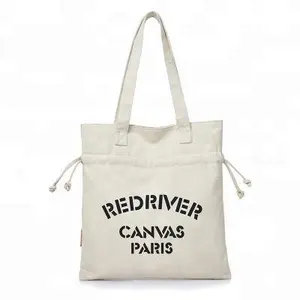

Custom Print Tote Bag Producer

1/9

1/9

1/15

1/15

1/14

1/14

1/11

1/11

1/15

1/15

1/10

1/10

1/21

1/21

1/6

1/6

1/16

1/16

1/13

1/13

About custom print tote bag producer

Where to Find Custom Print Tote Bag Producers?

China remains the global epicenter for custom print tote bag manufacturing, with key production hubs in Guangdong, Zhejiang, and Yiwu offering specialized capabilities in textile printing, material sourcing, and mass customization. These regions host vertically integrated facilities that manage every stage of production—from fabric weaving and dyeing to digital/screen printing and packaging—enabling end-to-end control over quality and lead times.

Suppliers in these clusters benefit from proximity to raw material markets and logistics gateways, reducing input costs by 15–25% compared to non-specialized regions. The concentration of skilled labor and advanced printing technologies allows for scalable output, with leading producers capable of fulfilling orders exceeding 100,000 units monthly. Buyers gain access to flexible MOQs (as low as 100 pieces), rapid prototyping, and diverse material options including organic cotton, non-woven polypropylene, canvas, and recycled fabrics.

How to Choose Custom Print Tote Bag Suppliers?

Selecting a reliable supplier requires evaluating three core dimensions: production capability, quality assurance, and transaction reliability.

Production & Customization Capacity

Confirm suppliers operate their own production lines and offer comprehensive customization:

- Material options: Cotton, canvas, non-woven, jute, polyester, or organic/recycled textiles

- Printing techniques: Screen printing, heat transfer, sublimation, embroidery, or offset printing

- Customizable elements: Size, color, logo placement, pocket design, lining, handles, and packaging

- Digital mockup services and pre-production sample availability within 5–7 days

Cross-reference stated capabilities with product listings and customer reviews to verify consistency.

Quality Management & Compliance

While formal certifications (e.g., ISO 9001, OEKO-TEX, BCI) are not universally listed, prioritize suppliers demonstrating structured quality controls:

- On-time delivery rates ≥98%

- Response times ≤2 hours for initial inquiries

- Documented inspection processes for print alignment, seam strength, and colorfastness

- Compliance with environmental standards for dyes and inks (especially for EU/US markets)

Transaction Reliability & Risk Mitigation

Assess supplier credibility through verifiable performance metrics:

- Use platform-backed transaction systems where available to secure payments until delivery confirmation

- Prioritize suppliers with reorder rates above 20%, indicating customer retention and satisfaction

- Request physical or digital samples before bulk ordering to evaluate material feel, print resolution, and construction quality

- Clarify FOB terms, packaging specifications, and shipping timelines during negotiation

What Are the Top Custom Print Tote Bag Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | MOQ Range | Price Range (USD) | Customization Scope |

|---|---|---|---|---|---|---|---|---|

| Jcbasic Garment Accessories (Shanghai) Co., Limited | Shanghai, CN | US $320,000+ | 98% | ≤2h | <15% | 100–200 pcs | $0.08–1.80 | Color, material, size, logo, packaging, graphic |

| Choieon Gifts Co., Limited | Guangdong, CN | US $280,000+ | 98% | ≤5h | 20% | 100–200 pcs | $0.59–1.97 | Color, fabric, logo, embroidery, print, design, packaging |

| Yiwu Siicoo Trade Co., Ltd. | Yiwu, CN | US $100,000+ | 90% | ≤2h | 21% | 100–200 pcs | $0.31–2.15 | Multiple textile and packaging products |

| Wuhan New Speed International Logistics Co., Ltd. | Wuhan, CN | US $7,000+ | 100% | ≤3h | 20% | 500 pcs | $0.72/unit | Color, fabric, size, logo, pattern, packaging |

| Guangzhou Glorious Development Co., Ltd. | Guangzhou, CN | US $170,000+ | 100% | ≤1h | 20% | 50–300 pcs | $0.55–2.20 | Color, fabric, logo, pocket, compartment, embroidery |

Performance Analysis

Guangzhou Glorious Development stands out for responsiveness (≤1h) and flexibility with lower MOQs (50 pieces), making it ideal for small-batch or trial orders. Jcbasic offers the widest price range and lowest entry cost ($0.08/unit), suitable for budget-conscious buyers prioritizing volume. Choieon and Yiwu Siicoo provide broad customization across materials and print methods, supported by strong transaction histories. Wuhan New Speed reports perfect on-time delivery but enforces a high MOQ (500 pcs), aligning with large-scale campaigns. Notably, multiple suppliers indicate “own production line” capabilities, reducing reliance on third-party contractors and improving quality traceability.

FAQs

How to verify a custom tote bag supplier’s production claims?

Request facility videos or virtual audits showing cutting, sewing, and printing stations. Verify ownership of equipment such as screen printing frames or digital printers. Cross-check product consistency across listings and confirm whether the company is labeled as a manufacturer versus a trading entity.

What is the typical lead time for custom printed tote bags?

Standard production lead times range from 15 to 25 days after sample approval. Rush orders may be completed in 10–12 days at an additional cost. Add 5–10 days for air freight or 25–40 days for sea shipping depending on destination.

Can suppliers accommodate eco-friendly materials and certifications?

Yes, many producers offer GOTS-certified organic cotton, recycled PET, or biodegradable non-woven fabrics. For compliance with EU or North American sustainability standards, request documentation on ink composition, water-based dyes, and factory waste management practices.

Do custom print tote bag suppliers provide free samples?

Sample policies vary. Some suppliers offer paid samples ($10–$30) refundable upon order placement. Fully free samples are rare but possible for high-volume prospects. Digital mockups are typically provided at no cost.

What are common MOQs and pricing factors?

MOQs range from 50 to 500 units depending on the supplier and complexity. Key pricing variables include fabric weight (e.g., 6 oz vs. 10 oz cotton), number of print colors, bag dimensions, and finishing options (e.g., zippers, reinforced stitching). Bulk orders (10,000+ units) can reduce unit costs by 20–40%.