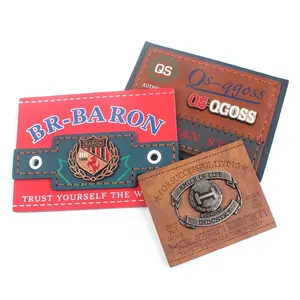

Custom Rubber Tags

About custom rubber tags

Where to Find Custom Rubber Tags Suppliers?

China remains the dominant hub for custom rubber tag manufacturing, with key production clusters in Guangdong and Zhejiang provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable production of silicone, PVC, and eco-friendly rubber materials. Dongguan and Zhongshan in Guangdong are particularly notable for their specialization in fashion accessories and garment labeling solutions, offering advanced processing techniques such as 2D/3D embossing, UV printing, hot stamping, and injection molding.

Suppliers in these industrial zones benefit from proximity to raw material suppliers and logistics networks, enabling lead times averaging 15–25 days for customized orders. The concentration of technical expertise allows for high flexibility in design customization, including shape, color, thickness, logo replication, and packaging configuration. Buyers gain access to cost-efficient production, with unit prices ranging from $0.01 to $1.50 depending on complexity, material selection, and order volume.

How to Choose Custom Rubber Tags Suppliers?

Selecting a reliable supplier requires due diligence across three core areas:

Production & Customization Capabilities

Verify that suppliers offer in-house tooling, mold development, and graphic design support. Key capabilities include die-cutting, plating, holographic foil application, and dual-sided printing. Confirm compatibility with requested materials—silicone, PVC, or recyclable rubber—and assess design flexibility for logos, text, and branding elements. Suppliers with dedicated R&D teams can better accommodate complex configurations such as 3D raised surfaces or iron-on adhesive backing.

Quality Assurance & Compliance

While formal certifications (e.g., ISO 9001, RoHS) are not universally listed, performance metrics indicate strong operational reliability. Prioritize suppliers with documented on-time delivery rates exceeding 97% and response times under 4 hours. Reorder rates above 25% suggest customer satisfaction with product consistency and service quality. For export-bound orders, ensure compliance with destination-market regulations regarding material safety and labeling standards.

Order Flexibility & Transaction Security

Minimum Order Quantities (MOQs) vary significantly—from 50 to 1,000 pieces—allowing scalability for both startups and established brands. Lower MOQs (50–100 units) facilitate sampling and small-batch testing. Evaluate suppliers based on transparent pricing structures, packaging customization options, and participation in transaction protection programs. Pre-shipment inspections and sample validation are recommended before full-scale production.

What Are the Top Custom Rubber Tags Suppliers?

| Company Name | Specialization | Min. Order | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier | Verification |

|---|---|---|---|---|---|---|---|---|

| Zhongshan Aosheng Garment Accessories Co., Ltd. | 2D/3D PVC, Luggage Tags, Circular Silicone | 50 pieces | $0.11–0.47 | 99% | ≤3h | 28% | US $80,000+ | Multispecialty Supplier |

| Dalian Yima Garment Accessories Co., Ltd. | Garment Labels, Swing Tags, Iron-On Logos | 300–1,000 pieces | $0.04–0.32 | 98% | ≤4h | 31% | US $190,000+ | Not Specified |

| Dongguan Hongyou Packaging Products Co., Ltd. | Eco-Friendly PVC, Hollow Swing Tags, UV Printing | 100 pieces | $0.01–0.15 | 98% | ≤1h | 18% | US $80,000+ | Custom Manufacturer |

| Zhongshan Wantai Crafts Gifts Co., Ltd. (Profile 1) | Soft Rubber Badges, 3D Epoxy, Travel Tags | 100 pieces | $0.20–1.18 | 97% | ≤3h | 25% | US $630,000+ | Brand Holder |

| Zhongshan Wantai Crafts Gifts Co., Ltd. (Profile 2) | Promotional Tags, Embossed Designs, Insert Cards | 50 pieces | $0.10–1.50 | 99% | ≤3h | 24% | US $150,000+ | Brand Holder |

Performance Analysis

Zhongshan Aosheng and Dalian Yima demonstrate strong reliability with 98–99% on-time delivery and reorder rates above 25%, indicating consistent buyer retention. Dongguan Hongyou stands out for low-cost production ($0.01 minimum price) and rapid response times (≤1 hour), ideal for time-sensitive inquiries. Zhongshan Wantai, operating under dual profiles, serves niche markets with premium soft rubber and epoxy-finished tags at higher price points, reflecting specialized craftsmanship. Suppliers with lower reorder rates may prioritize broad market reach over long-term client relationships, warranting closer evaluation of sample quality and communication consistency.

FAQs

What materials are commonly used for custom rubber tags?

The primary materials are silicone, PVC, and eco-friendly recyclable rubber. Silicone offers durability and flexibility, suitable for luggage and promotional tags. PVC enables sharp 2D/3D detailing and is widely used in garment labels. Recyclable variants are increasingly available for sustainable branding initiatives.

What is the typical lead time for custom rubber tag production?

Standard lead times range from 15 to 25 days after sample approval. Simple designs with existing molds may ship faster, while custom molds or intricate finishes (e.g., holographic foiling) can extend timelines by 7–10 days.

Can I request a sample before placing a bulk order?

Yes, most suppliers offer samples, often within 5–10 days. Some waive fees for potential large-volume buyers, while others charge a nominal fee covering material and labor. Sample costs typically range from $10 to $50 depending on complexity.

Are there options for environmentally friendly rubber tags?

Yes, several suppliers provide eco-friendly alternatives using recyclable PVC or biodegradable rubber compounds. Look for terms like “eco-friendly,” “recyclable,” or “low-impact dyes” in product descriptions. These options align with sustainability goals in fashion, travel, and corporate gifting sectors.

How do MOQs affect pricing and customization?

Lower MOQs (50–100 units) allow for design testing but result in higher per-unit costs. Bulk orders (500+ units) reduce unit prices significantly and enable full customization, including custom mold development. Negotiate tiered pricing based on projected annual volumes to optimize long-term sourcing efficiency.