Customize Machine Maker

Top sponsor listing

Top sponsor listing

1/3

1/3

1/2

1/2

CN

CN

1/18

1/18

1/34

1/34

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/6

1/6

1/19

1/19

1/3

1/3

1/26

1/26

0

0

1/3

1/3

1/17

1/17

1/23

1/23

1/13

1/13

CN

CN

0

0

About customize machine maker

Where to Find Customize Machine Maker Suppliers?

China remains the central hub for custom machine manufacturing, with key production clusters in Fujian, Xiamen, Dongguan, and Taiyuan offering specialized capabilities in precision engineering and industrial fabrication. These regions host vertically integrated facilities that combine CNC machining, sheet metal fabrication, casting, and mold design under one roof, enabling end-to-end customization from concept to delivery. The concentration of skilled labor, material suppliers, and logistics networks allows for rapid prototyping and scalable production runs.

Suppliers in these zones typically operate within ecosystems where component sourcing, processing, and quality control are localized within 50–100 km radii. This integration reduces lead times by up to 30% compared to decentralized manufacturing models. Buyers benefit from flexible MOQs—ranging from single prototypes to multi-ton batch orders—and access to advanced processing techniques including 3–5 axis CNC milling, stamping, anodizing, and electroless nickel plating. Average production lead times range from 15–35 days depending on complexity, with express services available for urgent requests.

How to Choose Customize Machine Maker Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Customization Capability

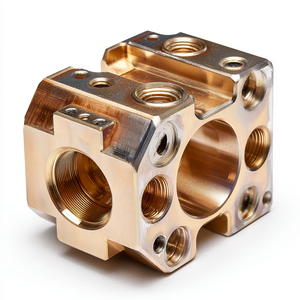

Confirm the supplier supports your required materials (e.g., hardened steel, aluminum, brass, copper) and processes (CNC machining, injection molding, sheet metal stamping). Review their ability to interpret technical inputs such as STP files, 3D drawings, CAD models, and graphic specifications. Suppliers offering mold design, color finishing, weight adjustment, and packaging customization demonstrate higher engineering maturity.

Production Infrastructure Verification

Assess core operational metrics:

- Facility size and equipment capacity (in-house CNC, turning, milling, welding, and surface treatment lines preferred)

- Dedicated R&D or engineering teams capable of design validation and DFM feedback

- Monthly output scalability for both prototype and mass production phases

Cross-reference response time (target ≤2 hours) and on-time delivery rate (ideal ≥97%) as indicators of operational efficiency.

Quality Assurance & Compliance

While ISO 9001 certification is not universally listed, prioritize suppliers who document quality control procedures and provide inspection reports. For export-bound components, ensure compliance with destination-market standards (e.g., CE, RoHS, REACH). Request sample testing protocols for dimensional accuracy, material hardness, and surface finish consistency before scaling orders.

What Are the Best Customize Machine Maker Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Fuzhou Jiahexing Machinery Co., Ltd. | Machining Services, Moulds, Sheet Metal Fabrication, Aviation Parts | Material, size, logo, mold design, 3D drawings, color, packaging, label, weight | 100% | ≤2h | 33% | $110,000+ | Varies | N/A |

| Xiamen Openex Mechanical Technology Limited | Machining Services, Sheet Metal Fabrication, Casting, Sorting Machines | Limited explicit options; OEM-focused large structures and frames | 100% | ≤5h | - | - | 1 ton | $1,100–2,500 |

| JUNYING METAL MANUFACTURING CO., LIMITED | CNC Machining Services, Precision Metal Parts | Aluminum, steel, copper, brass; custom hardware; high-precision tolerances | 100% | ≤2h | - | - | 1 piece | $1–20.50 |

| Jingqi Precision Hardware (Dongguan) Co., Ltd. | High-Precision CNC Machining, Stainless Steel Components | 3–5 axis machining, anodizing, custom stainless steel parts | 100% | ≤2h | <15% | $420,000+ | 2 pieces | $0.40–2.00 |

| Taiyuan Realand Machinery Equipment Co., Ltd. | Custom Metal Components, Automotive & Aviation Parts | Forging, 3D drawings, logo, packaging, color, material selection | 75% | ≤4h | <15% | $9,000+ | 1 piece / 200 pieces / 1kg | $0.60–50 |

Performance Analysis

Fuzhou Jiahexing stands out with a 33% reorder rate and extensive customization breadth, indicating strong customer retention and engineering flexibility. Jingqi Precision Hardware leads in online revenue ($420,000+) and offers highly competitive pricing for small-batch precision parts, though its reorder rate suggests room for service improvement. Xiamen Openex specializes in heavy structural components with ton-level minimums, making it suitable for large-scale industrial builds. JUNYING METAL provides low-MOQ solutions ideal for prototyping, while Taiyuan Realand, despite lower on-time performance (75%), supports diverse material and forging-based customization. All top-tier suppliers maintain sub-5-hour response times, with three achieving ≤2h—a critical factor for iterative design collaboration.

FAQs

How to verify customize machine maker reliability?

Evaluate documented quality control processes, request facility videos or audit reports, and validate technical communication speed and clarity. Prioritize suppliers with consistent on-time delivery records (>95%) and verifiable transaction histories. Third-party inspection services can be deployed pre-shipment for high-value orders.

What is the typical sampling timeline for custom machines or parts?

Standard samples take 7–15 days for machining and fabrication. Complex designs involving mold creation or multi-axis programming may require 20–30 days. Add 5–10 days for international air shipping. Expedited services are available at premium rates.

Can suppliers handle global shipping and customs compliance?

Yes, experienced manufacturers manage export logistics, including documentation, packaging, and incoterms negotiation (FOB, CIF). Buyers should confirm adherence to destination-country regulations, especially for machinery with electrical or moving components requiring CE or UL marking.

Do customize machine makers offer free samples?

Free samples are rare for custom-engineered parts. Most suppliers charge full or partial cost recovery for initial units. Sample fees may be credited toward future bulk orders, typically those exceeding 500 units or $5,000 in value.

How to initiate a customization request effectively?

Submit complete technical packages including 2D/3D drawings (STP, DWG, PDF), material specifications, tolerance requirements, surface finish preferences, and functional testing criteria. Clear documentation reduces iteration cycles and accelerates quotation and prototype delivery.