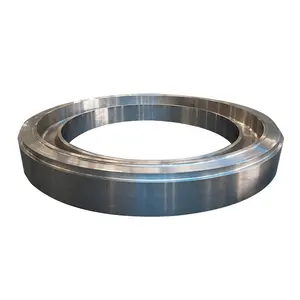

Verify that suppliers possess in-house capabilities for hot/cold forging, precision die forging, and post-forging processes such as CNC machining, surface treatments, and non-destructive testing. Preferred partners maintain dedicated R&D or engineering teams to support design validation and prototype development. Confirm compatibility with required materials—including low-alloy steels, stainless grades, and non-ferrous metals—and assess tooling infrastructure for complex geometries.

Quality Assurance Systems

While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates (≥100%) and documented response times ≤4 hours indicate operational discipline. Prioritize suppliers offering dimensional inspection reports, material traceability documentation, and process control plans. For regulated industries (e.g., aerospace, automotive), request evidence of compliance with ASTM, DIN, or JIS standards and internal QA protocols such as first-article inspection and batch testing.

Transaction Reliability Indicators

Analyze performance metrics where available: 100% on-time delivery is common among top-tier providers, while reorder rates vary significantly—from below 15% to full customer retention—indicating differences in service consistency. Fast response times (≤1 hour) correlate with higher engagement levels. Minimum order quantities (MOQs) range from 1 piece for prototyping to 1,000+ pieces for mass production, allowing flexibility based on project phase. Escrow-based payment terms and sample validation are recommended before scaling procurement.

What Are the Best Custom Material Forging Suppliers?

| Company Name | Location | Main Materials | Processing Methods | On-Time Delivery | Avg. Response | MOQ Range | Price Range (USD) | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Jiyuan Haiyuan Special Steel Co., Ltd. | Henan, CN | 40CrNiMo, 42CrMo, GH4169, Alloy Steel | Precision Forging, CNC Machining, Heat Treatment | 100.0% | ≤1h | 1–5 pcs | $25–680 | - |

| Qingdao Sande Tech Co., Ltd. | Shandong, CN | Steel, Aluminum, Copper, Brass | Diesel Forging, CNC Finishing, Casting Integration | 100.0% | ≤1h | 1–10 pcs | $0.50–2.00 | - |

| Foshan Xinxiang Metal Materials Co., Ltd. | Guangdong, CN | Aluminum Alloys, Carbon Steel | Precision CNC, Anodizing, Forging Support | 100.0% | ≤1h | 1,000 pcs | $7–9 | - |

| Henan Forging Emperor Industry Co., Ltd. | Henan, CN | Carbon Steel, Alloy Steel | Hot Forging, Machining, Sheet Metal Fabrication | 100.0% | ≤3h | 1,000–2,000 pcs | $4–20 | <15% |

| Zhongshan Meichen Hardware Products Factory | Guangdong, CN | Custom Ferrous & Non-Ferrous Alloys | Machining, Casting, Motorcycle Component Forging | 100.0% | ≤4h | Not specified | Not specified | 100% |

Performance Analysis

Jiyuan Haiyuan Special Steel stands out for high-value alloy forging applications, particularly in aerospace-grade materials like GH4169, with pricing reflecting technical complexity. Qingdao Sande Tech offers the lowest per-unit cost structure ($0.50–$2.00), ideal for small-batch prototyping across diverse metals. Foshan Xinxiang specializes in aluminum forgings paired with anodizing, targeting lightweight industrial and consumer applications at scale (MOQ 1,000 pcs). Henan Forging Emperor provides competitive pricing for standardized steel forgings but exhibits lower repeat business (<15% reorder rate), suggesting potential gaps in customization or communication. Zhongshan Meichen demonstrates perfect reorder performance (100%), indicating strong client satisfaction despite limited public transaction data. All top suppliers report 100% on-time delivery, underscoring reliability in fulfillment.

FAQs

What materials can be used in custom forging?

Common materials include carbon steels (e.g., 45#), alloy steels (40CrNiMo, 42CrMo), stainless steels, aluminum alloys, copper, and brass. High-performance applications may use superalloys like GH4169. Supplier expertise varies—verify material availability and processing parameters before sourcing.

What is the typical MOQ for custom forged parts?

MOQ ranges from 1 piece for prototypes to 1,000+ pieces for production runs. Low-volume options are available from suppliers like Jiyuan Haiyuan and Qingdao Sande Tech, while others require larger batches to optimize tooling and setup costs.

How long does it take to receive custom forged components?

Lead times typically range from 20 to 35 days, including forging, heat treatment, machining, and inspection. Prototype orders may be completed in 15–20 days depending on complexity and supplier workload.

Can suppliers provide material certifications and test reports?

Yes, reputable suppliers offer material mill certificates, dimensional inspection reports, and hardness testing upon request. For critical applications, specify requirements for non-destructive testing (e.g., ultrasonic, magnetic particle) during quotation.

Do forging suppliers support design optimization?

Many suppliers provide engineering consultation to improve manufacturability, reduce material waste, and enhance structural integrity. Submit 2D/3D CAD files early in the process to enable feedback on draft angles, tolerances, and parting lines.