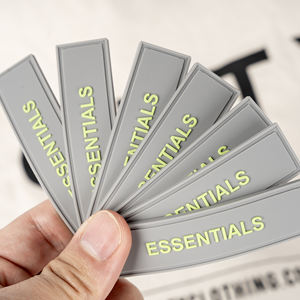

Custom Rubber Patches No Minimum

Top sponsor listing

Top sponsor listing

1/14

1/14

1/14

1/14

1/28

1/28

1/11

1/11

1/28

1/28

1/4

1/4

1/17

1/17

1/12

1/12

1/52

1/52

1/22

1/22

1/7

1/7

1/29

1/29

1/29

1/29

1/12

1/12

About custom rubber patches no minimum

Where to Find Custom Rubber Patches No Minimum Suppliers?

China remains the central hub for low-volume, high-customization rubber patch manufacturing, with key production clusters in Guangdong Province—particularly Shenzhen, Dongguan, and Zhongshan. These regions host vertically integrated facilities specializing in soft enamel, PVC, silicone, and TPU-based patches, enabling rapid prototyping and small-batch production without minimum order constraints. The concentration of material suppliers, mold designers, and digital printing units within 50km radii supports agile manufacturing cycles ideal for startups, promotional campaigns, and niche apparel brands.

Suppliers in this ecosystem leverage automated die-cutting, UV-resistant screen printing, and heat-activated adhesive lamination lines to deliver durable, weatherproof patches. Many operate dual production models: mass customization for e-commerce clients and precision batch runs for military, outdoor gear, and uniform sectors. Buyers benefit from localized supply chains that reduce lead times by 20–30% compared to offshore alternatives, while maintaining compliance with international standards for colorfastness, wash resistance, and non-toxic materials.

How to Choose Custom Rubber Patches No Minimum Suppliers?

Effective supplier selection requires verification across three core dimensions:

Production & Customization Capability

Confirm access to in-house tooling and molding equipment for rapid design iteration. Leading suppliers offer full digital workflows—from vector artwork conversion to 3D mockups—within 24 hours. Evaluate supported techniques: embossing, debossing, glow-in-the-dark pigments, laser cutting, and multi-layer laminates. Suppliers should accommodate backing types including iron-on, sew-on, Velcro, magnetic, and adhesive (3M/TPU).

Quality Assurance & Compliance

While formal ISO certification is less common among micro-MOQ specialists, prioritize partners with documented QC protocols for dimensional accuracy, edge durability, and color consistency. Request test reports for RoHS and REACH compliance, especially for exports to EU and North American markets. Verify use of UV-stable inks and waterproof substrates to ensure longevity under outdoor exposure.

Transaction Reliability Metrics

Analyze performance indicators such as on-time delivery rate (>97%), reorder frequency (>30%), and response time (≤3 hours). High online transaction volume (exceeding US $200,000 annually) correlates with operational stability and customer service infrastructure. Cross-reference product listings with actual sample outputs to assess fidelity between advertised and delivered quality.

What Are the Best Custom Rubber Patches No Minimum Suppliers?

| Company Name | Location | Main Products | Min. Order | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Dongguan Lin Wang Garment Accessory Co., Ltd. | Dongguan, CN | Rubber, PVC, embroidered, heat transfer, velcro-backed patches | 50 pieces | $0.13–0.89 | 98–99% | ≤2–3h | 30–34% | US $590,000+ |

| Changsha Davina Patches Co.,Ltd. | Changsha, CN | Soft rubber, PVC, iron-on, reflective, digital print patches | 10 pieces | $0.30 | 99% | ≤3h | 33% | US $420,000+ |

| Zhongshan Wantai Crafts Gifts Co., Ltd. | Zhongshan, CN | Rubber, PVC, iron-on, embroidered, debossed, molded patches | 10–100 pieces | $0.10–1.22 | 97% | ≤3h | 25% | US $630,000+ |

| Shenzhen Dansky Manufacture Technology Co., Ltd. | Shenzhen, CN | Rubber, hook & loop tapes, webbing, fabric belts | Data not available | Data not available | 100% | ≤4h | 33% | US $20,000+ |

Performance Analysis

Dongguan Lin Wang stands out for breadth of customization options and consistent delivery performance across high-volume transactions. Changsha Davina offers the lowest MOQ (10 pieces) with standardized pricing, streamlining procurement for micro-orders. Zhongshan Wantai leads in revenue volume and material diversity but shows a lower reorder rate, suggesting potential gaps in post-sale satisfaction. Shenzhen Dansky, despite limited public product data, maintains perfect on-time delivery, indicating strong logistics control. Buyers seeking ultra-low MOQs should prioritize Changsha and Zhongshan-based suppliers, while those requiring complex designs at scale benefit from Dongguan’s technical depth.

FAQs

What is the typical lead time for custom rubber patches with no minimum?

Standard production lead time ranges from 7 to 15 days after artwork approval. Rush orders with expedited shipping can be fulfilled in 5–7 days, depending on complexity and finishing requirements.

Are free samples available?

Most suppliers offer digital proofs at no cost. Physical samples are typically charged but may be credited toward first production orders. Expect sample fees between $10–$30, excluding shipping.

Can I customize shape, thickness, and backing type?

Yes. Full customization includes irregular die-cut shapes, thicknesses from 0.8mm to 3.0mm, and multiple backing options (iron-on, sew-on, Velcro, adhesive). 3D domed finishes and glow-in-the-dark effects are also widely supported.

Do these suppliers support private labeling and individual packaging?

Yes, most offer blank backings, custom labels, and individual polybagging or blister packaging. Some provide mockup services for marketing use.

How are quality issues resolved?

Reputable suppliers accept returns or reprints for defects in printing, cutting, or adhesion. Clear photo documentation is required within 7 days of receipt. Dispute resolution is typically managed directly or through transaction platforms with buyer protection policies.