Custom Material Forging Services

Top sponsor listing

Top sponsor listing

0

0

1/34

1/34

1/3

1/3

CN

CN

1/10

1/10

1/3

1/3

0

0

CN

CN

1/20

1/20

CN

CN

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/37

1/37

1/3

1/3

1/3

1/3

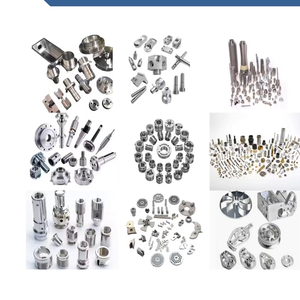

About custom material forging services

Where to Find Custom Material Forging Services Suppliers?

China remains a global hub for custom material forging services, with key manufacturing clusters in Shandong, Shanxi, and Guangdong provinces. These regions host vertically integrated facilities equipped with advanced hot and cold forging technologies, enabling production of high-strength components from carbon steel, alloy steel, stainless steel, aluminum, and titanium. Industrial zones in Qingdao (Shandong) and Zhongshan (Guangdong) offer specialized capabilities in precision die forging and OEM/ODM customization, supported by mature supply chains for raw materials and CNC machining post-processing.

Suppliers in these clusters benefit from concentrated technical expertise and infrastructure, allowing efficient scaling from prototype batches to high-volume orders. Average lead times range from 20–45 days depending on complexity, with localized access to heat treatment, surface finishing, and non-destructive testing services reducing outsourcing delays. Buyers gain cost advantages of 20–35% compared to Western suppliers due to lower labor costs and integrated production ecosystems within 50km radii encompassing foundries, machine shops, and logistics providers.

How to Choose Custom Material Forging Services Suppliers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

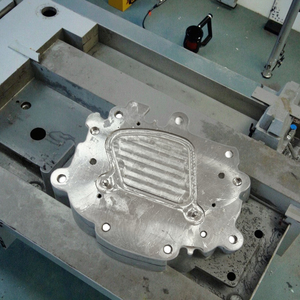

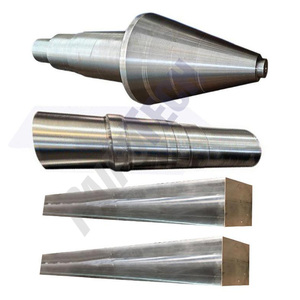

Technical & Process Capabilities

Confirm the use of standardized forging processes—hot forging for complex geometries and high-tensile applications, cold forging for tight tolerances and improved surface finish. Prioritize suppliers with in-house tooling design, CNC machining integration, and capacity to handle materials including 42CrMo, 20CrMoTi, T91/P91, and aerospace-grade alloys. Verification of process control documentation, such as forging diagrams and thermal treatment records, is essential for mission-critical components.

Quality Assurance Systems

While formal ISO 9001 certification is not explicitly stated in available data, performance indicators such as on-time delivery rates and transaction volume serve as proxies for operational maturity. Target suppliers with verified on-time delivery ≥97%, response times ≤4 hours, and evidence of repeat business (reorder rate >30%). Request material test reports (MTRs), dimensional inspection sheets, and third-party quality audit results where available.

Customization & Transaction Reliability

Assess customization depth beyond basic material and size adjustments. Leading suppliers support full OEM/ODM workflows, including logo imprinting, packaging specification, drawing-to-part conversion, and mold development. Evaluate digital responsiveness—sub-2-hour average reply times correlate with stronger client management—and review minimum order quantities (MOQs), which typically range from 10 to 1,000 pieces depending on part complexity and material type.

What Are the Best Custom Material Forging Services Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Customization Scope |

|---|---|---|---|---|---|---|---|

| Zhongshan Meichen Hardware Products Factory (Sole Proprietorship) | Forging, Machining, Casting, Motorcycle Systems | US $1,000+ | 100% | ≤4h | 100% | 10–1,000 pcs | Material, size, logo, packaging |

| Qingdao Sande Tech Co., Ltd. | Forging, Casting, Machining Services | US $20,000+ | 100% | ≤2h | Not Available | 1–10 pcs | Precision alloy, titanium, aluminum, conveyor chain systems |

| Taiyuan Realand Machinery Equipment Co., Ltd. | Diesel Engine Parts, Forged Rings, Steering Knuckles | US $9,000+ | 75% | ≤4h | <15% | 200–500 pcs | Color, material, size, logo, graphic, packaging |

| Qingdao Seger Industrial Co., Ltd. | Casting, Forging, Machining, Fasteners | US $90,000+ | 100% | ≤2h | <15% | 1,000 pcs | OEM brass/carbon steel forgings, galvanized metal |

| Shandong Meide Import And Export Co., Ltd. | Precision Forged Steel, Stainless Steel, Aluminum | US $220,000+ | 75% | ≤3h | 33% | 10–20 pcs | Alloy steel, carbon steel, aluminum, machined parts, mold specs |

Performance Analysis

Qingdao Sande Tech and Zhongshan Meichen stand out for responsiveness and reliability, both achieving 100% on-time delivery with rapid communication cycles. Sande Tech supports low MOQs starting at 1 piece, making it ideal for prototyping and small-batch customization in aerospace or medical sectors. Zhongshan Meichen’s 100% reorder rate indicates strong client retention, likely driven by flexibility in motorcycle system components and responsive service.

Qingdao Seger and Shandong Meide report the highest online transaction volumes (exceeding US $90,000), suggesting robust export activity and scalability. However, Seger’s sub-15% reorder rate may reflect transactional rather than relationship-based buyers, potentially indicating less engagement on engineering collaboration. Taiyuan Realand and Shandong Meide offer deep customization options, including mold design and material specification, though both show only 75% on-time delivery—warranting closer scrutiny of production planning controls.

FAQs

What materials are commonly used in custom forging services?

Standard materials include carbon steel (e.g., 20#–45#), alloy steels (42CrMo, 20CrMoTi), stainless steel (304, 316), aluminum alloys, and titanium. High-performance applications may require ASTM-specified grades such as T91/P91 or aerospace alloys. Confirm material traceability and availability of MTRs for compliance-critical industries.

What is the typical MOQ for custom forged parts?

MOQs vary significantly: simple components start at 1–10 pieces (e.g., precision aluminum forgings), while complex or high-setup-cost parts require 500–1,000 pieces. Suppliers like Qingdao Sande accommodate prototyping needs, whereas Qingdao Seger standardizes at 1,000-piece minimums for cost efficiency.

How long does it take to receive custom forged components?

Standard lead time ranges from 20–35 days after drawing approval, including tooling setup, forging, heat treatment, and finishing. Complex or large-scale forgings (e.g., steering knuckles, elevator parts) may extend to 45 days. Expedited timelines are possible with pre-existing molds or shared production runs.

Can suppliers provide samples before bulk production?

Yes, most suppliers offer sample production. Costs are typically borne by the buyer unless subsequent orders meet threshold volumes. Sample lead times average 10–20 days, depending on design complexity and material sourcing.

What certifications should I look for when sourcing forging services?

While explicit ISO 9001 certification is not disclosed in the dataset, prioritize suppliers demonstrating consistent on-time delivery (>95%), documented quality checks, and responsive communication. For regulated industries, request evidence of internal quality management systems, process validation records, and compliance with ASTM, DIN, or JIS standards.