Custom Press Forging Services

Top sponsor listing

Top sponsor listing

CN

CN

1/10

1/10

CN

CN

1/22

1/22

1/15

1/15

1/34

1/34

1/7

1/7

1/45

1/45

1/33

1/33

CN

CN

1/27

1/27

CN

CN

1/27

1/27

CN

CN

1/22

1/22

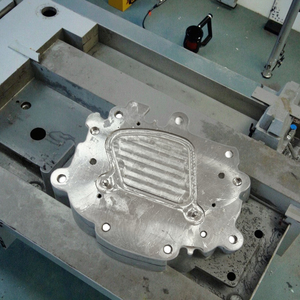

About custom press forging services

Where to Find Custom Press Forging Services Suppliers?

China remains a dominant force in the global custom press forging sector, with key manufacturing clusters concentrated in Shandong, Henan, and Zhejiang provinces. These regions host vertically integrated industrial ecosystems combining raw material access, heavy machining infrastructure, and streamlined logistics networks. Shandong benefits from proximity to major steel producers, enabling cost efficiencies for large-diameter and high-alloy forgings. Zhejiang’s Ningbo and Hangzhou zones specialize in precision components, supported by advanced CNC integration and rapid prototyping capabilities.

The clustering effect allows suppliers to offer competitive pricing—typically 20–35% below Western counterparts—while maintaining scalability for both low-volume specialized orders and high-volume industrial runs. Facilities commonly integrate casting, forging, heat treatment, and machining under one roof, reducing inter-facility delays. Lead times for standard custom forgings average 30–45 days, with expedited processing available for urgent orders. Buyers gain access to flexible MOQs, ranging from single-piece prototypes to bulk production runs exceeding 10,000 units.

How to Choose Custom Press Forging Services Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Verify adherence to international quality standards such as ISO 9001. While not all suppliers list certifications explicitly, consistent on-time delivery (≥97%) and documented process controls indicate robust quality management. For regulated industries (e.g., oil & gas, aerospace), confirm material traceability and compliance with ASTM, DIN, or ASME specifications.

Production Capability Assessment

Evaluate supplier capacity based on measurable indicators:

- Minimum order flexibility: Suppliers offering MOQs of 1–10 pieces cater to prototyping and niche applications

- Material expertise: Look for experience with carbon steel, alloy steel (e.g., 42CrMo4, 40CrNiMo), aluminum, and superalloys (e.g., GH4169)

- In-house machining and finishing capabilities to reduce outsourcing dependencies

Cross-reference response time (≤2 hours preferred) and reorder rates as proxies for service reliability and customer satisfaction.

Customization & Technical Support

Assess customization depth beyond basic dimensional adjustments. Leading suppliers support full-service engineering collaboration, including CAD/CAM file integration, material selection guidance, heat treatment specification, and packaging labeling. Rapid responders (<1–2h) are more likely to accommodate iterative design changes during development phases.

Transaction Security & Performance Metrics

Prioritize suppliers with verifiable performance data. On-time delivery rates at or near 100% correlate strongly with production stability. Use incremental ordering strategies—starting with small batches—to validate quality consistency before scaling. Where available, review online revenue tiers as an indicator of market presence and order volume handling capacity.

What Are the Best Custom Press Forging Services Suppliers?

| Company Name | Main Materials | MOQ Range | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Core Services |

|---|---|---|---|---|---|---|---|---|

| Ningbo Asaisi Industry & Trading Co., Ltd. | Aluminum, Carbon Steel, Alloy Steel | 10–1,000 pcs | $1–2.50 | 100% | ≤2h | 100% | US $10,000+ | Casting, Machining, Forging, Sheet Metal |

| Shandong Meide Import And Export Co., Ltd. | Alloy Steel, Carbon Steel, Aluminum | 10–20 pcs | $1–9.27 | 75% | ≤3h | 33% | US $210,000+ | Customized Forgings, Machined Parts |

| Qingdao Seger Industrial Co., Ltd. | Steel, Aluminum, Powder Metal | 1,000 pcs | $2–25 | 100% | ≤2h | <15% | US $80,000+ | Casting, Forging, Machining, Fasteners |

| Jiyuan Haiyuan Special Steel Co., Ltd. | 42CrMo, 40CrNiMo, GH4169, T91/P91 | 1–5 pcs | $25–680 | 100% | ≤1h | - | - | Precision Forging, Heavy-Duty Components |

| Henan Forging Emperor Industry Co., Ltd. | Steel, Carbon Steel | 1,000 pcs | $10–20 | 100% | ≤3h | <15% | US $2,000+ | Forging, Machining, Casting, Sheet Metal |

Performance Analysis

Suppliers like Ningbo Asaisi and Jiyuan Haiyuan demonstrate high reliability with 100% on-time delivery and strong responsiveness (≤2h and ≤1h, respectively). Jiyuan Haiyuan stands out for low-MOQ, high-value forgings in specialty alloys, making it ideal for aerospace and energy-sector clients requiring certified, small-batch production. Ningbo Asaisi combines broad service integration with a perfect reorder rate, indicating exceptional client retention.

In contrast, Qingdao Seger and Henan Forging Emperor offer economy-scale solutions suited for mass-produced industrial components, though lower reorder rates suggest room for improvement in post-sale satisfaction. Shandong Meide leads in reported online revenue (US $210,000+), reflecting significant market activity, but its 75% on-time delivery rate presents a risk factor for time-sensitive projects.

Buyers seeking prototype development should prioritize suppliers with sub-10-piece MOQs and fast response times. For serial production, evaluate total throughput capability and secondary processing availability to minimize supply chain complexity.

FAQs

How to verify custom press forging supplier reliability?

Assess on-time delivery history, response speed, and reorder rate as operational health indicators. Request material test reports (MTRs) and inspect process documentation for heat treatment, dimensional inspection, and non-destructive testing procedures. Conduct virtual audits via facility videos to confirm equipment and workflow maturity.

What is the typical MOQ for custom press forgings?

MOQs vary significantly: some suppliers accept as few as 1 piece for high-value components, while others require 1,000+ units for cost-effective production. Low-MOQ options are typically priced higher per unit but enable design validation and small-batch deployment.

What materials are commonly used in press forging services?

Carbon steel (e.g., ASTM A283), alloy steels (42CrMo4, 40CrNiMo), stainless steels (A182 F9/F11/F22), tool steels, aluminum alloys, and nickel-based superalloys (GH4169) are widely processed. Material selection depends on mechanical requirements, corrosion resistance, and operating temperature.

Do suppliers support full customization?

Yes, most offer comprehensive customization including geometry, tolerances, surface finish, heat treatment, packaging, and labeling. Advanced providers support GD&T specifications, 3D model submissions, and co-engineering for complex applications.

What are the lead times for custom forging orders?

Standard lead times range from 30 to 45 days after design approval. Prototype deliveries may take 15–25 days. Factors influencing duration include part complexity, material availability, required certifications, and post-forging operations such as CNC machining or coating.